14 Essential Construction Attachments

Attachments make it possible to get more value from the machines you already own. A skid steer or mini excavator can switch between multiple tools in a single day, turning into a loader, digger, cutter, or compactor with the right attachment. For contractors, landscapers and demolition crews, attachments provide flexibility and efficiency. All without requiring investment in specialized standalone machines. Here’s a deep dive into 14 of the most useful construction attachments, organized by category, along with real-world examples of how they’re used.

Digging and Groundwork Attachments

Groundwork is the foundation of most construction projects. These attachments help crews dig holes, cut trenches and prepare soil with accuracy.

- Augers: These are used for drilling consistent holes in soil for posts, piers, or trees. Fence installers save hours compared to manual digging. Direct-drive augers provide speed for sandy soils, while gear-driven augers deliver torque for rocky terrain.

- Trenchers: Cut narrow, straight trenches for utilities like water lines or electrical conduits. Municipal crews rely on trenchers for fast roadside repairs where larger equipment won’t fit.

- Backhoe attachments: Turn a skid steer into a versatile digger for foundations, utility lines, or grading. They’re popular on smaller sites where a full-size excavator isn’t practical.

- Tillers: Break up compact soil and mix in compost, making them valuable for landscaping. Farmers use tillers to prepare seedbeds and incorporate fertilizer before planting.

Clearing and Material Handling Attachments

From storm cleanup to warehouse work, handling materials efficiently is critical. These attachments make lifting, carrying and clearing easier.

Grapple buckets: Equipped with hydraulic clamps, they secure awkward loads like logs and scrap metal. Root grapples pull stumps; scrap grapples are standard in recycling yards.

Rakes: Level uneven ground, collect debris and break up clumps. Landscapers use them to prepare lawns, while contractors clear sites quickly before grading.

Hydraulic pallet forks: These provide reliable pallet handling. On construction sites, forks move materials like drywall or lumber; in agriculture they handle hay bales and seed totes.

Brushcutters: Clear thick vegetation and small trees. Crews use them to reclaim overgrown lots or cut back roadside brush safely and efficiently.

Demolition and Recycling Attachments

Demolition sites demand power and precision. These attachments make it possible to break apart structures, recycle materials and reduce hauling costs.

Hydraulic breakers: Use force to fracture concrete, asphalt, or rock. Road crews use breakers for pavement repair, while mining operations deploy them for breaking large boulders.

Multi-processors: Feature jaws that rotate 360 degrees for cutting steel or crushing concrete. They help reduce how often the machine needs to be repositioned. This saves time in structural demolition.

Shears: Hydraulic shears cut through steel beams, rebar and scrap metal. Rotating shears maximize productivity by reducing machine movement on demolition sites.

Pulverizers: Break concrete into smaller pieces while separating rebar for recycling. Contractors reuse crushed concrete as fill material, lowering project costs.

Grading and Surface Preparation Attachments

Once digging and demolition are complete, surfaces need to be smoothed and stabilized. These attachments prepare sites for final work like paving or construction.

Blades: Push and grade material efficiently. Contractors use S-blades for small backfilling tasks, while U-blades move large volumes of soil or aggregate. Cushion blades withstand abrasive conditions in landfill or mining applications.

Compactor attachments: Compress soil, gravel, or asphalt. Plate compactors handle trench backfilling. Drum compactors finish road surfaces. Wheel compactors provide smooth coverage for utility work.

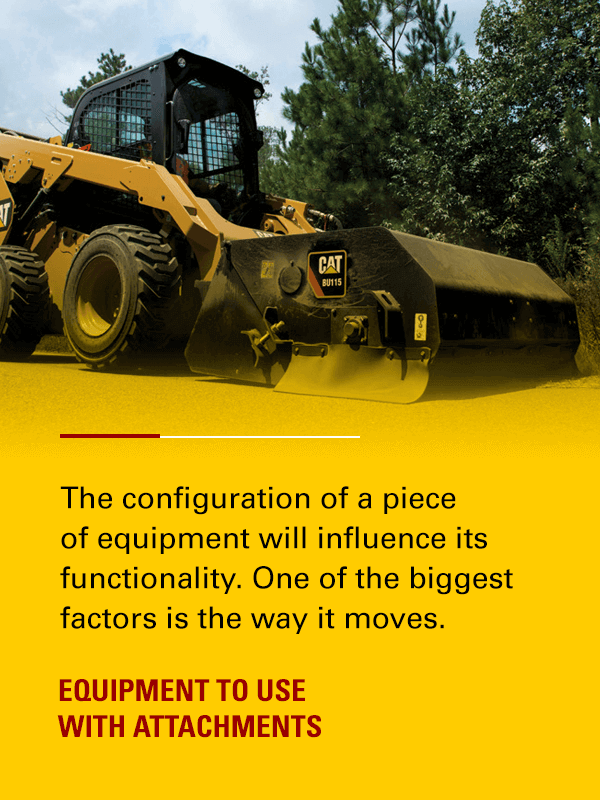

Which Machines Work With These Attachments?

Skid steers, excavators, backhoe loaders and wheel loaders are common carriers for attachments. Couplers make tool changes quick and easy.

Tracked models excel in mud, sand, or snow, while wheeled versions protect grass and pavement. Radial-lift skid steers are suited for digging, while vertical-lift versions excel at loading into trucks.

Why Rent Construction Attachments?

Renting provides flexibility and cost control, especially for attachments needed only occasionally. Key benefits include:

- Lower upfront costs: Pay for attachments only when they’re needed, avoiding long-term investments.

- Operational flexibility: Expand service offerings with seasonal tools like snow blades or forestry cutters.

- Hands-on testing: Try attachments before committing to purchase to ensure they meet your project needs.

The Cat® Rental Store gives contractors access to attachments maintained and ready for work. Explore our inventory of attachment rentals to view available options or find a dealer near you for local support. Find the Cat Rental Store near you to connect with a dealer today.

Find The Cat Rental Store Near You