10 Ways to Reduce Construction Operating Costs

A primary way of measuring your construction company's success comes down to simple math — your revenue minus the costs to produce that revenue equals your profit. The complexity comes in determining the best ways to cut costs to increase profits. Controlling costs is key to helping you improve your company's profitability, which is why we're sharing 10 tips construction businesses can use to get costs down without sacrificing quality.

Jump to a section:

- Track Costs and Pinpoint Trouble Spots

- Train Employees to Reduce Errors

- Improve Job Site Safety

- Incentivize Efficient Work and Innovation

- Go Paperless

- Outsource When It Makes Sense

- Comparison Shop For Materials

- Find Ways to Cut Fuel Costs

- Practice Preventive Maintenance

- Rent Equipment You Don't Need to Own

1. Track Costs and Pinpoint Trouble Spots

To effectively reduce your operating costs, you first need to know where there is inefficiency or unnecessarily high costs in your operations. Trying to cut costs without first pinpointing issues may result in cutting corners if you're not careful. Instead, look for areas where costs are higher than they need to be.

To do this, you need to accurately track and record your overhead costs and the costs associated with particular projects:

- Overhead costs: Consider analyzing your spending quarterly, biannually or annually. Use this information to budget accurately for the future and look for costs you may be able to reduce in the coming period.

- Project costs: When you finish a project, analyze whether any of your costs exceeded your estimates. If so, try to determine the cause of that higher cost. Can you attribute the higher cost to a problem you can solve or improve on before the next project? Since longer project timelines are also associated with higher costs, be sure to look for portions of the project that took longer than planned and see whether there is a way you can avoid that scenario on your next project.

Whatever you find out, create an action plan so you're prepared to address problem areas. Where there is waste, look for ways to eliminate that waste.

2. Train Employees to Reduce Errors

The construction industry as a whole has felt the effects of an ongoing shortage of skilled labor. In some cases, construction companies must hire unskilled workers and help them learn on the job. In other cases, an employee may be skilled in a certain construction-related trade, but they may need to learn new skills to diversify their areas of expertise. Having the necessary skills is key to preventing avoidable errors.

Errors on a project may require reworking, which increases the time and cost to complete the project. One study looked at hundreds of construction projects and found that the direct costs associated with rework made up about 5% of the total cost on many projects. Some estimates put that percentage even higher. It's clear that if you want to reduce construction costs, one smart way to do it is by reducing errors.

There are multiple approaches you can take to preventing errors, including providing more oversight on a job. A good strategy all construction companies should consider is training their employees to improve and broaden their skill sets. Rather than having a worker try something for the first time on a job and make a costly mistake, work through tasks in a training environment so your crew is better prepared to take on unfamiliar tasks and get them right the first time.

When errors do occur, use these instances as learning opportunities so a worker is less likely to repeat the error in the future.

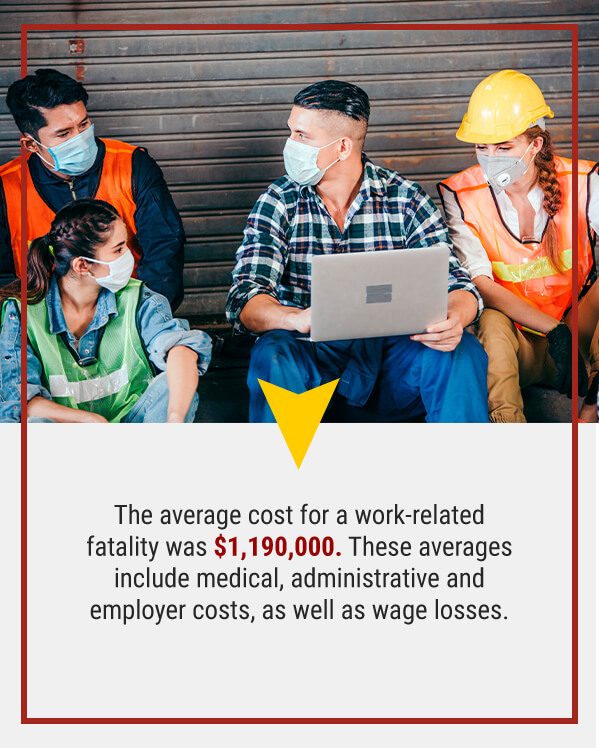

3. Improve Job Site Safety

Safety incidents aren't a standard part of a construction company's operating costs, but they can cost a company significantly. According to the National Safety Council, in 2018 the average cost for a work-related injury that merited medical intervention was $41,000. The average cost for a work-related fatality was $1,190,000. These averages include medical, administrative and employer costs, as well as wage losses.

Employers should also consider the potential costs of fines from the Occupational Safety and Health Administration (OSHA) if an injury was due to a lack of safety on the job site. OSHA penalties can be up to $134,937 per violation in cases where there is a pattern of negligence. An investigation that takes place because a worker was injured may also uncover unrelated safety issues that lead to additional citations.

You can expect to pay higher insurance rates if your company has a history of workplace injuries. Insurance companies have a vested interest in your workers staying safe on the job. You can use that interest to your advantage by asking your insurance company to help you find ways to improve safety so you can both save money on workers' compensation. At the very least, make sure you're abiding by all relevant OSHA standards to avoid hazards.

Improving job site safety may involve taking the following measures and more:

- Conducting frequent site inspections to identify hazards

- Investing in more or better personal protective equipment (PPE)

- Posting warning signs where needed

- Installing guardrails or other types of barriers to prevent falls

- Ensuring only trained personnel operate certain types of equipment

Making job sites safer places is a win-win for workers and employers. It can help workers feel safer on the job, improving employee morale and retention, and it can help construction companies cut costs associated with safety incidents.

4. Incentivize Efficient Work and Innovation

A 2019 study found that employees will be more engaged and productive when they feel valued and listened to. This is important since engaged, productive employees will work more efficiently, cutting down on operating costs.

First, it's important to understand that many employees do not feel heard and valued. This is especially true of "deskless" workers, which would include construction personnel. According to the study, just 37% of deskless workers feel their employers care about their opinions, and only 43% of deskless workers feel their employers are invested in improving the employee experience.

Clearly, there's room for improvement for most companies when it comes to making workers feel like valued contributors. One strategy construction companies may consider to reward efficient work is offering a more moderate pay rate along with plenty of opportunities for performance-based bonuses.

Being open to suggestions and feedback from workers can also encourage workers to be more engaged and productive on the job. This openness can also lead to direct financial benefits if workers have ideas for ways to cut costs. Let workers know your company welcomes their innovative ideas for keeping costs down on projects. You can even reward employees who help cut costs with benefits like extra time off or a cash bonus.

5. Go Paperless

As of 2016, construction was identified as one of the least digitized industries, second only to agriculture and hunting. Many construction companies still print files to share and store them rather than keeping things digital. If this is true of your company, consider going paperless wherever you can. This move is more environmentally responsible and will save you money in the long run.

Printing invoices, for instance, may not seem very costly at the time, but these print jobs can add up significantly. Even if you still want to give clients the option to receive a hard copy of their invoice, see whether they would be OK with a digital invoice before printing. Sharing files digitally can also save you from postage costs.

One of the most costly print jobs for many construction companies is producing blueprints. That's because blueprints are large enough that they require large-format printers you likely only find at a commercial print shop. If you haven't gone digital with your blueprints, consider this option as a way to save paper and costs over time.

Going paperless may also mean replacing some traditional methods of planning, bookkeeping and other tasks with software to help you complete those tasks digitally. Software may cost more than paper and ink initially, but software programs can help you save by improving the accuracy and efficiency of your operations. You can find software programs tailored to helping construction companies with a whole host of areas, including takeoff, project management, reporting, fleet management, collaboration and much more.

6. Outsource When It Makes Sense

Some construction companies can save on operating costs by outsourcing certain operations to third-party providers. In some cases, it's more efficient to have an employee handle a particular aspect of your operations. In other cases, handling something in-house may end up costing you more in overhead than outsourcing to a company that already has the skills, qualifications and tools needed to get the job done expertly and efficiently.

Choosing not to outsource may seem like the more affordable option, but it could end up costing you if the employees handling the task lack the necessary qualifications to be error-free and efficient. You may end up spending more in training your employees or running into issues involved with learning curves than you would spend to have an expert handle the task.

The key is to determine which aspects of your operations you may be better off outsourcing. The answer will differ from company to company. For each aspect of your company's operation, do a price comparison to see what would be the more cost-effective solution. Some examples of tasks construction companies may choose to outsource include:

- Employee training

- Background checks for prospective hires

- Information technology (IT)

- Accounting

- Takeoff and estimating

- Subcontractor screening

- Legal compliance

- Permit expedition

Another aspect of outsourcing is knowing when to bring in subcontractors for particular tasks. It's important for contractors to know their limits and identify when they should hire an expert in a particular trade so they can maintain a high standard of quality on a project and maximize profits.

7. Comparison Shop for Materials

Material costs can make up a significant portion of construction operating costs, so it makes sense to take a close look at your material spending. Construction companies often form long-term relationships with suppliers or distributors, going straight to that company each time they need to source materials. In some cases, contractors do this because their customer loyalty has earned them discounts. Discounts can be a great perk of working with the same suppliers or distributors. However, even when you're getting a discount, that doesn't always mean you're getting the best deal.

Instead of sticking to the same suppliers, consider buying dynamically. Compare prices from different sellers to see whether it makes sense to switch suppliers or to source some materials from one seller and other materials from another — even if you could get all those materials from one seller. In their article on helping homebuilders cut construction costs, BUILD magazine recommends companies reevaluate where they should purchase materials with every project or at least every few months.

This ongoing comparison shopping can help you get the best deal and may even encourage your long-standing sellers to offer you more competitive discounts to keep your business. It's also worth noting that contractors can save on material costs by buying in bulk, but this practice is a bit risky if you aren't sure whether you will need materials in the future.

Bulk buying will likely make more sense for basic raw materials you are sure to use versus a particular style of flooring, tile or other materials that are subject to an owner's preference. For any materials you do buy in bulk, you'll have to store them properly to ensure they remain in good condition. Storage costs can also influence whether bulk buying saves you money or not in the long run.

8. Find Ways to Cut Fuel Costs

Construction equipment can consume a lot of fuel, so finding ways to lower fuel consumption and pay less for fuel is a smart move for any construction company. As with materials, compare suppliers to see which energy supplier and pricing plan will get you the best deal.

In some cases, improving fuel economy will also mean upgrading equipment. Generally, older equipment can cost companies more to operate since it isn't designed to be as energy-efficient as newer models. If you have equipment, such as generators, on-road vehicles or heavy machinery, that is known to be a gas guzzler, it may be time to replace it. When shopping for new equipment, look for models that are designed for peak energy efficiency.

Energy efficiency comes down to a piece of equipment's operation as well as its design. Practices like unnecessary engine idling or sudden breaking can contribute to higher fuel costs. If you don't already have technology in place to monitor fuel usage, consider investing in this technology so you can identify issues that are leading to excessive fuel consumption — whether that issue originates with the equipment or with the driver.

GPS tracking systems may also encourage drivers to operate equipment more carefully since this tracking provides some accountability. This means you can save on fuel costs and potentially on safety incidents and insurance premiums. You may also want to train equipment operators or drivers on best practices for reducing fuel consumption and for extending the life of equipment.

9. Practice Preventive Maintenance

When looking for ways to reduce construction costs, it may be tempting to cut down on preventive maintenance tasks. However, a lack of preventive maintenance can lead to increased costs when equipment breaks down, causing unplanned downtime. Experts estimate that rates of unplanned downtime occurrence can range from 20%-30% of total operating time for many construction companies. A leading cause of this high percentage is an insufficient preventive maintenance plan.

To translate that percentage into a dollar amount, a company with 50 pieces of equipment could lose $2 million a year in costs associated with unplanned downtime. These costs include schedule disruptions and renting replacement equipment. Purchasing equipment can easily lead to financial losses rather than a return on your investment if you don't keep the equipment well maintained. Equipment malfunctions or shutdowns can also cause a safety risk on a job site, which has its own costs.

Each piece of equipment has its own maintenance needs, so consult the manufacturer's specifications and owner's manual to determine what maintenance tasks to complete and how often. Keep a schedule or checklist you can use to ensure these tasks are completed. You should also inspect equipment periodically to look for any signs of wear or problems that may need to be addressed.

The relatively small, ongoing expense of preventive maintenance is a smart investment since it can save you from much higher costs associated with equipment breakdowns.

10. Rent Equipment You Don't Need to Own

Purchasing equipment is a major investment. You have to consider the sticker price and the ongoing cost to maintain, insure and store that equipment. Buying equipment makes sense when you'll use that equipment consistently across projects. Over time, you'll see a return on your investment if you use the equipment frequently enough. In some cases, you can experience significant financial savings by renting instead of buying equipment.

Let's look at some reasons why renting can be more cost-effective. When you rent, you can:

- Forgo making a major financial commitment: Renting lets you pay a more affordable fee for the time you're using the equipment rather than having to make a large down payment and continued payments on the equipment, whether you're using it or not.

- Save on maintenance and repairs: Maintenance can be a major cost associated with equipment ownership. When you rent, you don't bear the responsibility for maintenance. Instead, it's up to the dealer to cover preventive maintenance and repairs.

- Maximize your profitability with the right equipment: When you're limited to the equipment you own, you may have to turn down certain jobs or spend more time on a task you could complete more efficiently with a different tool. Renting lets you diversify your fleet so you always have the right tool for the job.

- Avoid storage and transportation costs: Safely and securely storing equipment is another ongoing cost you have to factor in when you own equipment. Transporting equipment to a job site can add to your costs. By renting equipment from a dealer near the job, you can minimize both of these costs.

- Stop worrying about depreciation: As with any big investment, when you purchase construction equipment, you may worry about the change in value over time. When you rent equipment, you don't have to worry about issues of depreciation, market changes or resale.

Rent the Equipment You Need From The Cat® Rental Store

If you're looking to rent equipment to cut down on costs and ensure you have the right equipment for every job, look to The Cat® Rental Store. We're a trusted source for high-quality rental equipment from Caterpillar and other reputable brands. Our dealers offer affordable rental prices on their wide selection of equipment, tools and accessories. Browse the rental equipment catalog to save time and money on your next job with the right rental equipment.

Find The Cat Rental Store Near You