Types of Stump Grinders: How to Choose the Right One

Tree work rarely stops when the trunk is down. Stumps can attract pests, create trip hazards, and get in the way of new planting or construction. That’s why many crews turn to stump grinders. These specialized machines are built to turn wood into mulch below grade. In this guide, you’ll learn the key types of stump grinders, when to use each one, and how to choose the right Cat® Rental machine for your site and budget. Browse the various stump grinders available to compare sizes and features.

What Is a Stump Grinder and How Does It Work?

A stump grinder is a powered cutting machine that removes tree stumps by chipping wood into small pieces. A rotating cutter sweeps across the stump, shaving it down in layers. By working below the surface, you can reclaim the area for landscaping or building. If you’re new to these machines, start with our quick overview of equipment that removes tree stumps which explains basic operation and safety.

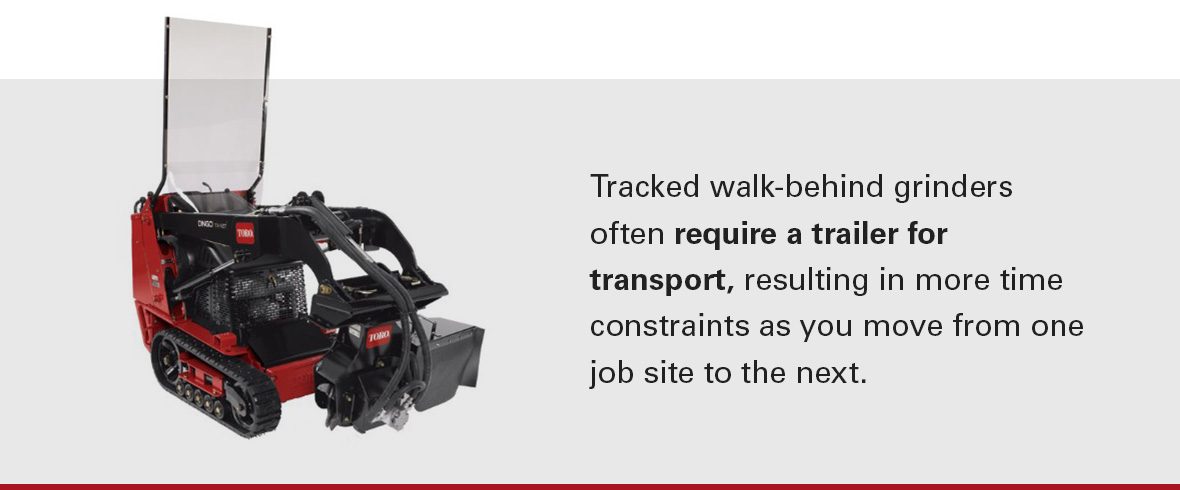

Tracked Walk-Behind Grinders

Tracked walk-behind grinders are larger and built for heavier work. Operators walk behind the machine and use onboard controls to guide the cutting wheel with precision. Tracks spread the weight evenly, which reduces the chance of damaging lawns or landscaped areas. These grinders shine on rough or uneven terrain, making them a solid choice for residential projects or jobs with tight deadlines. The tradeoff is they often need a trailer for transport, which can add time when moving between sites. Still, their power and durability make them dependable for tough conditions and large-scale projects.

Wheeled Handlebar Grinders

Wheeled handlebar grinders are compact, lightweight, and simple to use. Operators guide them by hand with easy-to-reach controls and rely on lift handles for smooth transport. They’re perfect for tight spaces and quick to maneuver, ideal when you’re tackling just a few stumps.

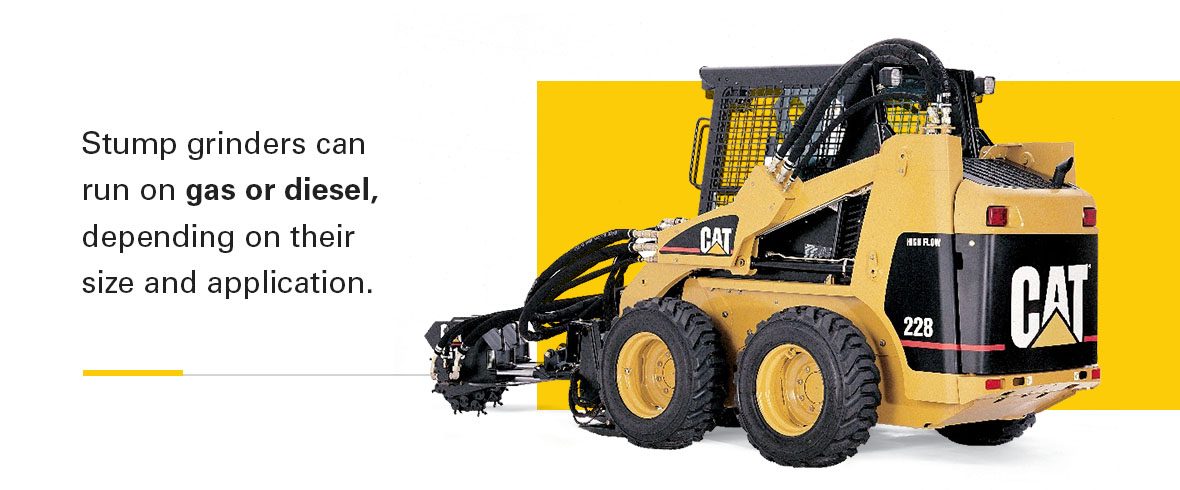

Attachment Grinders

If you already own a skid steer or tracked loader, an attachment grinder can be a cost-effective option. These mount directly to your equipment and operate with the same controls you’d use for buckets or augers. They’re a great choice if you only need stump grinding occasionally since you can attach them when needed and store them when not in use.

Riding Grinders

Ride-on stump grinders are self-propelled machines designed for efficiency on bigger jobs. Instead of pushing or guiding the grinder, you simply drive it from stump to stump. They’re especially useful when you need to clear multiple stumps quickly or manage several projects that require frequent land clearing.

How to Choose the Right Stump Cutter for Your Job

Renting a stump grinder makes sense if you only need to clear stumps every now and then or for a specific project. To get the job done quickly and safely, you’ll need to choose the right type of grinder. Here are the main things to think about before you rent:

- Stump size: The width and height of your stumps will guide your choice. For example, handlebar grinders can struggle with stumps larger than 14 inches. Knowing the limits of each model helps you match the tool to the job.

- Stump hardness: Softer woods are easy to cut, while hardwoods need more power. A wheeled stump grinder is usually best for tougher stumps. Pick a grinder that can handle the type of wood you’re working with.

- Number of stumps: For one or two stumps, a handlebar grinder is often enough. If you’re tackling several, you’ll need heavier-duty equipment that can keep up.

- Terrain type: Rough or uneven ground can be difficult for wheeled grinders. Tracked stump grinders work better on slopes, loose soil, or delicate landscapes like lawns and gardens.

- Stump condition: Old or rotting stumps are easier to grind, which means you can save money with a smaller machine. Healthy, solid stumps need more horsepower.

- Rental companies: Don’t forget who you’re renting from. Look for a company with a good reputation, well-maintained equipment, and service plans. This ensures you have reliable support and machines that are ready to perform.

Safety and Best Practices

Before you grind, mark utilities and inspect the site for rocks, metal, or hidden debris. Stabilize the machine on firm ground and set a safe work zone. Wear eye, ear, hand, and foot protection and avoid loose clothing. Keep bystanders clear of the work area and never reach under the cutter head until the machine is off and the wheel has fully stopped.

Productivity and Restoration Tips

Sharp teeth are everything. Inspect and rotate teeth regularly to keep cutting speed high and vibration low. If sparks appear or dust replaces chips, stop and service the cutter wheel. On dense hardwoods, lighten your passes and let the machine’s weight and hydraulics do the work. Forcing the cut only burns fuel and dulls teeth faster.

Plan your sequence across a site so you minimize travel and repositioning. Stage cleanup tools nearby and use a blower to keep chips from hiding hazards.

Grinding doesn’t remove every root, but it takes the stump down far enough to reclaim the area. Backfill the hole with a mix of soil and chips or haul chips away and import topsoil for planting. Advise owners that chips can settle; a small mound helps prevent a low spot later. If you plan to pour concrete or build, dig out additional material and compact the subgrade to reduce future settlement.

Chips can be reused as mulch or hauled to green‑waste facilities. In residential neighborhoods, plan work during reasonable hours, use machines with sound‑attenuating features when available, and keep the site clean to maintain good relations with neighbors.

Stump Cutter Maintenance

Daily checks keep grinders productive. Inspect belts, hydraulic hoses, guards, and emergency stops before each shift. Grease pivot points and verify cutter wheel hardware torque as recommended by the manufacturer. For transport, use rated ramps, secure tie‑downs at designated points, and chock wheels when loading and unloading.

Cost: Estimating Time and Budget

Time per stump depends on diameter, species, and terrain. As a rough guide, small softwood stumps may take minutes, while large hardwoods can take significantly longer. Factor in site access, chip removal, and any obstacles. When you price a job, include travel, setup, grinding time, tooth wear, and cleanup—then build in a buffer for unknowns like buried rock or metal.

Stump Grinder FAQs

Which stump grinder is best for tight backyards?

Walk‑behind or compact self‑propelled tracked grinders fit narrow gates and delicate lawns while still reaching below grade.

Can I grind a stump next to a fence or wall?

Yes, but go slow and protect nearby structures from flying debris. Excavator attachments help when reach or positioning is limited.

How deep should I grind?

Most jobs call for grinding 6-12 inches below grade. Go deeper if you plan to replant or pour concrete over the area.

How do I know when teeth need replacement?

Watch for slower cutting, more vibration, or fine dust instead of chips. Inspect teeth daily and rotate or replace as needed.

Is renting better than buying?

If you don’t grind weekly, renting is often the smarter choice. You get the right size machine for each job without long‑term maintenance costs.

Get the Right Stump Grinder for Your Next Job

The Cat® Rental Store can help you match stump grinder size and type to your site, schedule, and budget. If you want local guidance or a quick quote, find a store near you, submit a request through contact us or find the Cat Rental store near you to speak with a nearby dealer.