Construction Industry News

Featured Post

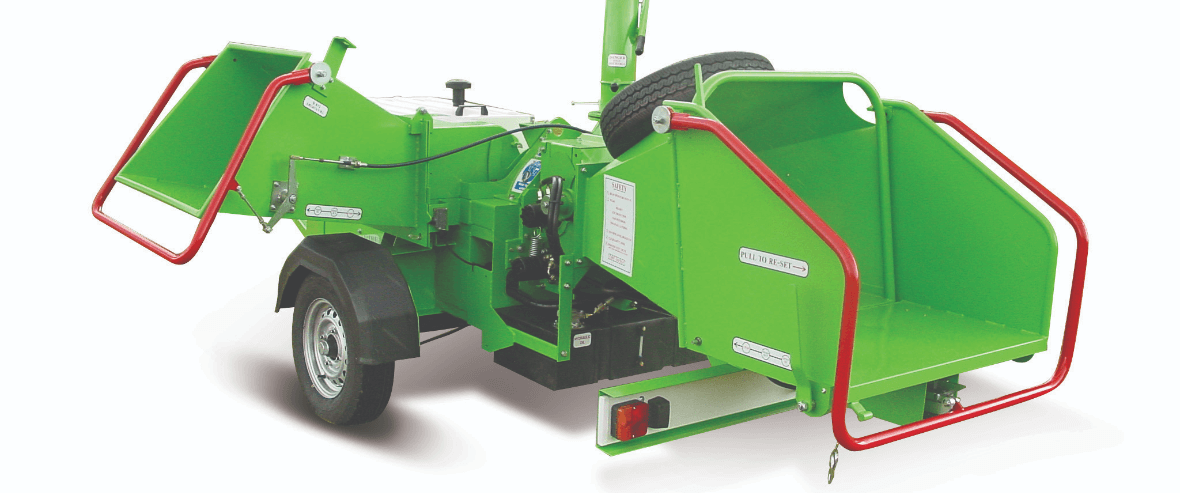

What to Know About Renting a Mulcher

There are many types of loaders available. Read on to learn more about the different loaders and their benefits!

Read MoreAt The Cat® Rental Store, our trained experts are here to help you succeed. Read through our rental guides below to learn more about questions you have about renting, industry applications, machine productivity and more.

-

What To Know About Airport Construction Equipment Rentals

See how road wideners, asphalt pavers, and monitoring tech support airport construction. Plan your fleet and learn where to rent equipment near you.

Read More[Construction, lead gen, Safety, existing customer, sales qualified lead, marketing qualified prospect, Cat Rental] -

Stump Grinder Rental FAQs: What To Know Before You Rent

Learn how stump grinders work, types, safety basics, when not to grind, and what to do with chips. See models and where to rent near you from The Cat® Rental Store.

Read More[Construction, lead gen, existing customer, sales qualified lead, marketing qualified prospect, Cat Rental] -

Is Your Construction Project Taking Too Long?

If your schedule is slipping, tighten permits and planning, add capacity with construction equipment rentals, right‑size machines, train operators, and improve communication to recover time.

Read More[Construction, lead gen, existing customer, sales qualified lead, marketing qualified prospect, Cat Rental] -

Commercial Flooring Maintenance Using Rental Equipment

Learn the best way to handle commercial flooring maintenance using sweepers, floor scrubbers, and sweeper scrubbers. Compare walk-behind and ride-on and see how to rent the right machine.

Read More[Construction, Commercial, lead gen, existing customer, sales qualified lead, marketing qualified prospect, Cat Rental] -

Keep Your Jobsite Productive with Winter Construction Equipment

Prepare crews and sites for cold weather with heaters, trailers, snow attachments, ground thaw, light towers, and reliable power. See why renting helps you stay on schedule.

Read More[Construction, lead gen, existing customer, Snow and Ice, sales qualified lead, marketing qualified prospect, Cat Rental] -

Best Snow Removal Attachments To Rent

See the six best snow attachments and how to choose by project, site, machine, and conditions. Compare brooms, buckets, blades, pushes, plows, and blowers, then rent with confidence.

Read More[Construction, lead gen, existing customer, Snow and Ice, sales qualified lead, marketing qualified prospect, Consideration] -

6 Steps to Improve Construction Company Profitability

Use six practical steps to increase construction profitability—productivity, cost control, estimating, goals, communication, and post-project reviews—plus how rentals and Cat technology help.

Read More[Construction, Construction, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Rent Equipment for Short‑Term Jobs | Fast Local Support

Book the right rental equipment for short‑term jobs. See how to choose machines and attachments, control cost and risk, and reserve near you with The Cat® Rental Store.

Read More[Construction, Awareness, existing customer, Rental, sales qualified lead, marketing qualified prospect, Consideration] -

Planning for Your Equipment Needs

Learn how to plan equipment for upcoming jobs. Make a list, set a budget, handle maintenance, and rent what you’re missing from The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Light Compactors: Types, Uses, And How To Choose

Learn light compactor basics, compaction forces, soil and project fit, operating tips, and how to choose. See brands and where to rent near you from The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

What Is a Shear Wall in Construction?

Learn what shear walls are, how they work, and which buildings need them. Rent equipment from The Cat® Rental Store to support shear wall construction.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Portable vs Stationary Air Compressor Rental

Compare portable vs stationary air compressors. Learn benefits, uses, and rental options from The Cat® Rental Store for construction, manufacturing, and more.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

10 Tips to Increase Jobsite Efficiency

Improve jobsite efficiency with 10 practical tips across planning, goals, data, technology, training, communication, and equipment. Plus, see rental options from The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Proper Concrete Practices: Mix, Set, Cure

Learn concrete best practices for mixing, setting, and curing, plus what can go wrong if you skip steps. Plan projects with The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Measuring And Monitoring Equipment Efficiency: A Practical Guide

Learn how to measure and monitor equipment efficiency, which factors matter, the metrics to track, and tools that help. See how rentals support uptime and cost control.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Steel vs. Aluminum Trench Boxes: Which to Rent?

Compare steel vs. aluminum trench boxes. Learn durability, weight, applications, and rental benefits with The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Scissor Lifts vs. Scaffolding: Which Is Safer and Smarter?

Compare scissor lifts vs. scaffolding for working at heights. Learn the benefits, safety advantages, and rental options from The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

9 Aerial Lift Safety Tips for Every Jobsite

Stay safe when working at heights with these 9 aerial lift safety tips. Learn how to prevent hazards and rent safe, reliable lifts from The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Construction Project Management: A Practical Guide

Learn the construction project management basics: roles, tasks, stages, methods, and common challenges along with helpful links and rental options from The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Choosing the Right Aerial Lift Rental for Holiday Decorating

Compare boom lifts, scissor lifts, and telehandlers for holiday decorating. Learn safety tips and rental options from The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Municipality, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

5 Essential Road Construction Machines to Rent

Discover the top 5 machines for road construction: graders, pavers, compactors, loaders, and excavators. Rent reliable equipment from The Cat® Rental Store.

Read More[Paving, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Trench Backfilling Tips for Safety and Efficiency

Learn how to backfill trenches using the right methods, materials, and equipment. Get tips on using loaders and rent reliable equipment from The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Choosing the Right Skid Steer Rental for Your Operation

Compare skid steer loader sizes, lifts, and features. Learn how Cat® skid steers and attachments can boost your operation with flexible rentals.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Benefits of Using Dehumidifiers in Construction

Discover how construction dehumidifier rentals improve results, protect materials, and create safer jobsites. Get reliable units from The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Simple Generator Safety Tips for Jobsites

Follow these generator safety tips to prevent hazards on the jobsite. Rent reliable generators from The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Land Management Equipment Rentals: When to Choose Different Options

Discover the best machines and attachments to rent for land management, including loaders, dozers, excavators, and six must‑have work tools.

Read More[lead gen, existing customer, Logging, Cat Rental, Awareness, Forestry, Land Management, Landscaping, sales qualified lead, Forestry machinery, marketing qualified prospect, Consideration] -

How to Reduce Equipment Downtime and Maintenance Costs

Cut downtime and maintenance costs with planning, inspections, data, software, and The Cat® Rental Store rentals. See how to build a practical plan and keep work moving.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Wheel Loader vs. Compact Track Loader: Which to Rent?

Compare wheel loaders vs. compact track loaders. Learn key differences, best uses, and how The Cat® Rental Store can help you choose the right loader.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

How to Choose the Right Rammer Rental for Soil Compaction

Learn how to choose the right rammer rental for soil compaction. Compare 2-cycle, 4-cycle, and battery rammers and see options at The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Attachments for Forestry and Landscaping Work

Explore Cat® attachments for forestry and landscaping. Learn how renting blades, mulchers, augers, and more helps boost efficiency and reduce costs.

Read More[lead gen, Awareness, Forestry, Land Management, existing customer, Landscaping, sales qualified lead, Forestry machinery, marketing qualified prospect, Consideration, Cat Rental] -

Which Demolition Equipment Rentals Do You Need?

See the essential machines and attachments for demolition projects. Learn how The Cat Rental Store can supply skid steers, dozers, excavators, and more.

Read More[Construction, lead gen, Awareness, existing customer, Demolition and Recycling, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Simple Trench and Shoring Safety Tips

Learn easy trench safety tips and see how The Cat® Rental Store can help with trench safety rentals.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Winter Equipment Rental & Cold Weather Safety Tips

Learn how to stay safe in extreme cold. Get winter work safety tips, cold stress prevention, and winter equipment rental solutions from The Cat Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, Snow and Ice, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Complete Guide to Construction Bidding

Learn how construction bidding works, where to find opportunities, and how to prepare accurate bids. Support your bids with rentals from The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

How Does a Road Widener Rental Help?

Learn the benefits of using a road widener for faster, more precise road construction. Rent road wideners from The Cat® Rental Store today.

Read More[Paving, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Why Does Road Construction Take So Long?

Learn why road construction projects face delays, from planning to equipment issues, and how rentals can help keep projects on track.

Read More[Construction, Paving, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Pressure Washer Tips: The Right Washer for the Job

Learn how to choose a pressure washer by power source, pressure level, water temperature, and nozzle size. Get your pressure washer tips from The Cat® Rental Store.

Read More[lead gen, Municipality, Awareness, existing customer, Landscaping, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

How to Choose the Right Construction Equipment

To choose the right construction equipment for your job, use these 7 factors: scope, site, size, specialty tools, attachments, staffing, and service.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Best Material Handling Equipment Rentals For Your Needs

Compare material handling options and learn how to choose by material, environment, and price. See trucks, bulk systems, storage, conveyors, and how to rent near you.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Top Causes of Construction Cost Overruns

Learn the top causes of construction cost overruns and how to avoid them. Improve planning and efficiency with support from The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

What Is Industrial Construction?

Learn what industrial construction is, how it differs from commercial construction, and the heavy equipment you can rent from The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Boom Lift vs. Scissor Lift: Key Differences

Learn the differences between boom lifts and scissor lifts, when to use each, and how to rent the right aerial equipment from The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

What Is Bypass Construction and What Equipment Do You Need?

Learn what bypass construction is, its benefits and challenges, and the equipment needed for roadway projects. Rent roadwork equipment from The Cat® Rental Store.

Read More[Construction, Construction, Paving, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

How to Choose Dam Construction Equipment for Rental

Learn which heavy equipment is essential for dam construction projects, including excavators, loaders, and compactors. Rent from The Cat® Rental Store today.

Read More[Construction, Construction, Power Plants, lead gen, Power Plants, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Tips for Choosing the Right Compaction Equipment Rental

Learn how to choose the right compaction equipment for your soil and jobsite needs. Rent rollers, rammers, and plate compactors from The Cat® Rental Store.

Read More[Construction, Paving, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

What Does Construction Telematics Include?

Learn what telematics is, how it works, and its uses in construction. See how The Cat® Rental Store supports efficiency with reliable equipment rentals.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Your Guide to Renting Backhoes

Learn everything about backhoe rentals in this guide. Discover uses, benefits, attachments, and why renting is smarter for your projects with The Cat® Rental Store.

Read More[Construction, Paving, lead gen, Mining, existing customer, Utilities, Mining, Cat Rental, Agriculture, Construction, Awareness, sales qualified lead, marketing qualified prospect, Agriculture, Consideration] -

What Size Dump Truck Should I Rent?

Learn how to choose the right size dump truck rental for your job. Consider job type, truck body, and capacity. Get expert help at The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Benefits of Renting Compact Tractors

Discover the benefits of compact tractor rentals, including fuel efficiency, versatility, easy operation, and attachment compatibility. Rent from The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Access the Latest Technology with Construction Equipment Rentals

Learn how construction equipment rentals give you access to the latest technology. Discover benefits like efficiency, safety, and cost savings with The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Types of Construction Bucket Attachments

Learn about the different types of construction bucket attachments and how to choose the right one for your machine. Rent bucket attachments from The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Rental Equipment Delivery: The How and Why

Learn how rental equipment delivery saves time, reduces risk, and lowers costs. Explore 9 benefits of having equipment delivered to your jobsite with The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Tax Implications of Renting Farm Equipment

Learn about the tax implications of renting farm equipment, including deductions, credits, and reporting requirements. Get expert rental support from The Cat® Rental Store.

Read More[Agriculture, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Agriculture, Consideration, Cat Rental] -

12 Types of Rental Spring Cleanup Equipment

Get your property ready for spring with the right rental equipment. Learn about 12 types of spring cleanup equipment available from The Cat® Rental Store.

Read More[lead gen, Awareness, Waste, existing customer, sales qualified lead, Landfills, marketing qualified prospect, Consideration, Cat Rental] -

How to Choose the Right Stump Grinder Rental

Learn how to choose the best stump grinder rental for your project. Compare sizes, features, and types to match your job needs with The Cat® Rental Store.

Read More[lead gen, Awareness, Forestry, existing customer, Landscaping, sales qualified lead, Forestry machinery, marketing qualified prospect, Consideration, Cat Rental] -

The Different Types of Aerial Lifts Explained

Learn about the different types of aerial lifts, including scissor lifts, boom lifts, material lifts, and personnel lifts. Find rental options at The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

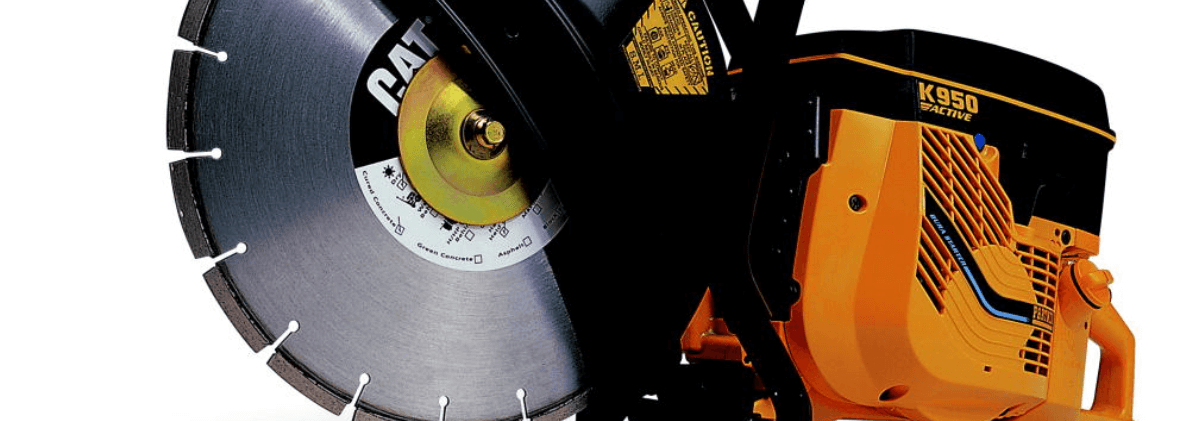

How to Choose the Right Handheld Cutoff Concrete Saw Rental

Learn how to choose the best handheld cutoff concrete saw rental. Compare battery, gas, and corded saws for different applications with The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Benefits of Renting Equipment with Grade Control

Renting equipment with grade control can save you time and money. Learn how Cat® Grade improves accuracy, efficiency, and safety on your jobsite.

Read More[Construction, Paving, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Benefits of Land Development Equipment Rentals

Discover the benefits of land development equipment rental, including flexibility, cost savings, and productivity. Learn how The Cat® Rental Store can support your projects.

Read More[Construction, Construction, lead gen, Awareness, Forestry, existing customer, ADIIND, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Best App For Managing Rental Construction Equipment

Discover how The Cat® Rental Store Customer Portal helps you manage construction equipment rentals. Learn about benefits, features, and time-saving tips.

Read More[Construction, Construction, lead gen, existing customer, sales qualified lead, marketing qualified prospect, Cat Rental] -

Forestry Mulching: Hire Out or Rent Mulching Equipment?

Compare whether to hire a forestry mulching company or rent mulching equipment and do it yourself. Learn about the benefits and your options from The Cat Rental Store.

Read More[lead gen, Awareness, Forestry, Land Management, existing customer, sales qualified lead, Forestry machinery, marketing qualified prospect, Consideration, Cat Rental] -

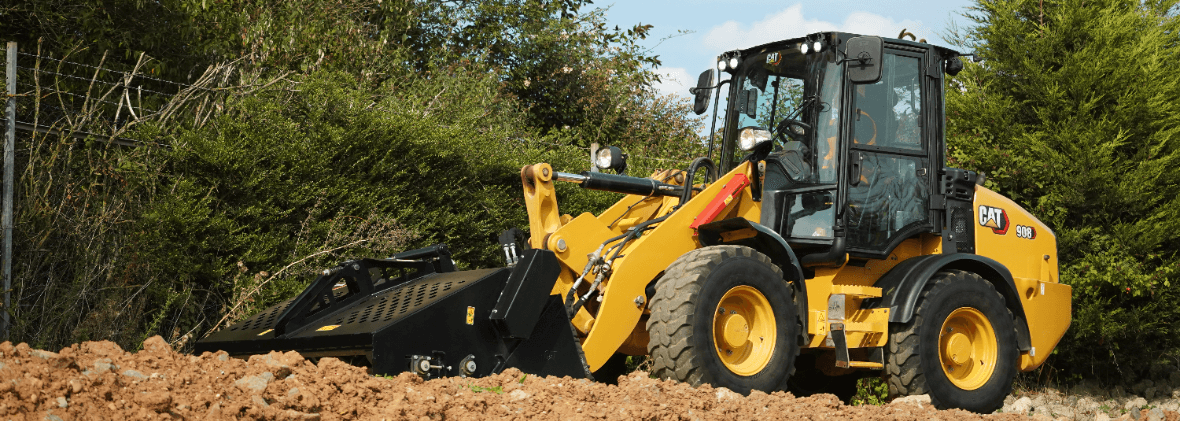

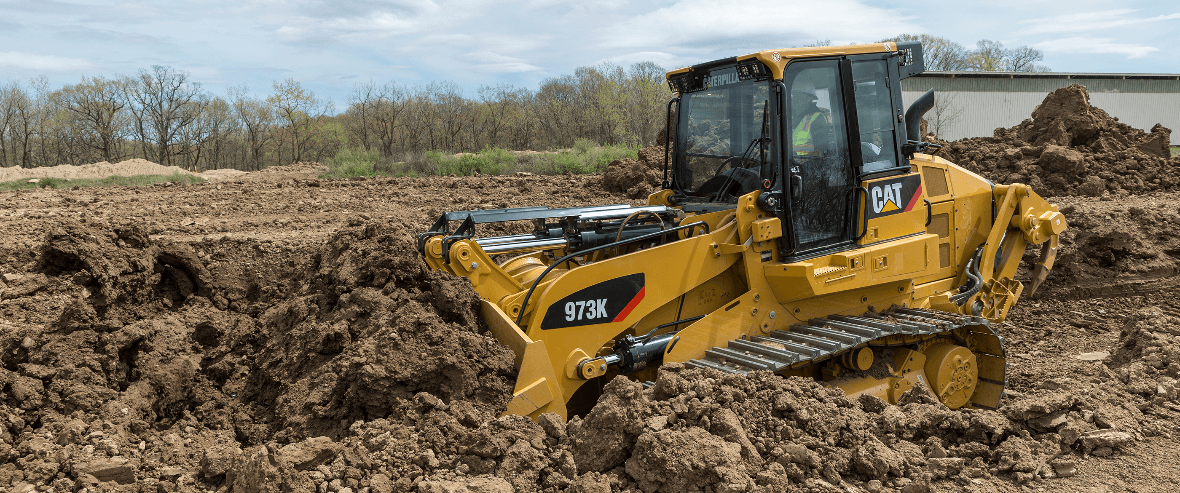

Different Types of Loaders: Backhoe, Skid Steer, Track, and Wheel Loaders

Learn about the different types of loaders available for renting from The Cat® Rental Store. Compare backhoe loaders, skid steers, compact track loaders, wheel loaders, and track loaders to find the right machine for your job.

Read More[Construction, Construction, lead gen, Awareness, Mining, existing customer, Mining, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

How To Handle Construction Materials Transportation

Learn how to plan, comply, and move materials safely. Get logistics basics, key material tips, handling equipment, and where to rent nearby from The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

What Size Bulldozer Do I Need? Bulldozer Rental Guide

Wondering what size bulldozer you need to rent? Learn how to choose the right dozer for your project. Compare small, medium, and large dozers, blade attachments, and rental benefits.

Read More[Construction, lead gen, existing customer, Cat Rental, Construction, Awareness, Land Management, Material Handling, Surface Mining, Landscaping, sales qualified lead, Forestry machinery, marketing qualified prospect, Consideration] -

Guide to Hurricane and Storm Cleanup Equipment Rentals

See the essential equipment for hurricane and storm cleanup. Rent bulldozers, loaders, dump trucks, and more from The Cat® Rental Store.

Read More[lead gen, Municipality, Awareness, existing customer, Demolition and Recycling, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

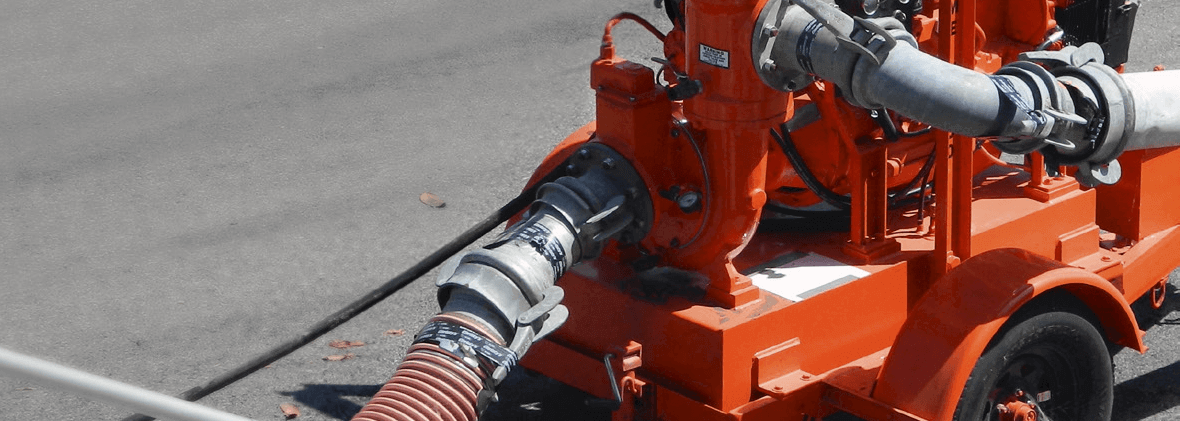

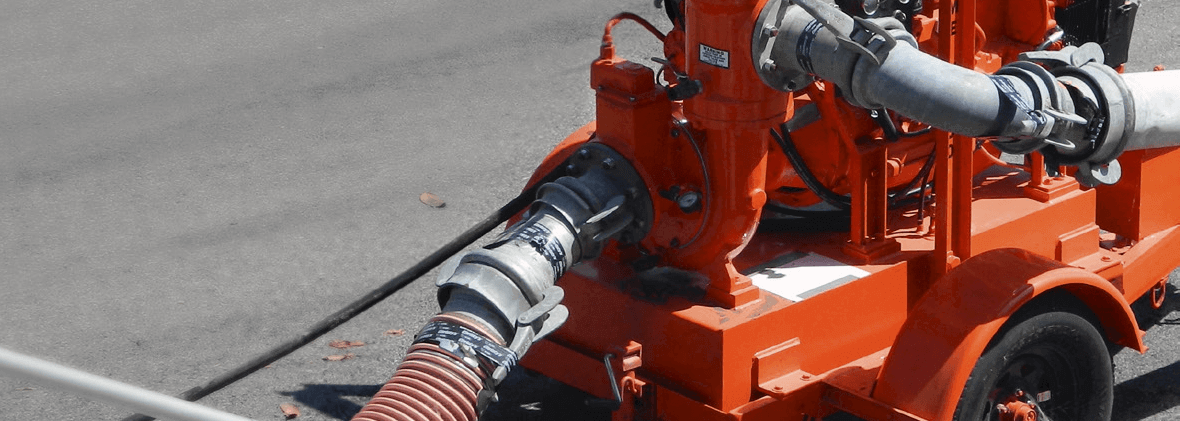

Pump Comparison: Portable vs. Submersible vs. Towable Pumps

Compare portable, submersible, and towable pumps for construction and industrial jobs. Learn key differences, best uses, and rental benefits from The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Five Tips for Renting a Bulldozer

Discover five essential tips for renting a bulldozer. Learn about sizes, insurance, rental support, and choosing the right provider with The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Heavy Equipment Rental Requirements: What You Need to Know

Learn the key requirements for renting heavy equipment, including insurance, licensing, training, and protection policies. Discover how The Cat® Rental Store can help.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Power Trowels: Walk-Behind vs. Ride-On for Concrete Finishing

Learn the difference between walk-behind and ride-on power trowels. Discover which type is best for your concrete finishing job and explore rental options at The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

The Best Skid Steer Attachments to Rent for Your Job

Discover the best skid steer attachments for construction, landscaping, and farming. From buckets and augers to rakes, trenchers and hammers, find out how renting expands skid steer versatility.

Read More[Construction, Construction, Awareness, Land Management, existing customer, Landscaping, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Equipment Rental Benefits for Contractors

Explore the top equipment rental benefits for your construction business, including cost savings, flexibility, access to new technology, and reduced maintenance costs.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Rental Equipment for Driveway Maintenance

Learn about rental equipment for driveway maintenance, from graders to sweepers. Find trusted OEM brands at The Cat® Rental Store.

Read More -

How to Get Construction Equipment Financing

Find out how construction equipment financing works, how it helps small businesses, and when rental might be a better option with help from The Cat® Rental Store.

Read More[time on page, Construction, Construction, lead gen, pageviews, Awareness, existing customer, locate dealer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

How to Make Concrete: Full Process Steps

Learn the steps of the concrete making process, from mixing to curing. Rent concrete mixers and equipment from The Cat® Rental Store for your next project.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Direct vs. Indirect Fired Heater Rental

Learn the differences between direct and indirect fired heaters, their pros and cons, and when to rent each type from The Cat® Rental Store.

Read More[Construction, Construction, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

The Tools Necessary for Underground Pipe Installation

Learn the simple tools needed for underground pipe installation, from excavators to compactors. Rent the right equipment from The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental, Pipeline] -

Benefits of Utility Vehicle Rentals on Construction Sites

Discover the many benefits of utility vehicles for construction sites, from mobility to safety. Rent UTVs from The Cat® Rental Store today.

Read More[Construction, Construction, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Concrete vs. Mortar vs. Cement

Learn the differences between concrete, mortar and cement and find the right rental equipment for your next project at The Cat® Rental Store.

Read More[time on page, Construction, Paving, lead gen, pageviews, existing customer, locate dealer, Cat Rental, Construction, Awareness, sales qualified lead, marketing qualified prospect, Consideration] -

Types of Asphalt Paver Rentals

Learn the differences between tracked and wheeled asphalt pavers, their pros and cons, and how to choose the right model for your project and budget.

Read More[time on page, Paving, Construction, lead gen, pageviews, Awareness, existing customer, locate dealer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

The Many Uses of Portable Air Compressors

Discover the many uses and benefits of portable air compressors across industries. Rent portable air compressors from The Cat® Rental Store today.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Compact Utility Loader Guide

Explore the uses, benefits, and attachments of compact utility loaders. Learn why renting from The Cat® Rental Store is the best option for your next project.

Read More[time on page, Construction, lead gen, pageviews, existing customer, locate dealer, Cat Rental, Construction, Awareness, Landscaping, sales qualified lead, Forestry machinery, marketing qualified prospect, Consideration] -

Why A Concrete Vibrators Rental Is Important

Learn why concrete vibrator rentals matter for strong, durable concrete. Discover types, benefits, and rental options from The Cat® Rental Store.

Read More[Construction, Paving, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Three Steps to Setting Up Temporary Power Solutions r

Learn the three essential steps to setting up temporary power on construction sites. Explore Cat® temporary power solutions and keep your projects safe and efficient.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Pressure Washer Rental vs. Hiring a Pro

Compare DIY pressure washer rental with hiring a professional service. Learn costs, benefits, and best uses, then rent from The Cat® Rental Store.

Read More[Commercial, lead gen, Awareness, existing customer, Landscaping, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Construction Equipment Management: Complete Guide

Discover best practices for construction equipment management, from storage to preventive maintenance. Rent Cat® equipment to keep your fleet efficient.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Wheel vs. Track Excavators: Comparison Guide

Learn the differences between wheel vs. track excavators, including speed, terrain, stability, and attachments. Find the right excavator for your job at The Cat® Rental Store.

Read More[Construction, lead gen, Mining, existing customer, Mining, Landfills, Cat Rental, Agriculture, Construction, Landscaping, sales qualified lead, marketing qualified prospect, Agriculture] -

Dewatering on Construction Sites

Learn what dewatering is, key methods, factors, and benefits. Explore why renting pumps and water equipment from The Cat® Rental Store helps keep your jobsite safe and efficient.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Should I Rent a Wheel Loader or Backhoe Loader?

Choose between wheel loaders or backhoe loaders by learning key differences, applications, and sizes. Rent the right machine for your project at The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Options for Pipeline Construction Equipment

Learn about the heavy equipment needed for each stage of pipeline construction, from clearing to pipelaying. Rent dependable machines from The Cat® Rental Store.

Read More[Oil and Gas, lead gen, Gas Compression, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental, Pipeline] -

Wheel Loader or Track Loader? Key Differences

Learn how to choose a wheel loader or track loader. Compare costs, terrain, and uses. Rent the right loader for your project from The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, Rental, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

What Is Asphalt Milling? | The Cat Rental Store

Learn how asphalt milling works, when to use it, the process, equipment involved, and its benefits. Rent cold planers, sweepers, and more from The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

What It’s Like Working in Construction | The Cat® Rental Store

Thinking about a construction career? Learn what the work is like and the training you may need. See how The Cat® Rental Store supports working in construction with reliable rentals.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Benefits of Remixing Transfer Vehicles

Learn how remixing transfer vehicles improve paving with smoother surfaces, easier cleanup, and higher productivity. Rent dependable Weiler equipment from The Cat® Rental Store.

Read More[Construction, Paving, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

How Many Cubic Yards Can My Dump Truck Carry? | The Cat® Rental Store

Learn how to calculate dump truck capacity in cubic yards. Understand volume, weight, and material factors and rent dependable dump trucks from The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Tools for Underground Cable Installation

Learn about five essential tools for underground cable installation. Rent dependable equipment from The Cat® Rental Store to get the job done right.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental, Telecom] -

Top Seven Uses for Excavators

With an excavator, you can perform multiple tasks necessary in many heavy industries. Discover the top uses with The Cat Rental Store.

Read More -

Heavy Equipment vs. Compact Equipment: Rental Guide

Compare heavy and compact equipment rentals. Learn pros, cons, and which option fits your project with The Cat® Rental Store.

Read More[time on page, Construction, Construction, lead gen, pageviews, Awareness, existing customer, locate dealer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Types of Stump Grinders: How to Choose the Right One

Learn the differences between stump grinder types and how to pick the right machine for your job. Explore rentals, safety tips, and FAQs from The Cat® Rental Store.

Read More[time on page, lead gen, pageviews, existing customer, locate dealer, Cat Rental, Awareness, Forestry, Landscaping, sales qualified lead, Forestry machinery, marketing qualified prospect, Consideration] -

Tools for Mixing Concrete: How to Choose the Right One

Learn about tools for mixing concrete, from buckets to mortar mixers. See how to choose the right tool for your project and explore rentals at The Cat® Rental Store.

Read More[time on page, Construction, Construction, lead gen, pageviews, Awareness, existing customer, locate dealer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

What Are Some Common Construction Drills Uses?

Learn the top uses of construction drills, including foundation, blasting and fencing projects. Explore rental options at The Cat® Rental Store.

Read More[time on page, Construction, Construction, lead gen, pageviews, Awareness, existing customer, locate dealer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

When to Rent Construction Equipment

Discover the best time to rent construction equipment. Learn when renting makes sense, the benefits of seasonal rentals, and which trusted OEMs are available from The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Seven Benefits of Renting Your Work Trucks

Learn why road crews, contractors, utility workers, quarries and more rent their work trucks from The Cat Rental Store.

Read More -

Rental Equipment for Lawn Care

Explore lawn care equipment rentals, from skid steers to attachments. Learn how seasonal availability, cost savings, and flexibility help grow your landscaping business.

Read More[lead gen, Awareness, Land Management, existing customer, Landscaping, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Tips for Renting a Trailer

Learn essential trailer rental tips, from choosing the right type to insurance, towing, budgeting, and quality brands. Explore trailer rentals at The Cat® Rental Store.

Read More[time on page, Construction, Construction, lead gen, pageviews, Awareness, existing customer, locate dealer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Tax Benefits of Renting Equipment | Maximize Your Savings

Discover the tax benefits of renting equipment. Learn how to maximize deductions, reduce costs, and improve cash flow with The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, locate dealer, existing customer, time on page, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

How to Use Different Types of Trenchers

Learn how to use walk-behind and ride-on trenchers for construction, landscaping, and utility work. Discover trencher rental benefits and applications.

Read More[Construction, Agriculture, Construction, lead gen, Awareness, existing customer, Landscaping, sales qualified lead, marketing qualified prospect, Agriculture, Consideration, Cat Rental] -

Financial Benefits of Equipment Rental for Large Business Owners

Discover how renting construction equipment can save costs, boost flexibility, and free capital for large businesses. Learn key benefits and future rental trends.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

How Equipment Rental Reduces Downtime During Maintenance

Discover how equipment rental downtime solutions keep your projects moving. Learn how renting covers planned and unplanned downtime while saving costs and boosting productivity.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Renting Equipment and How It Keeps You Versatile and Competitive

Discover the versatility of renting equipment. Learn why contractors rent, the benefits, and how rentals open doors to more opportunities.

Read More[lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

How to Manage Rental Equipment Effectively: Portals, Tips, and Best Practices

Discover how to manage rental equipment effectively. Learn about rental portals, customer expectations, service requests, and practical tips to maximize your rentals.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Mistakes to Avoid When Renting Equipment: A Contractor’s Guide

Avoid costly equipment rental mistakes. Learn common errors contractors make when renting construction equipment and how to rent smarter with The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Farm Uses for a Skid Steer: Attachments and Applications

Explore the top farm uses for a skid steer, from hauling feed and handling hay to mowing, grading and snow removal. Learn how renting a farm skid steer improves efficiency year-round.

Read More[Agriculture, lead gen, support and service personnel, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Agriculture, Consideration, Cat Rental] -

Rental Equipment for Independent Contractors: The Flexibility You Need

Independent contractors often need reliable tools and machines. Learn why contractor equipment rental is on the rise, its benefits, and tips to rent smarter from The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Guide to Long-Term Equipment Rentals: Benefits and Best Practices

Understand the advantages of long-term equipment rentals, from predictable costs and maintenance support to flexibility and competitive edge. Learn how to plan your rental strategy.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Guide to Budgeting for Rental Equipment in Construction

Learn how construction equipment rental budgeting works, including cost factors, rental periods and strategies to save money. Get tips to keep your projects profitable.

Read More[Construction, Construction, lead gen, Awareness, existing customer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Ultimate Guide to Renting Earthmoving Equipment

Discover the benefits of renting earthmoving equipment like dozers, excavators, loaders, and graders. Learn about applications, cost savings, and how to choose the right rental machine.

Read More[lead gen, Awareness, Mining, existing customer, Mining, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Backhoe Attachment vs. Backhoe Loader: Which Should You Rent?

Compare backhoe attachments and backhoe loaders to see which one is right for your job. Learn about cost, ease of use and rental options at The Cat® Rental Store.

Read More[time on page, Construction, Construction, lead gen, pageviews, Awareness, existing customer, locate dealer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

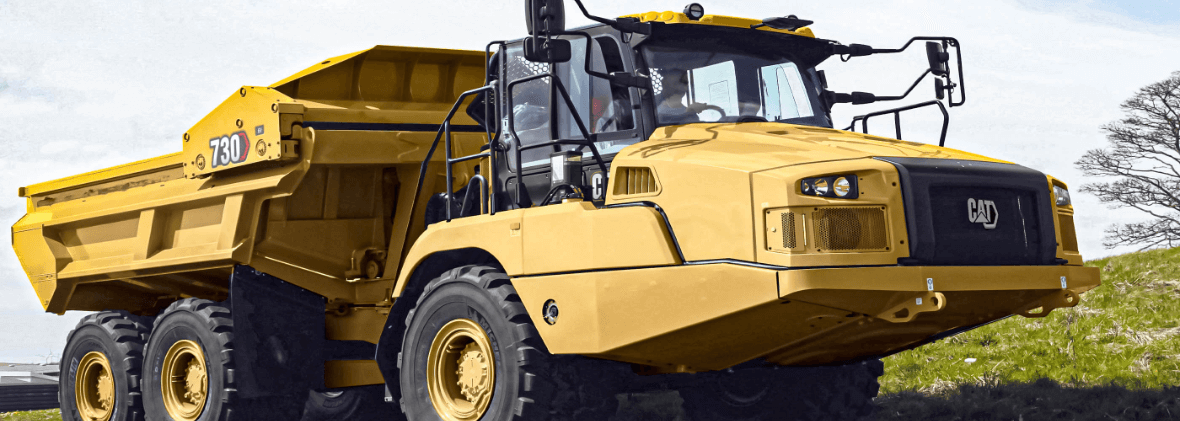

What Is an Articulated Truck?

Learn what an articulated truck is, how it works, and why it’s useful for construction, mining and demolition projects. Find rental options at The Cat® Rental Store.

Read More[time on page, Construction, lead gen, pageviews, Mining, existing customer, locate dealer, Demolition and Recycling, Mining, Cat Rental, Construction, Awareness, sales qualified lead, marketing qualified prospect, Consideration] -

The Easiest Way To Remove A Tree

Learn the easiest ways to remove a tree with the right equipment. Explore brush chippers, stump grinders, mulchers and rental options from The Cat® Rental Store.

Read More[time on page, lead gen, pageviews, existing customer, locate dealer, Cat Rental, Awareness, Forestry, Landscaping, sales qualified lead, Forestry machinery, marketing qualified prospect, Consideration] -

Should I Use a Utility Trailer When Moving?

Learn whether a utility trailer is the right choice for your move. Compare trailers vs. moving trucks and explore rental options at The Cat® Rental Store.

Read More[Construction, lead gen, pageviews, existing customer, time on page, Cat Rental, Construction, Awareness, locate dealer, Land Management, Landscaping, sales qualified lead, marketing qualified prospect, Consideration] -

The Benefits of Using a Wood Chipper

Learn the top benefits of using a wood chipper for site clearing and recycling. Discover how brush chippers save time and reduce waste with The Cat® Rental Store.

Read More[time on page, lead gen, pageviews, existing customer, locate dealer, Logging, Cat Rental, Awareness, Forestry, Landscaping, sales qualified lead, Forestry machinery, marketing qualified prospect, Consideration] -

Bulldozer Types and Their Uses

Learn about bulldozer types and their uses in construction and other applications. Rent bulldozers at The Cat® Rental Store.

Read More[Construction, time on page, lead gen, pageviews, Mining, existing customer, locate dealer, Mining, Cat Rental, Construction, Awareness, sales qualified lead, marketing qualified prospect, Consideration] -

How to Safely Use a Brush Chipper

Learn brush chipper safety tips for site clearing and tree removal. Discover proper setup, feeding, PPE and rental options with The Cat® Rental Store.

Read More[time on page, lead gen, pageviews, existing customer, locate dealer, Logging, Cat Rental, Awareness, Forestry, Landscaping, sales qualified lead, Forestry machinery, marketing qualified prospect, Consideration] -

All About Excavators: A Comprehensive Guide

Everything you need to know about excavators — history, parts, types, uses, attachments, sizes, and rental options from The Cat® Rental Store.

Read More[time on page, Construction, Paving, lead gen, pageviews, existing customer, locate dealer, Demolition and Recycling, Landfills, Cat Rental, Construction, Awareness, Forestry, Quarry Aggregates, sales qualified lead, Forestry machinery, marketing qualified prospect, Consideration] -

14 Essential Construction Attachments Explained

Explore 14 essential construction attachments, grouped by type. Learn how augers, grapples, breakers, blades and more can expand your fleet with The Cat® Rental Store.

Read More[time on page, Construction, Construction, lead gen, pageviews, Awareness, existing customer, locate dealer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Types of Rollers For Construction Projects

Learn about the most common types of rollers used for soil compaction in construction. Compare walk-behind vs. ride-on rollers and explore rental options at The Cat® Rental Store.

Read More[time on page, Construction, Paving, lead gen, pageviews, existing customer, locate dealer, Cat Rental, Construction, Awareness, sales qualified lead, marketing qualified prospect, Consideration] -

The Many Uses of Skid Loaders

Discover the many uses of skid steer loaders, from landscaping to road building. Learn the benefits of renting skid loaders from The Cat® Rental Store.

Read More[time on page, Construction, lead gen, pageviews, existing customer, locate dealer, Cat Rental, Construction, Awareness, Forestry, sales qualified lead, marketing qualified prospect, Consideration] -

What Is a Front-End Loader and What Is It Used For?

Learn what a front-end loader is, its key features, attachments and uses across industries. Explore loader rentals at The Cat® Rental Store.

Read More[time on page, Construction, lead gen, pageviews, existing customer, locate dealer, Cat Rental, Agriculture, Construction, Awareness, Snow and Ice, sales qualified lead, marketing qualified prospect, Agriculture, Consideration] -

What Are Motor Graders Used For?

Discover the top uses of motor graders in construction, roadwork, snow removal, mining and more. Learn about key attachments and rental benefits from The Cat® Rental Store.

Read More[time on page, Construction, Paving, lead gen, pageviews, existing customer, locate dealer, Cat Rental, Construction, Awareness, sales qualified lead, marketing qualified prospect, Consideration] -

Backhoe vs. Excavator: Which One Should You Rent?

Compare backhoes and excavators for digging, earthmoving and site work. Learn key differences and find rental options at The Cat® Rental Store.

Read More[time on page, Construction, lead gen, pageviews, Mining, existing customer, locate dealer, Demolition and Recycling, Mining, Cat Rental, Agriculture, Construction, Awareness, Landscaping, sales qualified lead, marketing qualified prospect, Agriculture, Consideration] -

Water Pumps vs. Trash Pumps: Which One Should You Rent?

Compare water pumps and trash pumps for construction, agriculture and dewatering. Learn the differences and find the right rental pump at The Cat® Rental Store.

Read More[time on page, Gov Local State, lead gen, pageviews, existing customer, locate dealer, Cat Rental, Construction, Municipality, Well Service, Awareness, Landscaping, sales qualified lead, marketing qualified prospect, Consideration] -

Cold Planers and Concrete Recycling Explained

Learn how cold planers work, why concrete recycling matters and the benefits for your projects. Explore rental options at The Cat® Rental Store.

Read More[time on page, Construction, Construction, lead gen, pageviews, Awareness, existing customer, locate dealer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

What Is Forestry Mulching and Why It Matters

Learn what forestry mulching is, the equipment it requires and five key benefits. Discover Cat® mulchers, skid steers and brush chippers available for rent at The Cat Rental Store.

Read More[time on page, lead gen, pageviews, Awareness, Forestry, existing customer, locate dealer, sales qualified lead, Forestry machinery, marketing qualified prospect, Consideration, Cat Rental] -

3 Types of Man Lifts: A Complete Guide

Learn about boom lifts, scissor lifts and vertical personnel lifts. Discover which type of man lift fits your job and explore rentals from The Cat® Rental Store.

Read More[time on page, Construction, Construction, lead gen, Awareness, existing customer, locate dealer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

5 Ways to Recycle Wood Chips: Compost, Bedding and More

Discover 5 ways to recycle wood chips, from mulch and compost to paths and bedding. Learn how a rental brush chipper from The Cat® Rental Store can help.

Read More[time on page, lead gen, pageviews, existing customer, locate dealer, Cat Rental, Awareness, Forestry, Landscaping, sales qualified lead, Forestry machinery, marketing qualified prospect, Consideration] -

When and How to Relocate a Tree Safely

Learn the best time to relocate a tree, step-by-step transplanting tips and how a rental tree spade from The Cat® Rental Store makes relocation easier.

Read More[time on page, lead gen, pageviews, existing customer, locate dealer, Cat Rental, Awareness, Forestry, Landscaping, sales qualified lead, Forestry machinery, marketing qualified prospect, Consideration] -

Single Drum vs. Double Drum Rollers: Which Should You Rent?

If your projects require surface preparation, you may benefit from using a road roller. Learn if you need a single or double drum roller for your project.

Read More[time on page, Paving, Construction, lead gen, pageviews, Awareness, existing customer, locate dealer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

The Ultimate Guide to Tree Work

Learn what tree work is, the main types of equipment involved and why renting with The Cat® Rental Store can keep your projects flexible, affordable and productive.

Read More[time on page, lead gen, pageviews, Awareness, Forestry, existing customer, locate dealer, sales qualified lead, Logging, marketing qualified prospect, Consideration, Cat Rental] -

How to Plan a Budget for a Construction Project

Learn how to plan a construction budget. Discover what costs to expect, how to prepare for surprises and ways rentals can help keep projects on track with The Cat® Rental Store.

Read More[time on page, Construction, Construction, lead gen, pageviews, Awareness, existing customer, locate dealer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Bulldozer vs. Wheel Loader: How to Choose the Right Rental

Compare bulldozers vs. wheel loaders to find the right rental. Learn key differences, applications tips for choosing the right earthmoving equipment with The Cat® Rental Store.

Read More[time on page, Construction, lead gen, pageviews, Mining, existing customer, locate dealer, Mining, Cat Rental, Construction, Awareness, sales qualified lead, marketing qualified prospect, Consideration] -

How to Choose the Right Equipment Rental Partner

Learn how to choose the right equipment rental partner. Discover what to look for in quality, selection, service, and support with The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, locate dealer, existing customer, Rental, time on page, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

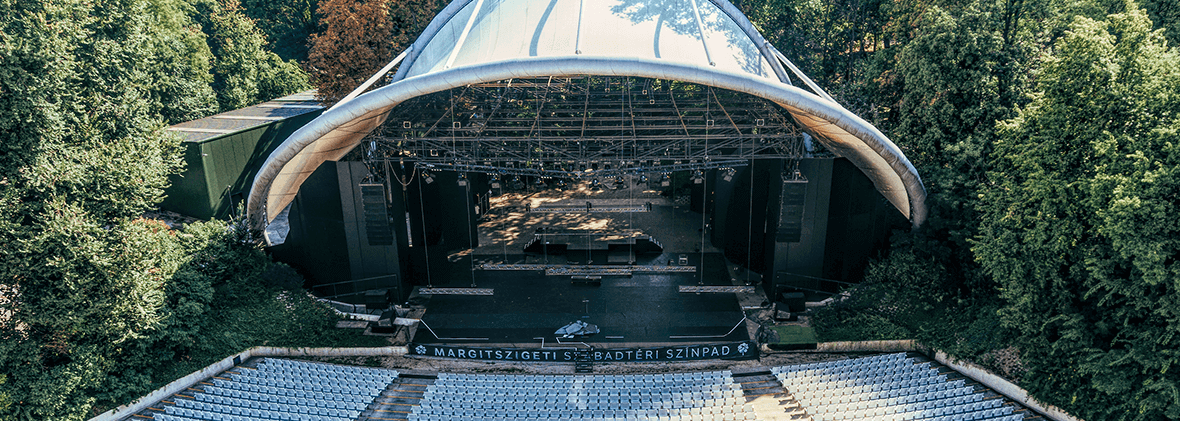

The Ultimate Event Construction Needs Checklist

Plan your event with confidence. Explore this ultimate construction checklist covering essential rentals, safety, and site prep with The Cat® Rental Store.

Read More[Construction, Construction, lead gen, Awareness, locate dealer, existing customer, time on page, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Pumping Equipment Rentals: Uses and Benefits

Explore the benefits of pumping equipment rentals. Learn about pump types, key applications, and why renting is a cost-effective choice for your business.

Read More[time on page, Construction, lead gen, pageviews, Mining, existing customer, locate dealer, Rental, Mining, Cat Rental, Agriculture, Commercial, Awareness, sales qualified lead, marketing qualified prospect, Agriculture, Consideration] -

Benefits of Renting High-Quality Construction Equipment

Discover the benefits of renting high-quality construction equipment. Learn how premium rentals improve safety, reliability, performance, and cost efficiency for your projects.

Read More[time on page, Construction, Construction, lead gen, pageviews, Awareness, existing customer, locate dealer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Why It Makes Sense to Why Rent Attachments Instead of Buying Them Rent Attachments

Learn the top attachment rental benefits, popular attachment types by task, and tips to choose the right setup. Get more done with The Cat® Rental Store.

Read More[time on page, Construction, lead gen, pageviews, existing customer, locate dealer, Rental, Cat Rental, Construction, Awareness, sales qualified lead, Forestry machinery, marketing qualified prospect, Consideration] -

Orchard and Vineyard Equipment Rental Tips

Discover orchard and vineyard equipment rental tips. Learn which machines to rent for soil prep, harvest, and hauling while cutting costs with The Cat® Rental Store.

Read More[time on page, Agriculture, lead gen, pageviews, Awareness, existing customer, locate dealer, sales qualified lead, marketing qualified prospect, Agriculture, Consideration, Cat Rental] -

Long-Term Equipment Rental Benefits to Boost Productivity

Discover the benefits of long-term equipment rental, from Cat® technology to cost savings and sustainability. Learn how The Cat Rental Store supports your business.

Read More[time on page, Construction, lead gen, pageviews, existing customer, locate dealer, Rental, Cat Rental, Construction, Awareness, sales qualified lead, marketing qualified prospect, Consideration] -

Landscaping Equipment Rental Tips for Beginners

Learn 8 essential landscaping equipment rental tips for beginners. Discover how to choose the right machines, save money, and work safely with The Cat® Rental Store.

Read More[time on page, lead gen, existing customer, locate dealer, time on page, Cat Rental, Awareness, locate dealer, Land Management, Landscaping, sales qualified lead, marketing qualified prospect, Consideration] -

How to Return Rental Equipment the Right Way

Learn how to return rental equipment with ease. Follow simple steps to prepare, schedule, and extend rentals. The Cat® Rental Store makes the process seamless.

Read More[time on page, Construction, lead gen, pageviews, existing customer, locate dealer, Rental, Cat Rental, Construction, Awareness, sales qualified lead, marketing qualified prospect, Consideration] -

Benefits of Renting Floor Scrubbers

Discover the benefits of floor scrubber rentals, from cost savings to flexibility and updated technology. Learn how The Cat® Rental Store supports your cleaning needs.

Read More[time on page, Construction, lead gen, pageviews, existing customer, locate dealer, Rental, Cat Rental, Construction, Awareness, sales qualified lead, marketing qualified prospect, Consideration] -

Rental Equipment Maintenance: Tips for Long-Term Use

Explore 14 essential rental equipment maintenance tips with examples and scenarios. Keep machines safe, reliable, and efficient with The Cat® Rental Store.

Read More[time on page, Construction, lead gen, pageviews, existing customer, locate dealer, Rental, Cat Rental, Construction, Awareness, sales qualified lead, marketing qualified prospect, Consideration] -

Disaster Recovery Equipment Rentals — What to Rent and Why

Build an equipment rental plan for natural disaster recovery. See which machines to rent after hurricanes, floods, wildfires, and more and learn how The Cat® Rental Store supports you.

Read More[time on page, Construction, lead gen, pageviews, Awareness, existing customer, locate dealer, Demolition and Recycling, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Tips for First-Time Equipment Rental

Explore essential equipment rental advice for first-time renters. Learn how to plan, avoid hidden fees, and get the most from your rentals with The Cat® Rental Store.

Read More[time on page, Construction, Gov Local State, Paving, lead gen, pageviews, Waste, existing customer, locate dealer, Land Drilling, Gov Defense, Cat Rental, Commercial, Construction, Municipality, Well Service, Awareness, Material Handling, Military, sales qualified lead, marketing qualified prospect, Consideration] -

When to Rent Construction Equipment Instead of Buy

Learn when to rent vs. buy construction equipment. Explore 10 key considerations, cost savings, and benefits of renting with The Cat® Rental Store.

Read More[time on page, Construction, Construction, pageviews, Awareness, existing customer, locate dealer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Tools and Attachments for Concrete Jobs

Discover top tools and attachments for concrete jobs, including hammers, saws, buggies, mixers, and trowels. Learn when to rent and how to choose the right equipment.

Read More[time on page, Construction, Construction, lead gen, pageviews, Awareness, existing customer, locate dealer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Renting Equipment for Wildfire Cleanup

Learn which equipment is best for wildfire cleanup. Discover the benefits of renting dozers, excavators, loaders, and track loaders from The Cat® Rental Store.

Read More[time on page, lead gen, pageviews, Awareness, Forestry, existing customer, locate dealer, sales qualified lead, Consideration, Cat Rental] -

How to Scale Up Your Business With Rental Equipment

See how renting equipment can help your business grow. Learn how rentals improve ROI, boost bids, expand opportunities, and give access to the latest technology.

Read More[time on page, Construction, lead gen, pageviews, ADIAUD, existing customer, locate dealer, Cat Rental, Construction, Awareness, sales qualified lead, marketing qualified prospect, Consideration] -

What to Know About Renting a Mulcher: Features, Applications and Benefits

Explore how mulcher rentals can transform land management. Learn about Cat mulcher features, forestry applications, safety benefits, and rental advantages.

Read More[time on page, lead gen, pageviews, existing customer, locate dealer, Rental, Cat Rental, Agriculture, Awareness, Forestry, Material Handling, Landscaping, sales qualified lead, Forestry machinery, marketing qualified prospect, Agriculture, Consideration] -

6 Must-Ask Questions About Construction Equipment Rental

Explore six must-ask questions about construction equipment rentals, from project type to operator skill. Learn what to rent and how to save with The Cat® Rental Store.

Read More[time on page, Construction, Construction, lead gen, pageviews, Awareness, existing customer, locate dealer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Attachment Rentals for Paving Projects

Explore paving attachment rentals, including cold planers, compactors, saws, breakers, and brooms. Rent from The Cat® Rental Store.

Read More[Construction, Paving, Construction, lead gen, Awareness, locate dealer, existing customer, time on page, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

What Is Hydraulic Equipment and Why It Matters for Heavy Industry

Understand what hydraulic equipment is, how it works and why it matters in construction and mining. Learn the benefits of hydraulics and where to rent hydraulic equipment.

Read More[time on page, Construction, lead gen, pageviews, Mining, existing customer, locate dealer, Mining, Landfills, Cat Rental, Construction, Awareness, Forestry, Quarry Aggregates, Landscaping, sales qualified lead, Underground Mining, marketing qualified prospect, Consideration] -

Tips for Pouring Concrete in the Winter: Equipment and Preparation

Pouring concrete in the winter requires special steps to prevent cracking and strength loss. Learn the best tips, mixes and rental equipment to ensure successful cold-weather concrete projects.

Read More[time on page, lead gen, pageviews, Awareness, existing customer, locate dealer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

On-Highway vs. Off-Highway Dump Truck Rental: Which Is Best for Your Job?

Compare on-highway and off-highway dump trucks by load capacity, terrain and applications. Find out which dump truck rental is right for roadwork, mining or earthmoving.

Read More[Construction, lead gen, Mining, existing customer, time on page, Mining, Cat Rental, Construction, Awareness, locate dealer, sales qualified lead, marketing qualified prospect, Consideration] -

What Is a Super Long Reach Excavator? Uses, Benefits and Rental Options

Whether your next job is on a mining site or a reservoir, renting a long-reach excavator is helpful. Learn more about the applications and benefits today!

Read More[time on page, Construction, lead gen, pageviews, Mining, existing customer, locate dealer, Mining, Cat Rental, Construction, Awareness, Landscaping, sales qualified lead, marketing qualified prospect, Consideration] -

What Is a Skip Loader and When Should You Rent One?

The Cat Rental is your one-stop headquarters for versatile, high-performing skip loader rentals. Contact us for more information and a fast quote.

Read More[time on page, Construction, Paving, lead gen, pageviews, existing customer, locate dealer, Cat Rental, Construction, Awareness, Landscaping, sales qualified lead, marketing qualified prospect, Agriculture, Consideration] -

Reasons to Rent Equipment for Highway Construction Projects

Explore why renting highway construction equipment is a cost-effective and flexible option. Learn about pavers, compactors, dozers, graders and other rentals available for roadwork projects.

Read More[time on page, Construction, Construction, lead gen, Awareness, existing customer, locate dealer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

What Is Trench Shoring? Methods, Equipment, and Rental Benefits

Understand trench shoring methods and equipment, including aluminum and steel trench boxes, hydraulic systems, and trenchers. Learn why renting trench shoring equipment saves costs.

Read More[time on page, Construction, Construction, lead gen, Awareness, existing customer, locate dealer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Smooth Drum Roller vs. Padfoot Roller: Choosing the Right Compactor Rental

Compare smooth drum and padfoot rollers for soil and asphalt compaction. Learn how to pick the right roller for your project and how The Cat® Rental Store can help.

Read More[time on page, Paving, lead gen, pageviews, Awareness, existing customer, locate dealer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Concrete Grinder vs. Scarifier: Which Rental Is Right for Your Project?

Learn the key differences between concrete grinders and scarifiers, including depth, speed, finish and applications. Find out which rental equipment best fits your project needs.

Read More[Construction, Paving, Construction, lead gen, Awareness, locate dealer, existing customer, time on page, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

All About Vacuum Trucks: Types, Uses, How They Work and Rentals

Learn what vacuum trucks are, how hydro and dry vacs work, key applications and when to choose a vacuum truck rental.

Read More[time on page, Construction, Construction, Awareness, existing customer, locate dealer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

What Is the Most Used Machine in Construction? Top 10 Machines Explained

Discover the most used machines in construction. Learn about excavators, skid steers, loaders, dozers, graders and more — plus rental options from The Cat Rental Store.

Read More[time on page, Construction, Construction, lead gen, pageviews, Awareness, existing customer, locate dealer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

What Classifies As Heavy Equipment?

Heavy equipment appears on numerous job sites. Visit our website today to learn more about what makes a machine "heavy equipment" and how it's used.

Read More[time on page, Construction, lead gen, pageviews, Mining, existing customer, locate dealer, Mining, Cat Rental, Construction, Awareness, sales qualified lead, marketing qualified prospect, Consideration] -

What Equipment Do You Need to Pour a Concrete Sidewalk?

Learn the essential tools and equipment needed to pour a concrete sidewalk, from mixers to vibrators. Rent concrete equipment from The Cat® Rental Store.

Read More[time on page, Construction, Paving, lead gen, pageviews, existing customer, locate dealer, Mining, Cat Rental, Construction, Awareness, Material Handling, sales qualified lead, marketing qualified prospect, Consideration] -

Winter Equipment Rental: Why It Makes Sense

Learn why winter equipment rental helps you control costs and stay productive. See recommended machines by use case, key attachments, and tips from The Cat® Rental Store.

Read More[time on page, Construction, lead gen, pageviews, Awareness, existing customer, Snow and Ice, locate dealer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

How to Choose a Heater Rental for Your Work Site

Learn how to choose the right work site heater rental. Explore heater types, factors to consider, FAQs, and rental support from The Cat® Rental Store.

Read More[time on page, Construction, Construction, lead gen, pageviews, Awareness, existing customer, locate dealer, sales qualified lead, marketing qualified prospect, Consideration, Cat Rental] -

Renting a Generator to Charge Electric Equipment

Learn how generator rentals power electric equipment on construction sites. Explore benefits, how to choose the right generator, and rental options from The Cat® Rental Store.

Read More[time on page, Construction, lead gen, pageviews, existing customer, locate dealer, Electric Power Generation, Cat Rental, Construction, Awareness, sales qualified lead, marketing qualified prospect, Consideration] -

Types of Equipment Used in Industrial Construction

Learn about essential industrial construction equipment, including earthmoving, transportation, material handling, concrete tools, and more.

Read More[time on page, Paving, Construction, lead gen, pageviews, Mining, existing customer, Utilities, locate dealer, Mining, Landfills, Cat Rental, Construction, Commercial, Awareness, Forestry, Quarry Aggregates, Landscaping, sales qualified lead, Forestry machinery, marketing qualified prospect, Agriculture, Consideration] -

Comprehensive Guide to Land Clearing Equipment: Machines, Attachments, and Rental Benefits

Explore essential land clearing equipment in detail. Learn about dozers, excavators, skid steers, attachments, and the benefits of renting from The Cat Rental Store.

Read More[time on page, Construction, lead gen, pageviews, existing customer, locate dealer, Cat Rental, Construction, Awareness, Forestry, Land Management, Landscaping, sales qualified lead, Forestry machinery, marketing qualified prospect, Consideration] -

Making Sure You Have the Correct Licenses and Permits

Learn more about common construction permits and licenses you may need to complete your next project, then get the machines you need from The Cat Rental Store.

Read More -

Lean Material Handling: Efficient Warehousing

Reduce warehouse waste and create a more effective work environment by using lean material handling solutions. Learn more with The Cat Rental Store.

Read More -

How to Choose a Commercial Contractor

If you're looking to hire a commercial contractor, it's essential to do your research. Here are the top tips for how to choose the right contractor.

Read More -

Best Tips for a Safe Construction Site Reopening

As many contractors look to reopen their construction sites, they must take careful steps to ensure workers stay safe. Learn more with The Cat Rental Store.

Read More -

Why Should You Aerate?

Do you have questions about aeration and the benefits it can provide to your lawn? The Cat Rental Store has the answers. Contact us to learn more.

Read More -

How to Stay Safe in Confined Construction Site Spaces

Confined spaces come with risks. When you know how to handle these risks safely, you can protect your entire team. Learn more on safety from Caterpillar.

Read More -

Power Line Awareness on the Job Site

Avoid accidental contact with overhead or underground powerlines on construction sites by knowing how to identify them beforehand and creating a safety plan.

Read More -

10 Often-Neglected Construction Hazards

By understanding commonly neglected construction site hazards, you improve your safety through proactive measures. Learn more with The Cat Rental Store.

Read More -

How to Sanitize Construction Equipment

In a time when communicable viruses pose a substantial health threat, it's essential to sanitize machinery. Learn tips with The Cat Rental Store.

Read More -

4 Most Common Construction Injuries and How to Prevent Them

Construction work can present many hazards. Read on to learn the four most common construction injuries and how to avoid them.

Read More -

Steps to Being OSHA Compliant

OSHA creates guidelines for employers to follow to ensure the safety of their employees. Follow our guide to be OSHA compliant and more productive.

Read More -

The Importance of 811

When you're planning an excavation project on a residential or commercial property, digging safety is the number one priority. Learn the importance of 811.

Read More -

Seven Tips to Prevent Construction Site Theft

A proactive approach to construction site security can increase your job site's efficiency and safety. Learn with The Cat Rental Store.

Read More -

The Safest Way to Start Diverting Traffic During Construction

On a road construction project, redirecting traffic is an essential part of keeping everyone safe. Here are some tips on how to begin diverting traffic.

Read More -

What Is Tilt-up Construction?

Tilt-up construction is a dependable and efficient building process with many significant benefits. Rent construction equipment at The Cat Rental Store today!

Read More -

Plaster vs. Drywall

You'll find many differences when working with plaster vs. drywall, including composition, cost, process and more. Rent equipment for your next project today!

Read More -

What Is a Building Envelope?

What is a building envelope, and how does it affect your construction operations? The Cat Rental Store breaks down building envelope construction.

Read More -

Is the Construction Industry Right for You?

Do your personality and skills fit with a career in the construction industry? Check out this guide to determine if construction is right for you!

Read More -

Tips to Protect Workers' Hearing on Construction Sites

You can learn how to protect your hearing on the construction site with our noise protection tips. Contact The Cat Rental Store for a quote on a quiet machine!

Read More -

What Is a Construction Foreman?

The Cat Rental Store has the equipment for your construction needs, whether you work in the residential, commercial or industrial sector. Contact us today.

Read More -

The Types of Foundations in Construction

All solid structures start with a sturdy foundation. Learn the different types of foundations and how to identify them with The Cat Rental Store!

Read More -

How to Read Construction Blueprints

Construction blueprints can be complicated to read, but we can help. Learn how we can help you with your construction projects and equipment needs!

Read More -

5 Most Valuable Construction Skills

Construction work is highly versatile, and workers must be able to handle all kinds of tasks and environments. Learn the most valuable construction skills.

Read More -

Guide to Becoming a Crane Operator

Interested in becoming a crane operator? Find out what you need to do to enter this field and what industries you may be able to find work in.

Read More -

Construction Certifications: The Ultimate Guide

If you're in the construction industry, you know how critical it is to have the proper certifications before you get to work. Follow our ultimate guide.

Read More -

Types of Steel Used in Construction

Steel is suitable for a variety of construction applications. Discover the four main types of steel and some of its alloys to find the best material for you.

Read More -

7 of the Best and Highest-Paying Construction Jobs

With plenty of job opportunities and high economic demand, the construction industry has a lot to offer workers. Learn more with The Cat Rental Store.

Read More -

What is Value Engineering in Construction?

Value engineering increases a product's value by both improving functionality and keeping costs low. Request a quote for tools from The Cat Rental Store today.

Read More -

How Are Bridges Built Over Water?

How are bridges built over water? Find out and learn more about the equipment and materials involved. Get bridge work equipment from The Cat® Rental Store today.

Read More -

Is Electrical Equipment Rental Right For You?

Wondering if renting equipment is right for your electrical business? Read on to learn more about the benefits of renting electrical equipment!

Read More -

The Importance of Quality Rental Equipment for Successful Projects

The Cat Rental Store offers high-quality heavy equipment that improves project results. Contact us for more information and a quick rental quote.

Read More -