Readying Heavy Equipment for the Spring

As the temperature starts to rise and more construction jobs roll in, heavy machine owners learn the value of spring cleaning. If they live in a climate with long winters, the cold months can bring work to a halt, spelling out long periods of storage or idleness for their equipment. Winter can take its toll on these vehicles, with the cold temperatures, moisture and inclement weather. However, with proper care and attention, these machine owners can keep equipment in good condition, preventing breakdowns and lengthening the life of the machine.

So what exactly does readying construction equipment for spring entail? Construction spring cleaning involves a variety of tasks, from regular maintenance to repairs and record-keeping. In this guide, we'll walk you through the process and explain how the different tasks can benefit your equipment and operation.

Jump to a section:

Importance of Preparation

While most people are outside enjoying the beautiful new weather, prepping your machine might be the last thing on your mind — but you can't skip this vital step. Preparing your heavy machinery for spring is necessary for a smooth transition into the working season. Without appropriate care, you can create safety hazards and extensive repair costs. You could be guzzling more fuel than necessary due to a leak or pushing your machine through an agonizing engine malfunction without realizing it.

Readying your construction equipment for spring offers several benefits, including:

- Eliminating downtime: You may have already been out of commission during the winter, and the last thing you want is to spend more time out of work than necessary. By preparing your equipment as soon as the weather starts to warm up, you reduce your risk for maintenance problems that can create costly downtime. If your equipment goes down right as you're getting started, you lose out on valuable work time. Spring maintenance can keep things running smoothly when your work opportunities start to ramp up.

- Protecting your equipment: If you live in an environment where winter temperatures frequently reach dangerously low temperatures, your vehicle can be at certain risks that you need to address come spring. The metal can contract and expand or change shape, causing cracks and becoming brittle, while seals can break and fluids can freeze. Winterizing is an important component of vehicle prep that can minimize the damage from extremely cold temperatures with a few preventative measures.

- Repairing damage: Most heavy equipment is too large to be conveniently stored indoors during the winter, so you have to keep them outside. Preparing your heavy equipment for spring can help you address any damage that occurred from the cold. Ice and hail can damage the exterior, while the cold can cause cracking and other problems with seals and fluids.

- Improving safety: Poor maintenance can lead to safety issues such as fire hazards or operating malfunctions. Ensuring your machine is working as well at the end of winter as it did at the start can keep you and your employees safer.

- Protecting your investment: Finally, your equipment is a big investment. If you continue to use it without fixing problems and addressing maintenance needs, you can further damage your machinery, necessitating expensive repairs down the road. If your machinery is vital to your work — as it often is — losing it or waiting for a major repair job to finish can be a massive burden on your work and income. Keep these essential tools safe with proper spring cleaning.

Some pieces of equipment will have an easier time adjusting to the spring weather. For example, tracked vehicles can handle slush and wet conditions much more easily than their wheeled counterparts. Tires tend to dig into the ground, sinking the vehicle and trapping it in the mud.

Another condition that can make spring easier on machinery is keeping it indoors. Of course, not every operation is going to have that luxury, and some vehicles are too large to be store inside. In those instances, winterizing your machine is especially important.

How to Ready Your Equipment

Preparing your heavy equipment for spring is going to vary slightly from industry to industry and vehicle to vehicle, but the process still covers similar aspects. You'll need to perform routine maintenance tasks and keep an inventory of your equipment. It's also a great time to perform other housekeeping tasks, so you're ready for the busy season. By getting all of this work out of the way, you can be better prepared to dive in when the warm weather hits.

Here are some tips for preparing your equipment for Spring:

1. Perform Maintenance Tasks

Spring is an excellent time to conduct periodic maintenance. You can do damage control on components that might have struggled over the winter and make sure your machine is as ready as possible. Some of the maintenance tasks you'll want to complete are:

- Change filters: If your filters get clogged or dirty, they can reduce efficiency and increase contaminants in your system. Change your filters as needed or clean them where applicable.

- Change hydraulic and engine oil: Replace both hydraulic and engine oils during springtime to ensure clean and efficient system operation. Check with your manual to ensure you're using the right type.

- Check coolant: Run the engine and inspect the appearance of your coolant. Make sure it is free of impurities and reflects its as-new color. Since temperatures can still get low in the spring, make sure you get the appropriate grade of coolant for your area's weather.

- Grease components: Lubricate any major components as needed.

- Clean the exterior: Remove snow and ice with a broom or air compressor. Don't use anything that could damage the paint, like a shovel. Do not operate it until you've thawed any ice around the transmission, motor or swinging mechanism. You'll also want to clean off the undercarriage of your machine, removing any debris. Check the tracks for loose pads or inappropriate tension.

- Clean the interior: Give the cab a good cleaning — and replace the air filters. Cleaning the interior can make operation more comfortable for the driver and protect sensitive electronics.

As you work on your machinery, make sure you're keeping track of the tasks you're doing. Update your maintenance logs or start keeping records, if you don't already. Your maintenance log keeps a detailed report of technical information about your machine and the steps you take to keep it in good condition. Some of the things you should jot down include the:

- Serial number

- Model number

- Hours in service

- Filter type

- Oil grade

- Part identifiers

- Dates of oil changes

- Dates of greasing parts

- Repair history

For larger operations, you can also use this time to check your inventory. Is anything aging that may need a replacement, or are there additions you may want? Do you see a repair or other issue in your near future?

2. Check Your Paperwork

Spring cleaning is also an excellent time to check on your paperwork. Dig out your filing cabinet or the folders on your computer and take a look at the following:

- Licensure: Make sure your professional licenses are up-to-date or take note if they will be expiring within the year. You may need to start work on renewing your licensure or continuing education requirements.

- Warranty requirements: Most machinery requires you to take certain measures each year to stay under warranty. Review the terms of your warranty and make sure you abide by them. It may be worth making a schedule and chart if you'll need to do these tasks more than once throughout the year. In addition to keeping your warranty active, the maintenance can keep your machine moving more efficiently.

- Insurance policy: You may not need to do this every single year, especially if your business doesn't fluctuate much, but don't neglect it over time. Confirm your current collection of tools and your scope of work are covered under your policy.

These are the kinds of tasks you do not want to forget about, so it's a good idea to check in on them once a year. Since you're already working on spring cleaning, you can get these done now. Another good time to do them is in the winter when jobs are low.

3. Winterize Your Equipment

While spring cleaning is a significant task on its own, another way to ease the process is by winterizing your machines beforehand. If you get your vehicles ready for the cold and ice in the fall, you can help it better stand up to the elements over the winter months. Whether you use your vehicles during winter or hunker down and wait for the sunshine, you can save yourself an expensive repair by getting ready beforehand.

Some of the tasks you can do to winterize your heavy machinery include:

- Cleaning: Even though you'll want to do this again in the spring, giving your equipment a good scrub can remove any residue that might harden over winter. It could become difficult to remove when the snow melts and gets caked onto your machine. Consider using a pressure washer for some of the harder-to-remove grime.

- Removing water: Remember that water expands as it freezes, so you'll want to drain any components that use it, like a water trap for fuel. This removal includes any fluids that use water in diluted mixtures. Another way to address freezing is to use antifreeze where applicable. Make sure you pay attention to the freeze point, and that you get the right grade for your climate. The freeze point refers to the temperature at which the antifreeze will start to turn to ice or slush. Different levels of solution mixtures allow for a lower freezing point. For example, a 90/10 water-antifreeze solution will only protect you to about 26 degrees Fahrenheit, while a 60/40 mixture keeps it safe down to around negative 55 degrees Fahrenheit. Antifreeze is necessary to keep components from bursting with expanding ice.

- Filling fuel and hydraulic oil tanks: Topping off these tanks helps you to reduce condensation that could freeze. You may also want to add a stabilizer and run the machine for a bit, so it all gets evenly distributed.

- Setting rodent traps: As your equipment sits idle for months at a time, mice and other critters can see it as a great nesting spot. They may set up shop inside your excavator or chew on the wires of your skid steer. This can be very damaging to the equipment as a whole. Consider adding rodent traps in or around your machinery. But make sure to put them only in rodent-accessible places, so any farm dogs or cats won't get sick or hurt themselves on your traps.

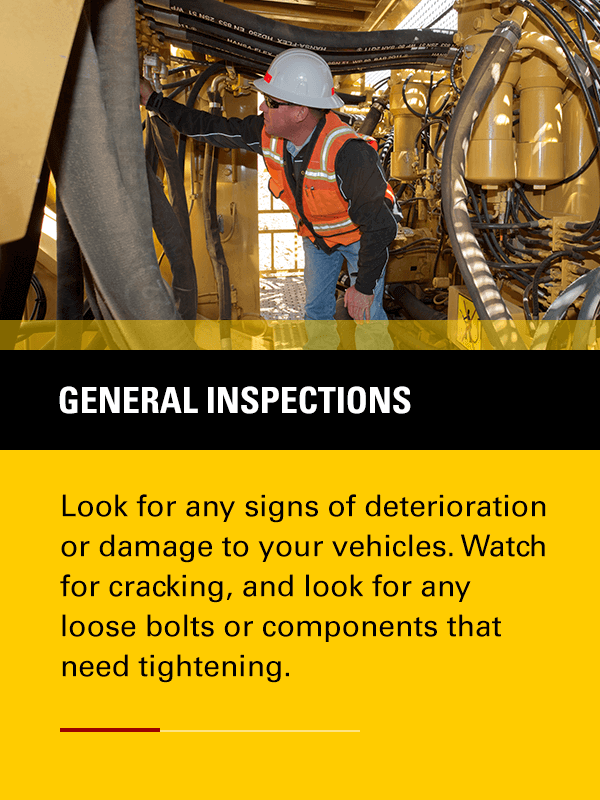

- Performing general inspections: Look for any signs of deterioration or damage to your vehicles. Sun exposure from the summer can wear some non-metal parts, like plastic tanks and rubber hoses, making them less sturdy. Watch for cracking, and look for any loose bolts or components that need tightening.

When winterizing your vehicle, be sure to remove the battery. It can continue to drain even if your machine is turned off. Do an inspection, cleaning the cables and connections and looking for any signs of corrosion. Then, you'll want to store it in a heated location with a full charge.

If you don't take care of your vehicle's battery, you risk the possibility of it freezing. The electrolyte solution in a battery includes a high percentage of water, and as the battery is discharged, the percentage of water increases. So if it freezes, it can expand and damage the battery. It could crack the housing or pose a risk by releasing acid. Keeping the battery fully charged can bring the freezing point down from 32 to negative 76 degrees Fahrenheit, giving you much more leeway in the colder months.

One approach that you may find useful is using a trickle charger. Trickle chargers provide your battery with a small amount of charge to keep it topped off throughout long-term storage. Even when not in use, batteries lose a small amount of power each day. If you do use a trickle charger, you'll still want to keep the battery in a room that is above freezing.

What to Check Before Start-Up

After you've finished your maintenance, it's time for an overall inspection — this step will help you ensure no new surprises have appeared over the winter, like broken wires or leaks. Even without regular use, the elements can take their toll on a stationary piece of equipment.

Here's a list of what to check before starting heavy equipment this spring:

- Lights, flashers and wipers: Basic movement and sight are necessary components of getting your machine where it needs to be. Whether you're driving across the open road or just through a field or job site, check that your lights, flashers and wipers are working. You may also want to take a look at things like the windows and air conditioning.

- Brakes: Of course, you'll need working brakes. Test them out and make sure they're working properly.

- Engine belt: Depending on the piece of equipment, you may have one or more belts in your engine, such as a serpentine or V-belt. Inspect these belts closely for signs of wear, like cracking and fraying. Also, check its alignment to ensure it hasn't come loose. You should also check on pulleys and idlers, making sure they are in good condition.

- Hoses: Many pieces of equipment have hoses that carry oil or other chemicals throughout the system. These can become environmental hazards if you allow them to break, releasing contents into the earth or water supply. On farms, pesticides are a significant concern here. Inspect your hoses and replace them if you spot any signs of wear. Sunlight and heat can cause significant damage to rubber surfaces, shown by cracking or swelling on the exterior. Abrasion is another concern — look for areas where the hose can rub up against another component, such as a bolt or joint. If the component has started to wear out the hose, try placing a protector in between them to keep the hose safe. Also, ensure the hose is free of any kinks.

- Clamps: Many components like hoses and piping are held down by clamps. These are usually metal and can suffer wear and corrosion. They may rust or corrode from contact with chemicals. Replace them as needed, but be careful not to over-tighten them and put undue stress on the components they're holding.

- Seals: Check on all of your seals and make sure they're still working at full capacity. Any leaks could reduce efficiency, damage your equipment or pose a health hazard. Make sure seals are still functioning and replace any that are worn.

- Tires: Tire pressure can have a substantial impact on your machine and your work, especially in landscaping and construction. It can influence the drive and the likelihood of leaving marks behind or compacting the soil. Plus, accurate tire pressure can save you on fuel consumption. Check your equipment manual for the appropriate tire pressures for your job and adjust your wheels appropriately. You'll also want to take a look at the tread wear on your tires and make sure they aren't becoming bald. Finally, take a look at the rims as well, ensuring lug nuts are all properly tightened.

- Boom and arm: Check out the parts of your equipment like the boom, arm and attachments. See if any pins or bushings are experiencing wear, and look for damage to lines.

- Battery: Before you put the battery back in the vehicle, take a look at the compartment to ensure it is clean and free of corrosion or foreign materials. You can also check the electrolyte levels and top off the charge.

- Stickers and decals: Over time, the stickers on your vehicle that warn others of hazards can come off or deteriorate. Check that all your stickers are in good condition — they'll help you better communicate hazards, especially on the road, such as a vehicle that moves slowly or takes wide right turns.

Rent Heavy Equipment in the Spring at The Cat® Rental Store

Spring maintenance is an essential part of construction equipment ownership. If it sounds like a bit much to take on, you can also rent your equipment. When you rent heavy machinery, we take care of the maintenance tasks, so you can get straight to work. Alternatively, if a job comes up before you've had the opportunity to get your vehicle ready, a short-term rental can get you moving without delay. Whether you need a short or long-term rental, The Cat® Rental Store has you covered. We also offer purchase options, so you can hang onto your equipment all year long.

With over 1,300 locations across the globe and a wide range of Cat products, we've been helping construction workers, contractors and more get back in the groove of warm-weather work for years. Check out our equipment offerings or find a location near you to get started with The Cat Rental Store.

Find The Cat Rental Store Near You