Road Construction Work Safety Tips

Like it or not, road construction is a frequent and frustrating experience for many drivers. But what about the workers who put their lives at risk every day? Between the years of 2003 and 2017, an average of 123 workers lost their lives at road construction sites each year. In addition to the normal risks associated with a construction site, road construction zones also have to contend with high-speed vehicles in close proximity, heavy machinery and environmental hazards. Making the workplace safe suddenly becomes a lot more complicated.

Thankfully, there are steps you can take to minimize the risk of your workers becoming a part of that number. With proper safety precautions, work behaviors, appropriate PPE and more, you can better protect them from the dangers of the work zone. We've compiled a list of tips for road construction site safety, to help your workers stay safe in road construction work zones.

Jump to a section:

Common Causes of Road Construction Injuries

Most drivers are well aware of the level of care that goes into promoting safe driving practices near road work locations. Between the bright signs and the warnings declaring the consequences of striking a worker, you might think that this is the most prominent hazard facing construction laborers. After all, these cars are driving at high speeds and can do some serious damage. While collision from traffic is still a significant and dangerous threat, another pressing concern at roadwork sites is struck-by accidents with other construction vehicles and mobile equipment. Between the two dangers, over half of all fatal injuries at road construction sites between 2011 and 2016 involved pedestrian- vehicular incidents.

Of these incidents, almost a quarter involved trucks, followed by multi-purpose highway vehicles like pick-up trucks and SUVs and passenger vehicles. Dump trucks were the cause of nearly half of the fatalities from all truck types.

While general construction laborers saw the highest number of fatalities, crossing guards experience the highest risk, with 40.9 deaths per 100,000 full-time equivalent workers (FTEs). The rate for the construction industry as a whole is only 0.9. This crossing guard or flagger position involves those who stand close to high-speed vehicles where visibility and conditions can significantly affect a driver's ability to see the worker and increase the worker's risk of injury. Another position with high risk is paving and surfacing equipment operators.

Conditions that can increase the risk for roadside workers include:

- Bad weather, which can cause icy and slick roads, fog, heavy rain and high winds

- Low visibility, including nighttime, snow, fog and mist

- Tight workspaces, which can increase worker proximity to hazards

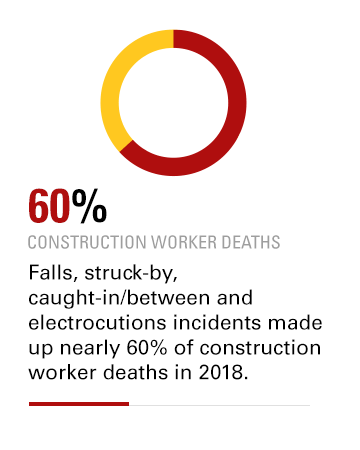

In the construction industry, there are four major hazards identified by the Occupational Safety and Health Administration (OSHA). Combined, these Fatal Four hazards made up nearly 60% of construction worker deaths in 2018. While falls are the biggest culprit, struck-by incidents came in at 11.1%. The hazards are as follows:

- Falls: Workers can fall long distances from areas like unprotected sides and holes, inadequate walking/working surfaces and improperly worn personal protective equipment (PPE). Appropriate fall arrest systems, perimeter protection and safe work procedures can help prevent them.

- Struck-by: These incidents are more common on road construction sites and include vehicle and equipment strikes as well as equipment overturning, a rigging failure or loose materials. To avoid these incidents, workers need to maintain awareness of their surroundings and wear their high-visibility clothing, like vests and hardhats.

- Caught-in/between: This category of hazard also includes equipment rollovers, along with dangers from excavation collapses or improperly guarded parts. Minimizing caught-in/between injuries involves maintaining appropriately guarded excavation protection systems and equipment.

- Electrocutions: Electrical injury can occur from contact with power sources like overhead power lines, live circuits and damaged cords. A watchful eye is crucial in preventing electrocution. Identify utility lines and possible hazards and maintain safe distances from them. Ensure workers do not use tools without appropriate electrical safety features that are in good condition.

Ensure your workers are well-aware of these threats and arm them with the equipment to protect themselves. We'll go over how to stay safe in road construction work zones in the next section.

Road Work Zone Safety Tips

Every element of the jobsite, from entering it to driving heavy machinery throughout, can be risky if workers don't know what to look for or how to use their tools properly. Here are some worker safety tips for road construction work, along with administrative tasks that can help make the work zone safer.

1. Behavior

One of the most fundamental approaches to safety is to instill safe behaviors in your workers. Informing them of the dangers and how to appropriately respond to risks can help drill in these ideas:

- Be observant: Workers should be alert at all times, especially around moving vehicles. Before changing positions or starting a new task, they need to look around carefully for any potential hazards or nearby equipment. Blind spots can be difficult for vehicle operators to overcome, so it is up to every worker onsite to watch out.

- Understand communication signals: All workers, whether on foot or in the cab of a machine, need to be on the same page. They must know their communication signals and use them generously, so others are aware of the goings-on of the worksite. Sufficient training can help improve the use and knowledge of these signals.

- Foster an environment of responsibility: Everyone at a site shares responsibility for the safety of their coworkers and themselves. From supervisors to laborers to machine operators, each person can cause serious injury if they do not abide by safety rules and behave responsibly. Encourage this kind of behavior with everyone on your construction site.

2. Vehicles

Remember that motor vehicles, from both traffic and construction equipment, are one of the most prominent dangers to construction workers on the highways. Follow appropriate safety procedures to help keep their hazards to a minimum:

- Use the parking brakes: Whenever your vehicle is not in use, keep the parking brakes on. If parked on a hill or incline, place blocks in front of or behind the tires.

- Wear seat belts: Even if the equipment is only moving at low speeds, seat belts are a necessity. Massive weights in the event of a tip-over and the danger of nearby high-speed vehicles can make even small collisions dangerous. Require seat belts at all times.

- Maintain awareness around moving equipment: Always be careful when approaching machinery, whether in motion or not. Do not do so without signaling to the operator your intent and getting a response in return. Do not stand directly in front of or behind a moving vehicle, either, as it can be difficult for the operator to see you around equipment and blind spots.

- Acknowledge people on the ground: Similarly, vehicle operators need to acknowledge the workers around them. They should not move the equipment without making eye contact with nearby workers on foot.

- Don't ride on equipment: If the machine is in motion, do not ride on it. Keep a safe distance from any moving parts.

3. General Safety

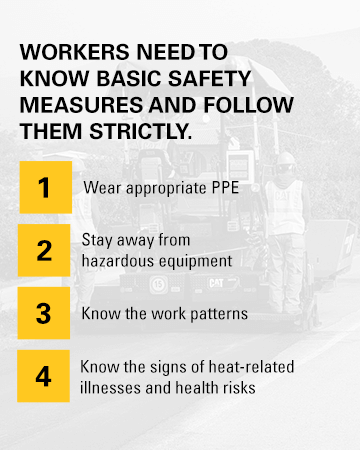

Understanding your surroundings is vital in a construction environment. Workers need to know basic safety measures and follow them strictly. Some that are particularly prevalent in roadside construction include the following:

- Wear appropriate PPE: We'll go over PPE more in the next section, but workers must wear their PPE at all times and according to the task at hand. High-visibility clothing is typically required at all times, along with hardhats and steel-toed boots. Some gear, like respirators and hearing protection, is only needed if the environment requires it. For instance, working with heavy dust or loud tools would necessitate these. High-visibility apparel is crucial in a construction site, especially in low light. Also, workers shouldn't wear any loose-fitting clothes that could become caught in nearby machinery.

- Stay away from hazardous equipment: Know what distances are safe and which ones could be dangerous. Never stand under suspended equipment such as buckets and booms. All workers should know what a safe distance looks like and maintain it wherever heavy machinery is in place. If working near power lines, make sure you understand the minimum distance that workers and machinery should maintain.

- Know the work patterns: Workers should have a good grasp of the construction site. That includes knowing channel lanes and entry and exit points for vehicles, as well as areas where walking is off-limits.

- Know the signs of heat-related illnesses and health risks: Particularly in the hottest months where road construction is at its peak, heatstroke, sunburn and dehydration can be major problems for workers. Employees should know the signs and symptoms and be on alert, not just for themselves but for their coworkers as well. Staying hydrated and wearing light clothing, sunglasses and sunscreen can help combat some of the effects of the heat and sunlight.

4. Specific Roles

While everyone is responsible for the general safety of a construction zone, certain people have specific safety-related tasks to perform:

- Supervisors: In a role with authority, the supervisor needs to ensure workers are engaging in safe behaviors. This means they must wear their PPE, stay clear of hazards and operate vehicles appropriately. The supervisor can heavily influence whether or not safety measures are in place on a worksite.

- Flaggers: People with this role must constantly be on alert, with a robust knowledge of the traffic flow and work zone. They should also ensure all traffic channeling devices are in the right spots. They will be in a risky position in the roadways and need to know where they should be, what accepted hand signals are and to never turn their backs on traffic. They should always be positioned at a distance from other workers so that motorists can identify them more easily. Often, flaggers will use radios to communicate with each other to improve clarity. Flaggers should have the authority to halt operations if a hazard appears and a traffic control supervisor is not immediately present.

- Spotters: On many worksites, spotters are specially designated to watch out for dangerous situations. They need to have a solid understanding of safety requirements and know what signs can indicate an accident. They should also know their hand signals and maintain safe distances.

5. Administrative Tasks

As someone with more control over the worksite, administrative tasks like engineering controls and training methods can help reduce the risks within a construction site:

- Conduct a risk assessment: With the help of standards from organizations like OSHA and the Federal Highway Administration (FHWA), performing a thorough risk assessment can help you identify hazards at the site and address the measures you will take to reduce or eliminate their risks to employees.

- Ensure quality training: Proper training guides your employees on appropriately using large machinery and other aspects of navigating a construction site. Without extensive training, workers can seriously injure themselves or others in any number of ways.

- Maintain your distance from traffic: Try to keep the workers as far away from traffic as possible and make sure your flaggers know where they should safely stand. Flaggers must be easily identifiable as well.

- Create a clear and safe traffic pattern: To ensure vehicles and workers can maneuver around the construction zone safely, you'll need to establish a safe route and mark it clearly. Traffic control measures must be highly visible and abide by all standards so that motorists can identify the work zone and any spotters directing cars.

- Evaluate your vehicle usage: Make sure the vehicle you are using fits the task. Avoid equipment that is unnecessarily fast or powerful, and think about things like the speed of nearby traffic and the character of your work site. Try to use the safest tool possible that will still get the job done.

- Increase visibility: With the number of ways that low light can drastically impact worker safety, adopting measures to increase visibility can help significantly. We've already mentioned high-visibility clothing, but you can also add visibility features into the workspace itself. Place reflective tape on your equipment and set up portable lights as needed, with consideration to avoiding glare that could distract passing motorists. Make use of spotters during periods of low visibility.

- Review your safety barriers: Match the barriers to the requirements of traffic. If it is light, orange cones may be enough, but heavy traffic could call for temporary barriers.

- Know your utilities: Make sure any utility lines are clearly marked, to reduce electrocution risks.

- Monitor the noise level: Check the noise level to see if you need to provide earmuffs or earplugs. Both can help reduce the risk of hearing loss for workers in loud environments. OSHA has certain decibel limits in place before hearing protection is required.

- Provide abundant cooling items: In the hot months, keep workers safe from dehydration and heat stress by making water available, as well as fans and cooling towels. Fluids that help replenish electrolytes are also a good idea.

- Roadwork features: Consider implementing additional features that can improve safety like rumble strips and variable message boards that can help motorists further understand the construction site.

- Provide appropriate PPE: With a thorough understanding of the risks that your workers will be exposed to, you can more accurately select the right PPE. Ensure each piece of equipment is well-suited to the task and the risks at hand.

Safety Standards for Road Construction Sites

Over the years, a collection of organizations have stepped in to make the road work zone a safer place. One of the most significant ones is OSHA, which has plenty of regulations in place for worker safety efforts. OSHA created the PPE requirements and much more.

Another big player in road safety standards is the FHWA. They created the Manual on Uniform Traffic Control Design (MUTCD), which identifies the standards for traffic control mechanisms, required in almost every roadwork site. They also define the needs for high-visibility clothing and gear.

Both of these organizations reference guidelines set by the American National Standards Institute (ANSI). The ANSI develops standards for various industries, products and services throughout the country.

Other useful organizations include the National Institute for Occupational Safety and Health (NIOSH) and the National Highway Work Zone Safety Program (NHWZSP). Both provide more information about traffic control mechanisms, safety practices and more.

1. PPE Requirements

One significant part of OSHA's requirements is their directives for PPE. Personal protective equipment is a critical part of keeping individuals safe on worksites. The categories that OSHA provides regulations for include:

- Eye and face protection: Where foreign objects like dust, shards or chemicals could enter the eye, the worker must wear safety glasses or a face shield. Energized electrical systems also warrant eye protection.

- Foot protection: In construction zones, workers need to wear work shoes or boots with soles that are slip- and puncture-resistant. If working near heavy equipment or any falling objects, they will also need safety-toed footwear, like steel-toed boots.

- Hand protection: Gloves should fit the task at hand. For instance, electrical work requires insulated gloves and sleeves, working with sharp objects requires thick, cut-resistant gloves and welding tasks require welding gloves. There are many more glove types to be used accordingly.

- Head protection: Workers must wear hardhats if objects could fall from above or where they may experience bumps or contact from fixed objects and electrical hazards. If any of these incidents occur, the worker must replace the hat immediately.

- Respiratory protection: Respirators are necessary if a worker could breathe in air contaminated with dust, fumes, vapors, etc. Even though roadwork happens outdoors, high concentrations of fumes, chemicals or dust can make a respirator necessary.

- Fall protection: While heights aren't as common in roadwork as they are in other construction applications, you must still be aware of any fall arrest systems that may be necessary for your work.

In every instance of PPE, workers should be trained on proper usage and how to identify a piece of equipment that needs to be taken out of service. No PPE should be used if it is damaged, worn or could otherwise impede upon the safety of the worker. Also, accurately wearing PPE is necessary for it to work correctly. A hardhat that doesn't fit right could slide off on impact, and a respirator that doesn't have an air-tight seal is one that still allows contaminated air to reach the wearer. Ensure appropriate practices when using PPE for all workers.

Rent Road Construction and Safety Equipment From The Cat® Rental Store

Roadwork construction zones are a particularly dangerous place to be. While we may not yet be able to eliminate the causes of road construction injuries or deaths completely, we can significantly reduce the risks by following strict operating procedures and safety standards for road construction sites.

When it comes to making the road a safer place for motorists and your workers, The Cat® Rental Store has an array of high-quality roadworking tools. We have safety equipment like arrow panels and light towers, along with heavy machinery such as asphalt pavers, road reclaimers and more. In addition to our collection of Cat products, we also have equipment from 70+ OEM providers and excellent customer service. Renting roadwork equipment can offer flexibility and cost savings. Browse our roadwork equipment today and see how The Cat Rental Store can help you make a safer worksite. Rent the tools you need from the people who know what it takes.

Find The Cat Rental Store Near You