Construction Equipment Management: The Complete Guide

Construction equipment is one of the most valuable assets in your business. Managing it effectively can save money, extend machine life, and keep projects on schedule. This complete guide explains construction equipment management in detail—what it is, why it matters, and how to implement strategies that improve efficiency and reduce costs. You’ll also learn how renting equipment from The Cat® Rental Store can support your management plan.

What Is Construction Equipment Management?

Construction equipment management is the practice of tracking, evaluating, and optimizing your fleet. It covers everything from storage and maintenance to financial planning and rental decisions. Good management helps you balance costs with usage, avoid breakdowns, and make smart buy-or-rent choices.

At its core, equipment management answers these questions:

- How much is each machine costing us?

- Are machines being used efficiently or sitting idle?

- Should we rent, buy, or sell equipment?

- Are operators using machines safely and correctly?

Why Construction Equipment Management Matters

Strong equipment management practices deliver measurable benefits, including:

- Lower ownership and operating costs

- Longer equipment life span

- Fewer breakdowns and delays

- Better safety for operators and crews

- Improved project scheduling and profitability

- Easier decisions on renting vs. buying

Best Practices for Construction Equipment Management

Here are proven strategies to improve the way you manage your fleet.

1. Store Equipment Properly

Poor storage shortens equipment life. Moisture, dust, and exposure to the elements can cause rust, contamination, and part failures. Whenever possible, store machines indoors. If that’s not an option, use protective covers designed for outdoor equipment storage.

Also store fuel and coolants in clean, sealed containers. Contamination in liquids can damage engines and reduce machine reliability. Proper storage protects your investment and increases resale value.

2. Create Rules and Guidelines

Rules ensure operators handle equipment safely and correctly. Create guidelines based on manufacturer manuals, safety recommendations, and dealer advice. Cover areas such as proper usage, preventive maintenance schedules, and storage procedures.

Communicate these rules clearly to all staff. Consistency reduces misuse, lowers accident risks, and helps machines run more efficiently.

3. Monitor Equipment Condition

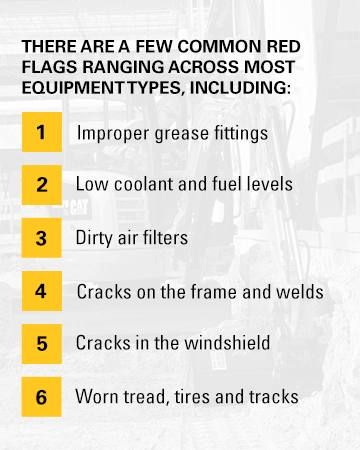

Regular inspections prevent small problems from becoming major failures. Check for issues like:

- Low coolant or fuel levels

- Dirty filters

- Worn tires or tracks

- Cracks in frames or welds

- Damaged windshields

- Missing or loose parts

Daily monitoring logs create accountability and make it easier to schedule repairs before breakdowns occur.

4. Use Dealer Assistance

Dealers have the expertise and resources to perform high-quality repairs. Working with a Cat dealer ensures you get genuine parts and expert service. This reduces the risk of improper repairs that lead to bigger costs later.

Dealer support also makes budgeting easier since service costs are more predictable compared to third-party repairs.

5. Schedule Preventive Maintenance

Preventive maintenance is critical for long-term performance. Schedule routine tasks such as:

- Oil and filter changes

- Brake replacements

- Hydraulic fluid checks

- Tire pressure inspections

- Track or tread replacements

Follow manufacturer recommendations but adjust for harsh environments. For example, dusty conditions may require more frequent air filter changes.

6. Use Downtime Wisely

Downtime doesn’t have to mean wasted time. Use it for:

- Extra inspections and cleaning

- Operator training and certification

- Preparing equipment for the next job

- Ordering replacement parts or attachments

- Catching up on paperwork and fleet records

7. Improve Communication

Operators are usually the first to notice issues. Make it easy for them to report problems to management. Set up clear communication channels for damage reports, financial concerns, and scheduling delays.

Quick communication allows for faster repairs, reduced downtime, and fewer surprise costs like overtime pay.

8. Track Capacity and Compatibility

Every machine has load limits and compatible attachments. Overloading equipment or using incompatible parts can lead to damage, safety hazards, and costly delays. Always follow manufacturer guidelines to ensure safe and efficient operations.

Key Questions to Ask in Construction Equipment Management

Asking the right questions helps managers evaluate fleets and prepare for future projects. Consider questions such as:

- Do we have the equipment we need for upcoming jobs?

- Should we rent instead of buy for specific projects?

- What are the real costs of operating and transporting our machines?

- How can we maximize efficiency with fewer machines?

- What preventive maintenance should be scheduled right now?

Why Renting Is Part of Equipment Management

Renting construction equipment is often the smarter choice, especially for specialized or short-term projects. It lowers costs, reduces risks, and gives you access to the latest technology without long-term commitments.

Other benefits of renting include flexibility to meet demand across multiple projects and access to a wider range of models and attachments

FAQs About Construction Equipment Management

What is construction equipment management?

It’s the practice of evaluating, maintaining, and tracking your fleet to reduce costs and improve performance.

What is the role of preventive maintenance?

It helps avoid breakdowns, extend machine life, and keep projects on schedule.

Partner With The Cat® Rental Store

The Cat Rental Store supports your construction equipment management strategy with a wide range of late-model machines and attachments. We provide flexible terms, reliable maintenance, and expert dealer support so you can keep your fleet efficient and productive.

Browse our rental equipment inventory, request a quote or find your local dealer to learn more.