Embracing Digitalization in Construction

As vital as construction is for modernizing infrastructure, the industry tends to lag. Construction has lower rates of digitalization than almost any other industry, despite the many benefits it has to offer. From efficiency-boosting software platforms to high-tech virtual models and monitoring devices, digital tech can speed up projects, improve safety and do much more.

When staying competitive and bringing the industry into the 21st century, digitalization is inevitable and comes with a range of benefits. Let's look at these innovative trends and how digitalization helps the construction industry.

Jump to a section:

The State of Digitization in the Construction Industry

Digitization hasn't always been a significant focus, but it's picked up speed in recent years. Almost two-thirds of respondents to a McKinsey survey expect industry transformation to accelerate. More than half of them are investing more to adapt to the future. Across industries, the world has leaped into digital transformation, taking advantage of its many benefits.

The construction industry often faces high risk and low profits. Companies spend a lot of time optimizing costs by working more efficiently, improving equipment lifespans, creating safer workplaces and making other smart moves. Digital tools can help in many ways, including benefits like these.

- Lower costs: Most of the digital tools we'll be discussing aim to reduce expenses somehow, perhaps through automated calculations, more efficient management, fewer safety problems or better performance in other areas of operations. Digital tools often reduce costs in less direct methods, too. For example, they might contribute to fewer disciplinary actions and fines from authorities by increasing the reporting reliability.

- A competitive edge: Consumers have no shortage of digital tools, and they often equate them with professionalism and modernity. Many people use texts, emails, instant messages and other forms of communication all day, so having to make a phone call to their contractor might seem archaic. Other high-tech options, like virtual walk-throughs or monthly reports, can be significant selling points when choosing one company over another.

- More reliability: Hiccups are inevitable in construction, but if your projects are full of them, there may be room for improvement. Digitalization can help avoid and mitigate build issues, monitor equipment and collect data. A more reliable project can help you avoid unexpected downtime and retain a robust reputation for dependable service.

- Speed: Digitalization can also improve the speed of many different construction tasks. Designers, engineers, contractors and clients can communicate from anywhere, and contractors can monitor various aspects of a job site to ensure it runs smoothly and according to schedule. Automation can also eliminate some tasks.

- Protected investments: A construction company invests in many different assets, like equipment and labor. Digitalization can help you maximize value from these assets. For instance, sensors and algorithms can monitor equipment and provide maintenance predictions to extend the equipment's lifespan, while safety tools can help protect your employees and avoid costly workplace incidents.

- Better reporting: Construction requires plenty of reporting and documentation. Digital platforms can help you capture, store, report and share your work. Whether you need to take photos, generate budgets or submit information to an authority, a digitized company will have a much easier time than one without these tech tools.

Digital Construction Innovations

Whether they've been around for years or are still under development, you'll find many types of digital tools in construction.

1. Software

Here's one you probably expected. Construction software can run the gamut, from administrative tasks to on-the-job tools. You might find stand-alone tools, but they typically come bundled in construction management software. Many of these platforms are cloud-based, so you can access them from anywhere you can use the internet. For instance, contractors can log into their software from a cellular-connected tablet in the middle of the job site and make updates without needing to drive back to the office.

Gone are the days of transporting reports between the office and the job site to share with other team members. With the help of cloud-based software and other essential wireless technologies like Bluetooth and cellular networks, contractors and employees can access their digital tools from anywhere, provided they have a device like a tablet, phone or laptop. Partners can see updates immediately, and team members can quickly and reliably communicate.

Some aspects of the job you can digitize include:

- Estimating

- Project scheduling

- Project management

- Accounting

- Customer relationship management

- Asset management

- Machine monitoring

- Payroll

Many of these tools enable automation for tasks like budgeting and generating estimates. Some platforms even leverage machine learning and artificial intelligence. They can offer advanced predictions and forecasts based on the unique landscape of your business and the industry.

2. Building Information Modeling

Building information modeling is a significant development in construction. The market has skyrocketed in the last decade and currently has a compound annual growth rate of slightly over 11%. Several governments, like the United Kingdom and Singapore, have even started to require BIM for some projects.

With a BIM platform, everyone involved in the process — engineers, architects, contractors and anyone else who has a hand in the project — can work with a virtual 3D model of a structure. BIM platforms incorporate a vast array of data. Each component in the model has data attached to it, such as measurements, materials, financial details and procurement information. They add value at every stage, from conception to build. A BIM can offer valuable information even after the project concludes, such as data needed for renovations.

With this centralized platform, everyone working on the project can view each other's changes and see their responsibilities in context with everyone else's. They can see how other teams' work will affect specific parts of the building. For instance, if an adjustment to a room's structure affects the ductwork, the HVAC system might need alterations, too. With the platform's collaborative nature, these different teams stay in the loop.

A BIM platform's capabilities can vary widely, and there are six levels based on the amount or type of information they handle.

- Level 0: Level 0 BIM is the starting point and generally refers to no collaboration at all. Paper printouts or drawings would be an example of Level 0.

- Level 1: A Level 1 BIM may incorporate some 3D modeling through computer-aided design, but primarily uses 2D drawings for production and documentation. This level doesn't usually have much collaboration.

- Level 2: Level 2 BIM almost entirely uses 3D models, but different teams might work separately and don't necessarily collaborate. Still, these platforms use a shared file format, and stakeholders can more easily exchange information.

- Level 3: At Level 3, various teams use the same 3D models and collaborate more. It's more centralized and can identify clashes between different components.

- Level 4: Level 4 adds scheduling data to the mix.

- Level 5: With Level 5, you can incorporate more financial information, such as budget analysis and estimations.

- Level 6: Lastly, Level 6 adds information about the building's energy use and can support more sustainable building practices.

BIM is an excellent way to identify problems before work even begins and optimize construction processes overall. It can also appeal to clients by helping them visualize the space.

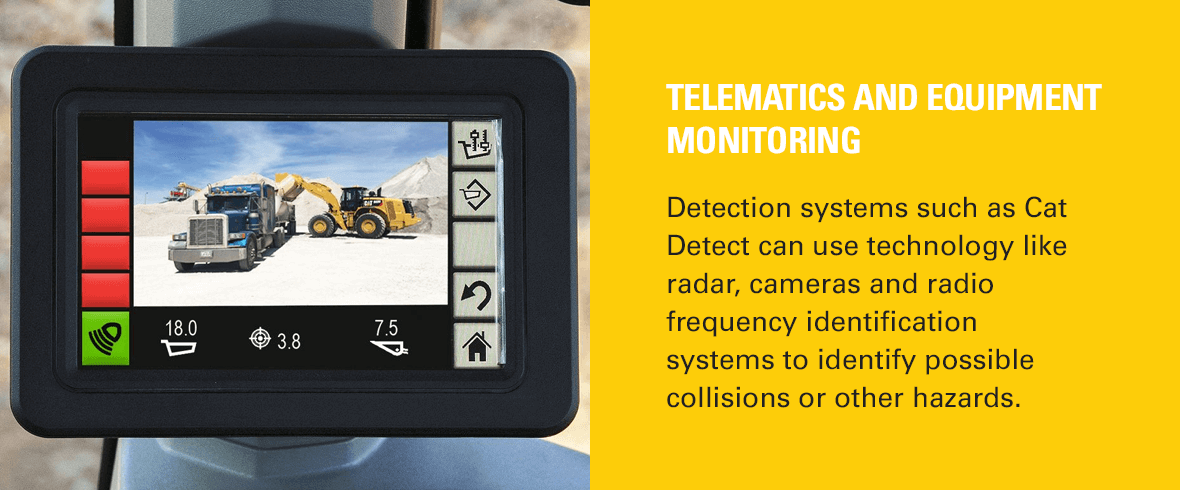

3. Telematics and Equipment Monitoring

Though telematics has been around for a while, it still has a lot to offer and keeps pace with new technological innovations. Telematics systems send and receive data, connecting heavy equipment to a larger platform. As you can imagine, this covers a range of purposes, from collecting basic information about use hours and maintenance requirements to sending alerts when drivers show signs of fatigue or stopping the machine before a collision.

A construction company that goes all-in on telematics might find themselves gathering information to improve productivity, maintenance practices, safety and much more.

Here are some of the tasks you can do with telematics.

- GPS tracking: Telematics can keep an eye on your equipment at all times. A contractor might receive an anti-theft alert if a machine moves from a geofenced job site, or track movements within the job site to gain insights on usage. You may even save on insurance premiums if you have tracking systems in place.

- Monitoring equipment use: You can also use telematics to monitor equipment use over time. You can see if it's been sitting idle and how much fuel you're using. Aside from helping you meet your productivity goals, you can use these records to save on fuel tax refunds, which depend on whether you use the equipment on- or off-road.

- Monitoring maintenance needs: Maintenance needs often vary by usage, which telematics can track. It can help you gauge maintenance needs, inform a predictive maintenance algorithm or send you alerts about needed tasks. Combine telematics with machine learning predictions, and you'll have an excellent maintenance solution on your hands.

- Monitoring driving behavior: Telematics can also help you identify problematic driving behavior, such as speeding or erratic movements. Some systems can even watch the operator's face for signs of fatigue or distraction that could create a safety hazard and shut down the equipment if needed.

- Detecting objects and potential hazards: Detection systems such as Cat® Detect can use technology like radar, cameras and radio frequency identification systems to identify possible collisions or other hazards. They might notify the operator or stop the machine to prevent incidents.

- Assessing payloads: Operators can improve efficiency and keep track of their loads with smarter payload tools. For example, Cat Payload can weigh loads on the go, offer data in a scoreboard display and provide reports on key performance indicators.

Embracing digitalization in construction opens up many possibilities for equipment. You can even remotely control it, but we'll talk about that more later.

4. Augmented and Virtual Reality

Augmented reality and virtual reality have made significant strides, and education and training are now some of the most prominent applications of this technology. It allows employees to experience the job at hand without putting themselves or others in danger.

Though the lines between the two technologies can blur, virtual reality generally refers to a completely digital setting, while augmented reality involves placing virtual elements over the real world. Both technologies have helped surgeons, pilots, engineers and many other professionals hone their skills in low-risk environments.

With a pair of goggles and a VR setup, a construction trainee can sit "behind the wheel" of a massive crane and learn to operate it from the safety of an office chair rather than on a job site with valuable resources and personnel nearby. A client can explore the building virtually and make decisions or changes sooner while visualizing the completed project more accurately.

Augmented reality can also help bring plans to life. A contractor can put on a set of goggles or hold up a tablet in front of the job site and see a 3D rendering of the building superimposed on the empty space. They could conduct a virtual walk-through or see notes and measurements in context with the structure in front of them.

AR and VR can improve collaboration across faraway locations and even enhance safety on the job sites. A heads-up display might present a safety warning for a worker entering a hazardous area, or provide more context or instructions for the task at hand. The potential uses for AR and VR are wide-reaching and will likely continue to evolve.

5. Smart Personal Protective Equipment

Construction workers have some of the most dangerous jobs, so anything you can do to create a safer environment is welcome and necessary. One of the benefits of digitalization in construction is the improved monitoring and safety capabilities it has to offer. Personal protective equipment covers an array of items that protect the wearer, like hard hats, high-visibility vests and noise-blocking earmuffs. By combining traditional PPE with digital capabilities, you unlock a world of safety benefits.

Here are some examples of smart safety equipment.

- Clothing sensors: Sensors integrated with or attached to a worker's clothing or vest can look for hazards like gas, chemicals and excessive heat. They might send alerts to the worker to stay cautious or take a hydration break, and the sensors can alert supervisors to intervene if necessary.

- Helmets and eyewear: Smart helmets can detect impacts, falls, shocks and even fatigue. A helmet could automatically notify supervisors and nearby workers to assist if needed, and GPS tracking can help medical support find the worker faster. Alongside eye protection, smart glasses might offer notifications about nearby hazards, show protocols during a task or display information so the wearer can monitor changing conditions without taking their eyes off the work in front of them.

- Gloves: Near-field communication adds smart capabilities to gloves, too. A chip inside a pair of gloves might prevent a worker from operating equipment or entering an area without the appropriate PPE or clearance.

- Hearing protection: Smart hearing protection devices can adapt to changing surroundings for optimal safety and communication. Even if the user removes their earmuffs, such as placing them around their neck, a smart device might vibrate or flash when the noise starts up again to remind them to put the earmuffs back on.

- Activity trackers: Activity trackers, such as rugged smartwatches, can monitor construction workers and make sure they don't overexert themselves, which is especially vital with intense physical labor and heat. If these watches pick up on distress or a fall, they can signal supervisors, nearby workers and medical response teams. Wearables can aid in hands-free communication, too.

Besides boosting safety, these devices can improve communication and oversight. Location tracking allows supervisors to see where their employees are and make decisions accordingly. Some smart PPE, such as helmets or activity trackers, can also incorporate communication devices like radios or phone calls.

6. Robotics and Remote Control

Many types of equipment are becoming more autonomous or allowing for remote control. You can control large or complex equipment from a remote control center or even on-site. Remote controls like those from Cat Command can add efficiency and safety, allowing an operator to manage multiple machines from a comfortable location away from job site hazards. A remote control system can also improve safety on the job site by keeping operators out of hazardous locations or conditions.

Autonomously running your equipment is also possible. With the help of modern-day sensors and data about the job site, you can set many types of equipment to work with automated processes.

Drones are another exciting area of development in construction. They can zip over a site and collect data that would take hours for a human to gather. They can also collect data from dangerous or hard-to-access areas. Drones, or unmanned aerial vehicles, can conduct many preplanning tasks, improve safety and monitor progress. Some drones are also capable of more advanced imaging, like laser scanning and thermal imaging, for more comprehensive results.

Along with these benefits for operations, drones can help with marketing. They're ideal for obtaining promotional images and providing regular updates to the client. You can even give them a live fly-through tour to see a bird's-eye view of the project without setting foot on the site.

7. 3D Printing

Many fields that demand precision have embraced 3D printing. Construction can benefit from it, too. While 3D printing can produce entire buildings, a more common approach is to use it for individual components. Paired with the industry's existing familiarity with CAD and BIM, 3D printing is a straightforward integration for many construction companies.

By 3D printing parts, construction businesses can reap benefits like these.

- Custom parts: Many applications call for custom parts. They might make a particular feature possible, improve performance or reduce costs compared to off-the-shelf solutions.

- Speed: Having custom components made takes time — connecting with the manufacturer, communicating designs, waiting for the build, etc. With a 3D printer, contractors can print precise, custom components as needed in comparatively little time, so they're ready to keep the project on schedule.

- Reduced waste: Built-to-order parts can help reduce waste, and you can often recycle scraps or unused materials.

In addition to building components, 3D printing can help create accurate small-scale models, excellent for visualizing the project and sharing the vision with clients.

Embracing Digitalization in Construction With The Cat® Rental Store

Caterpillar is an industry leader in digitalization. Whether you're ready to dive into these digital solutions or want to test the waters, The Cat Rental Store can help. We have a vast inventory of Cat machinery equipped with modern technology for telematics, remote control, fleet management and more. We can help you implement these scalable solutions or try them out with a rental. You can see firsthand how digitalization helps construction by incorporating it into your fleet.

Find a dealer near you or call 1-800-RENT-CAT to discuss digitalization options and see available equipment.

Find The Cat Rental Store Near You