Access the Latest Technology With Construction Rentals

Technology continues to transform the construction industry. From advanced GPS systems to automated machine controls, modern tools help contractors work faster, safer, and more profitably. Construction equipment rental technology gives you access to the latest features without the long-term investment.

Why Technology in Equipment Rentals Matters

The equipment you bring to a job can determine whether you win contracts. Clients want safe, accurate, and efficient work. Companies with the latest technology have a built-in advantage. Here are some of the top benefits of using modern technology in rental equipment:

- Greater efficiency: GPS and machine automation enable operators to finish jobs in fewer passes.

- Improved safety: Cameras and detection systems warn operators of hazards.

- Better data: Telematics and sensors track performance, maintenance needs, and fuel use.

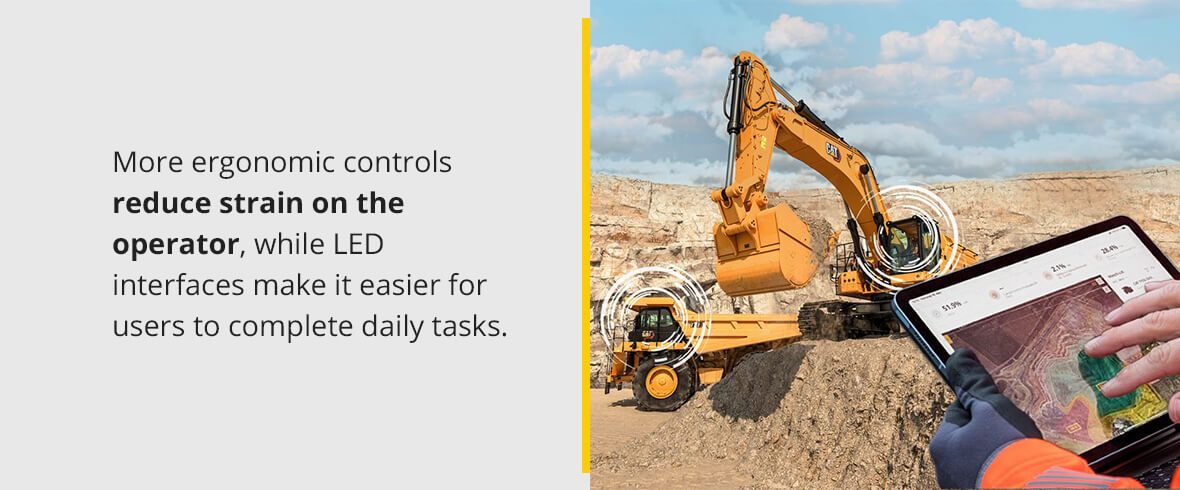

- Operator comfort: Ergonomic controls, climate systems, and intuitive displays reduce fatigue.

Access the Latest Technology by Renting

Renting lets you use new technology soon after it’s available. Instead of being tied to older machines, you can test out upgrades and enjoy productivity, efficiency, and safety improvements right away. Rental benefits include:

- No long-term commitments, test before you buy

- Access to the newest models and features

- Ability to choose technology on a project-by-project basis

- Competitive advantage when bidding on projects

- Cost savings compared to purchasing

Examples of the Latest Construction Technology

The Cat® Rental Store offers a wide selection of technology solutions. These systems improve safety, accuracy, productivity, and profitability.

1. Hybrid and electric machines reduce fuel costs and emissions. Rentals give you early access to these eco-friendly options without waiting to purchase new fleets.

2. Telematics technology collects data on machine health, fuel use, idle time, and location. This information helps managers cut waste, schedule maintenance, and improve fleet efficiency. Telematics also prevents theft with geo-fencing and real-time alerts.

3. Cat® VisionLink® connects your machines, operators, and data into one central hub. Through mobile and web apps, you can track hours, location, and condition to make informed decisions and extend fleet life.

4. Cat Grade uses automated guidance to help operators grade more accurately. Options include 2D systems for flat planes and slopes or 3D systems for complex designs. The result is faster grading with fewer passes and higher accuracy.

5. Cat Payload technology measures loads in real time. Operators can hit targets faster and avoid overloading. Reports track productivity metrics like tons per hour or fuel burned.

6. Cat Detect uses cameras, sensors, and radar to keep operators aware of their surroundings. It reduces blind spots, prevents accidents, and enhances jobsite safety.

7. Cat Compact provides in-cab feedback to ensure precise compaction. Operators achieve uniform density with fewer passes, saving fuel and labor.

8. Cat Command enables remote equipment control. Operators can run machines from safe distances, improving productivity and reducing risks in hazardous areas.

The Benefits of Technology in Rental Equipment

Technology-enabled rentals provide advantages across the board:

- Safety: Prevent accidents with alerts and detection.

- Productivity: Complete tasks more quickly and accurately.

- Quality: Deliver precise, consistent results that impress clients.

- Fuel efficiency: Burn less fuel and reduce operating costs.

- Comfort: Reduce operator fatigue with ergonomic features and automation.

- Cost savings: Lower expenses on fuel, maintenance, and labor.

- Machine life: Less wear and tear extends equipment longevity.

Stay Ahead with The Cat® Rental Store

With rentals, you can stay current with new technology and keep your business competitive. Explore Caterpillar’s latest construction technology and browse available rental equipment. Find your nearest location to start using technology-driven rentals today.

Find The Cat Rental Store Near You