Smooth Roller vs. Padfoot Roller: Which Rental Fits Your Project?

Compaction is one of the most important steps in construction. Whether you’re smoothing asphalt or preparing a foundation, the right roller ensures surfaces are dense, stable, and safe. Contractors often rely on compaction equipment rentals because job requirements vary. For some projects, a smooth drum roller rental is ideal; for others, a padfoot roller rental is a better fit. Here is your guide to roller compactors:

What Is a Compaction Roller?

A compaction roller is a machine that uses pressure, vibration, and impact to condense soil, gravel, sand, ballast, rock, or asphalt. Compaction ensures the surface can support structures and prevents settling that leads to cracks or instability.

Rollers are essential for building roads, preparing land for development, compacting backfill for pipelines or underground utilities, and creating stable foundations.

Smooth Drum Rollers

A smooth drum roller features one or two steel drums with smooth surfaces.

- Single drum: One drum in front with rear wheels for traction. Maneuverable and effective for soil compaction.

- Double drum: Drums in front and back for faster coverage. Ideal for asphalt and granular materials.

You can also choose a vibratory roller or look into a tandem vibratory roller for extra compaction power. They are best for asphalt paving, sand and gravel compaction, and leveling land for roads or foundations.

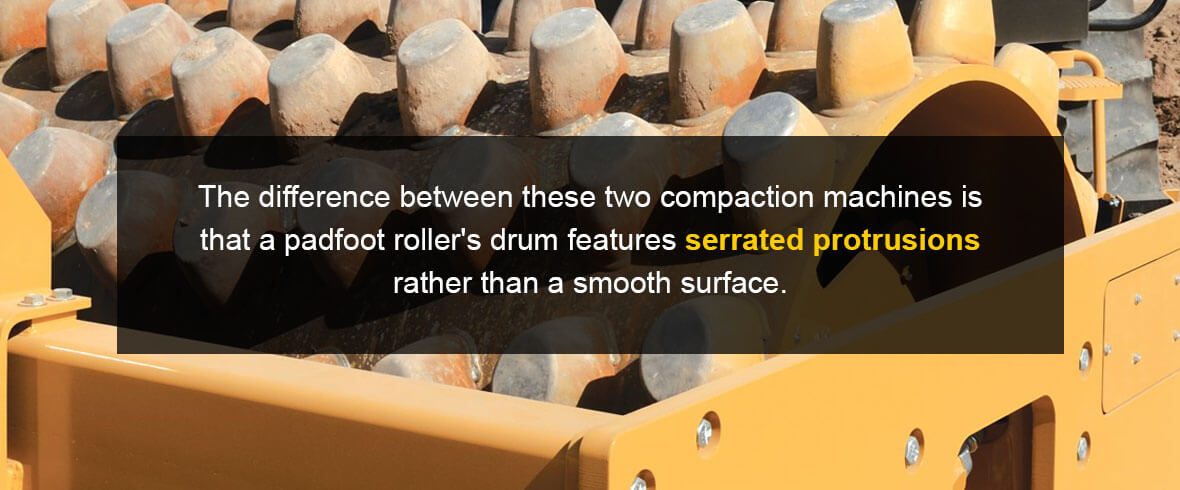

Padfoot Rollers

Padfoot rollers, also called sheepsfoot rollers, feature drums with protruding pads or “feet.” These create a kneading action that compacts material more deeply than smooth rollers. Padfoot rollers can also include leveling blades to push material aside.

Operators can add water or sand to increase drum weight and compaction force.

Best uses:

- Clay or cohesive soils

- Damp or high-moisture environments

- Compaction near bodies of water or in high-water-table conditions

- Utility trench backfill.

Padfoot rollers are less effective on granular materials like sand or gravel because the pads churn instead of compressing them.

Comparing Smooth vs. Padfoot Rollers

- Compaction style: Smooth rollers rely on static pressure and vibration; padfoot rollers knead materials for deep compaction.

- Material compatibility: Smooth rollers work best on granular soils and asphalt; padfoot rollers excel on cohesive, damp soils.

- Coverage: Double-drum smooth rollers compact large areas quickly; padfoot rollers handle heavy-duty, high-density jobs.

- Finish: Smooth rollers leave a flat, level surface ideal for paving; padfoot rollers leave a rougher profile better for structural stability.

Knowing these differences ensures you select the right rental for your jobsite conditions.

Other Compaction Options

Beyond smooth and padfoot rollers, options include:

Pneumatic rollers: With multiple rubber tires, they compact materials evenly and are useful for soft soils or cold mixes.

Plate compactors: Smaller machines with vibrating plates, ideal for confined spaces or small projects.

Rammers: Feature a smaller steel plate. Deliver intense force in narrow areas for trench or backfill compaction.

These additional tools complement rollers, allowing you to handle unique compaction challenges.

How to Choose the Right Roller

Your choice depends on material type and project requirements:

If working in asphalt, sand or gravel, use a smooth drum roller.

If working in clay, cohesive soil, or wet ground, choose a padfoot roller.

If working on large road or foundation projects, then double-drum smooth rollers save time.

If handling utility or water-adjacent projects, padfoot rollers ensure density.

Consider soil type, moisture content, and surface size before renting. The Cat® Rental Store specialists can help match your project to the right machine.

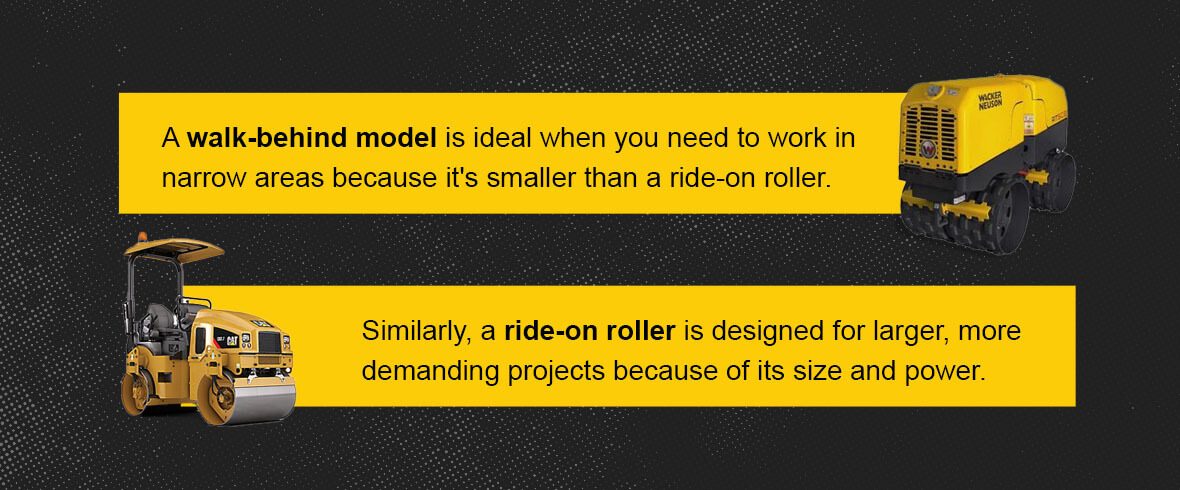

Renting vs. Buying Compaction Rollers

Deciding whether to rent or buy depends on usage frequency. For contractors who need rollers occasionally, renting offers advantages. You’ll have lower upfront costs, reduced maintenance responsibilities, equipment choice flexibility and access to the latest tech.

Why Rent From The Cat® Rental Store?

The Cat Rental Store provides a wide selection of compaction equipment, including smooth drum, padfoot, pneumatic, and plate compactors. Benefits include:

- Flexible rental terms (daily, weekly, monthly)

- Expert consultation to choose the right roller

- Machines inspected and serviced to Cat standards

- 1,300+ global locations for convenience

Find your nearest Cat Rental Store dealer or call 1-800-RENT-CAT to explore compaction equipment rentals tailored to your project.