When to Use Different Concrete Saw Types

With various concrete saw types available, choosing the right one for each project is essential. Concrete chainsaws, handheld saws, walk-behind saws, and wall saws each offer unique capabilities and advantages that make them ideal for different applications. Before renting or purchasing a saw, you must also consider the ideal blade type and power source for your tasks and jobsite.

Jump to a section:

The Basics of Concrete Saws

Concrete saws are also known as consaws or road saws, and they cut through hard matter. You can use a concrete saw when you need to work with the following types of materials:

- Tile

- Brick

- Asphalt

- Stone blocks

- Metal

If you need to cut recently poured concrete to control shrinkage cracks, you can typically start between three and six hours after pouring it. However, the best time to start cutting depends on the weather. You should wait longer in colder temperatures because concrete needs more time to cure and strengthen. Leaving concrete to settle overnight before cutting is common.

Before cutting, you should make small trail cuts to check for raveling. You can start cutting as soon as you notice the raveling stop.

When to Use Concrete Saws

The following types of concrete saws serve specific purposes and applications:

1. Concrete Chainsaws

You can use a concrete chainsaw to cut square corners and sharp angles in stone, bricks, blocks, and concrete. A concrete chainsaw uses cutting teeth on a diamond-coated chain. Water cools the chain, which follows the oblong blade's perimeter. A concrete chainsaw's small size makes it perfect for reaching challenging areas. You can use a concrete chainsaw for:

- Demolition: Concrete chainsaws are incredibly useful in demolition because you can use them to break up and remove significant concrete sections quickly. A concrete chainsaw is an excellent demolition saw alternative because it offers more control, precision, and efficiency. Enhanced control reduces operator fatigue when making numerous cuts, and it increases safety. Additionally, a concrete saw's durability enables you to make more cuts before replacing the chain.

- Cutting windows, doors, and beam pockets: A concrete chainsaw is ideal for cutting square corners because it provides the necessary cutting depth without over-cutting. With this type of saw, you can cut precise openings for door, window, and beam pocket installation.

- Creating expansion joints: Expansion joints are essential for preventing concrete from pushing and cracking the materials that surround it. To create expansion joints, you must make cuts and install bituminous material that allows the concrete the grow without causing damage. A concrete chainsaw enables you to cut while controlling cracking to prevent surface damage.

- HVAC and electrical work: A concrete chainsaw is also an excellent choice for completing heating, ventilation, air conditioning (HVAC), and electrical work. The chainsaw's power, precision, and cutting depth make it easy to remove sections of the wall, cut perfect corners, and install electrical or HVAC equipment.

2. Handheld Saws

A handheld saw is compact and can cut through concrete, metal, and asphalt using a circular diamond blade. Handheld concrete saws are also versatile, enabling you to use them for various tasks such as:

- Cutting through concrete floors or walls

- Electrical and plumbing installation purposes

- Demolishing infrastructure wreckage and concrete

- Masonry applications

- Cutting building components for onsite adjustment purposes

You can quickly cut and adjust onsite building components with a smaller handheld saw. A handheld saw offers excellent control, and it comes in the following variations:

- Cut-off saw: A cut-off saw features an abrasive, circular blade that typically measures between 13 and 14 inches. It's easy to move around your jobsite, and it's an excellent choice for cutting concrete, asphalt, and pipes. Users often rely on cut-off saws to cut wall openings or complete surface jobs such as cutting holes in concrete slabs.

- Table saw: A concrete table or tile saw is similar to a handheld cut-off saw, but its primary application is cutting ceramic tiles. You can also use a tile saw as a tile cutter alternative. Tile saws make more precise cuts than tile cutters can.

3. Walk-Behind Saws

Walk-behind saws are also known as street or floor saws, and they are wheeled so you can push them from behind. You can use these heavy-duty saws to cut straight lines on asphalt, concrete floors, sidewalks, driveways, and slabs, and they come in self-propelled models for easier movement and cutting.

A walk-behind saw is typically faster than a handheld saw, and it's ideal for various applications such as:

Creating Inlays and Grooves

Inlays and grooves are an essential part of concrete installation processes. You can use a walk-behind concrete saw to create inlays and grooves for the following purposes:

- Skid resistance: A walk-behind saw is an excellent choice if you need to perform pavement grooving on roads. Grooves create friction when roads are wet, icy, or snow-covered, and they provide spaces for precipitation accumulation to drain. Using the right equipment can help you create groove widths that meet specifications, and a walk-behind saw is an excellent way to do so efficiently.

- Concrete crack prevention: Construction cuts can help prevent cracking after you pour concrete. When your concrete strengthens enough to maintain a clean-cut surface but is still soft enough to cut through, you can use a walk-behind saw to create cuts and fill them with grout.

- Control joints: You can also use a walk-behind concrete saw to control cracking. You can cut smooth control joints and give your poured concrete space to crack where it's not visible.

Trenching

Creating trenches for electrical and plumbing conduit utilities requires the right equipment and skill. A walk-behind saw is an excellent option for larger trenching applications because it creates smooth, deep cuts and puts pressure on the work surface to break shallow roots.

Road Repair

A walk-behind saw's cutting depth and power make it perfect for road repair. Adding a heavy-duty walk-behind saw to your fleet can help you complete asphalt repair work efficiently.

Driveway or Large Floor Expansion

You should consider adding a walk-behind concrete saw to your fleet if you perform driveway and large floor expansions. A walk-behind saw allows you to cover large surface areas faster than you could with a handheld saw.

Defining Edges

A walk-behind concrete saw is essential if you need to remove and replace deteriorated sections of concrete or asphalt. Walk-behind concrete saws offer excellent precision, allowing you to define edges effectively when you remove worn areas.

Patch Repairs

Walk-behind concrete saws are also ideal for completing patch repairs. Their ability to define precise edges makes them perfect for cutting a repair area's outer boundaries.

4. Wall Saws

Concrete wall saws are track-mounted saws that make precise cuts in sloped or vertical hard surfaces, and they typically feature diamond blades. You can use a concrete wall saw to make horizontal or vertical cuts in cinder block, asphalt, concrete, or stone. Due to their design and capabilities, concrete wall saws are ideal for the following types of applications:

- Cutting apertures: A wall saw's cutting depth enables it to cut up to 30 inches into asphalt, concrete, stone, or cinder block, making it an excellent choice for cutting wall and door openings. If you need to cut deeper than 30 inches, you can cut from both sides of a material with the saw to reach a depth of 60 inches. Wall saws also offer excellent precision so you can create clean, smooth cuts to meet building specifications.

- Bevel cutting for chamfered edges: Chamfered edges look tidier than sharp edges, and they help prevent injuries and damage. A wall saw offers the precision and control necessary to create chamfered edges.

- Cutting expansion and control joints: Similar to concrete chainsaws and walk-behind concrete saws, you can use a wall saw to cut materials for expansion and control joints. A wall saw is the ideal choice if you need to cut expansion and control joints in vertical structures.

Types of Concrete Saw Blades

The right type of blade for your concrete saw depends on the materials you work with and your specific application. Consider these blade types to determine the best option for your next project:

Diamond

A diamond blade features a steel core embedded with synthetic diamond particles. It is highly durable, delivers top performance, and withstands high temperatures. If you fit your concrete saw with a diamond blade, you can choose one of the following types:

- Continuous-rim: A continuous-rim blade is the best option if you need to make slow, precise cuts in marble, porcelain, tile, or granite. Continuous-rim blades are wet blades that cool via a water stream during operation. With a continuous-rim blade, you can expect smooth, clean cuts with minimal dust.

- Turbo-rim: Turbo-rim blades are ideal for making fast, clean cuts in masonry, concrete, tile, brick and stone. A turbo-rim blade has a serrated, continuous rim, and you can use it for dry or wet cuts. If you perform dry cutting, you will make repeated small cuts in a material.

- Segmented: Segmented concrete saw blades make uneven, rough cuts in asphalt, concrete, limestone, and brick. A segmented blade features diamond segments with gaps in between, helping it cool and remove debris faster. You can use a segmented blade wet or dry.

Abrasive

Abrasive blades are circular blades, also known as abrasive cutoff wheels. They consist of aluminum oxide and silicon carbide, helping them cut through softer matter such as brick, green concrete, and asphalt. They're less durable than diamond blades and produce a considerable amount of dust during operation. If you use an abrasive blade, try to choose one reinforced with a strong bonding agent like fiberglass to prevent cracking and shattering.

Concrete Saw Power Sources

The power source you choose depends on your project needs and location. An engine's power, mobility, and emissions determine how well the saw can meet your needs while keeping employees safe.

Gas

Gas-powered concrete saws deliver the most power, so they're an excellent choice for your larger jobs. A gas-powered saw's internal combustion engine enables it to run longer and faster than electric and battery-powered models. You cannot use a gas-powered saw for indoor applications because the gas produces fumes during operation, but it's a great option for your outdoor jobs.

Diesel

Like gas-powered concrete saws, diesel-powered models offer excellent power ideal for large jobs. A diesel-powered saw also delivers more torque than other models, helping it hold the blade at higher revolutions per minute.

Electric

An electric concrete saw requires an outlet to operate and is slightly less powerful than a gas-powered saw, but it's an excellent option for indoor applications. You can use an extension cord to increase your electric-powered saw's reach and mobility.

Battery-Powered

How to Install a Blade

Proper blade installation may differ slightly according to a saw's specific manufacturer's instructions. However, safe blade installation typically requires the following steps:

- Remove the blade cover and arbor cap.

- Inspect the blade and arbor for flatness, under-cutting, segment damage, and core fatigue.

- Place the blade on the arbor shaft.

- Place the nut over the blade.

- Place the blade cover back on the saw.

- Ensure the water tank hose is connected.

- Tighten the belt if necessary.

- Ensure the arbor shaft's bearings are lubricated.

Concrete Saw Safety

Safety is crucial when using all types of concrete saws. Proper maintenance, operation, and precautions prevent accidents and injuries and help your company comply with regulations. Protect yourself and your employees with the following safety guidelines:

Protect Your Lungs

Cutting hard materials with a concrete saw can generate harmful dust, such as respirable crystalline silica. Inhaling small silica particles can cause irreversible lung damage and diseases.

Safe concrete saw operation is crucial for preventing serious health complications. You can protect your lungs with the following safety tips and guidelines:

- Use wet cutting when possible: Wet cutting directs a continuous water stream onto your concrete saw blade to wet the material you cut. This method reduces the amount of silica dust you generate while operating the saw.

- Implement the wet-cutting method properly: Carrying out your operations according to the saw manufacturer's instructions helps minimize dust emissions. Before operation, ensure the saw's hoses are damage-free and connected securely to the saw. You should also adjust the hose nozzles so water reaches the blade. Also, inspect the blade for wear and maintain the saw's dust-control features according to your manufacturer's manual.

- Clean your work area after operating the saw: Cleaning the slurry your saw produces after you complete cutting prevents it from drying and releasing dust into the air you breathe. This is an essential step of wet or dry cutting because it protects anyone who enters the jobsite after you complete the task.

- Use extra ventilation when cutting indoors: Indoor dust exposure can still be high even when you use the wet-cutting method. Extra ventilation is essential for enclosed areas and indoor cutting because it reduces the amount of dust that enters and circulates within an area. You can increase ventilation with solutions such as air ducts, portable exhaust fans, and exhaust trunks.

- Maintain airflow: It's also crucial to ensure employees do not impede ventilation or airflow. Position ventilation equipment so it directs contaminated air away from workers. Also, keep doors and windows open when necessary.

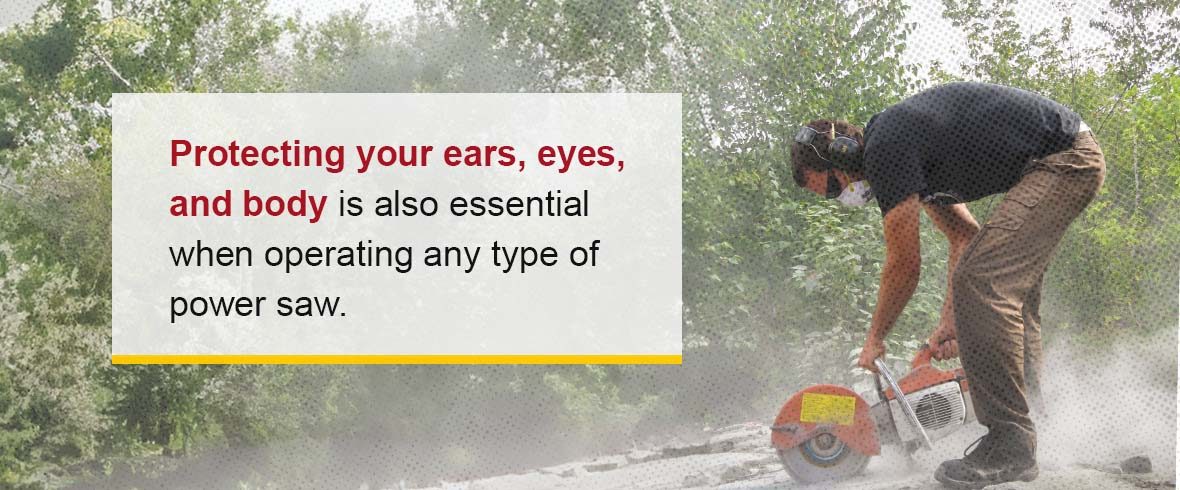

Wear Personal Protective Equipment

Protecting your ears, eyes, and body is also essential when operating any type of power saw. You should always provide or wear the following PPE for safe concrete saw operation:

- Fitted clothing

- Safety shoes

- Hearing protection

- Safety glasses

- Hard hat

- Face shield

Use Safe Positioning and Operational Practices

Practice the following safe positioning tips to avoid accidents and injuries when operating a concrete saw:

- Always hold a concrete saw firmly, using both hands to grip the equipment and keep it steady.

- Maintain strong footing and good balance.

- Avoid bending over a saw blade or standing directly behind it.

- Always hold the saw at the shoulder line or below to avoid overreaching.

- Only use a concrete saw for the materials it's designed to cut.

- Avoid using an abrasive blade on inappropriate materials.

- Use alternative equipment or tools to remove debris or pry objects out of cutting spaces.

- Repair a saw before use if it's damaged or wobbly.

- Keep the saw's guard in the proper position and avoid pulling it past its stopping point.

- Decrease pressure on the saw as you near the end of a cut to maintain control if it strikes an object.

- Align your blade with each cut before gently re-entering it to prevent the blade from binding.

- Never twist a saw blade at an angle.

- Support and secure objects before cutting them.

Establish Safe Work Zones

Keep concrete saw operators and nearby employees safe with established work zones. Establishing exclusion zones prevents surrounding employees from entering a high-risk area while an operator uses a concrete saw. Implement the appropriate signage and physical barriers to prevent accidents.

Train Each Employee Thoroughly

Proper training ensures employees understand how to operate a concrete saw and maintain safety. You should provide thorough training for any employee who operates a saw or works in an area surrounding saw usage.

While general safety tips such as wearing PPE and maintaining proper balance apply to all concrete saw types, you must also consider specific safety guidelines for each saw your team operates. Each model comes with specific manufacturer's instructions and guidelines; it's essential to update training each time you rent or add a new saw to your fleet.

High-Performance Concrete Saws From The Cat® Rental Store

The Cat® Rental Store offers a wide selection of durable, high-performance concrete saws. You can rent the following concrete saws to enhance jobsite efficiency, safety, and convenience:

- Handheld cut-off concrete saws: The Cat Rental Store connects with industry leaders to provide highly efficient and easy-to-transport handheld cut-off concrete saws.

- Tile saws: The Cat Rental Store's selection of tile saws enables you to make smooth, uniform cuts for optimal accuracy.

- Walk-behind concrete saws: You can rent a powerful walk-behind concrete saw, allowing you to work with heavy concrete, trench, perform asphalt work, and complete patch repairs.

Rent High-Quality Concrete Saws Today

Concrete saws deliver the power and precision to make smooth, clean cuts in hard materials such as concrete, asphalt, tile, brick, stone, and metal. We offer concrete saws from the industry's top manufacturers so you can diversify your capabilities or try top-performing models before you buy. Find The Cat Rental Store near you to locate the right equipment for your next job.

Find The Cat Rental Store Near You