What Is Industrial Construction?

Industrial construction covers large-scale projects like warehouses, factories, and power plants. These buildings are different from commercial spaces such as stores or schools because they need stronger designs, have stricter safety standards, and use heavy-duty equipment. This guide explains what industrial construction is, how it differs from commercial building, and what equipment is used.

What Is Industrial Construction?

Industrial construction focuses on designing and building facilities for manufacturing and distribution. These projects must meet federal, state, and local codes. They also need floor plans that can handle heavy machines and layouts that connect to highways, railroads, or ports. In short, these buildings are designed for function first.

Types of Industrial Buildings

Most industrial projects fall into two categories:

- Warehouses and distribution centers: These huge spaces feature tall ceilings, loading docks, and big parking lots for trucks.

- Manufacturing plants: Also called heavy industrial buildings, these facilities house large machines. They need a reliable power supply, good ventilation, and systems for pressurized water or air.

How Is Industrial Different From Commercial Construction?

While both build structures, the goals and methods are different:

- Site planning: Commercial projects focus on easy customer access. Industrial projects focus on transport routes for shipping.

- Design: Commercial buildings often care about looks. Industrial buildings care about safety and efficiency.

- Infrastructure: Commercial sites need basic utilities. Industrial sites need systems strong enough for large-scale machines.

- Project management: Industrial projects require more specialized skills, parts, and coordination.

- Final steps: Commercial projects mostly need local approval. Industrial projects must also meet strict state and federal standards.

What Makes a Good Industrial Construction Company?

Because these jobs are complex, not every contractor is suited for them. Strong industrial construction companies usually share three traits:

- Skilled teams: Specialists in planning, design, and project management

- Experience: A track record of building factories, warehouses, and plants

- Innovation: Use of modern methods like prefabrication to save time and money

Equipment Needed for Industrial Construction

Heavy equipment is central to industrial projects. Machines prepare the site, move materials, and handle lifting and transport. Some types of equipment are used across industries; others are specific to industrial construction.

Transportation Equipment

- Articulated trucks: Haul dirt and debris across rough sites.

- Dump trucks: Carry and unload loose materials.

- Off-highway trucks: Used on large projects to haul big loads on-site.

- Utility trailers: Tow tools, supplies, and equipment.

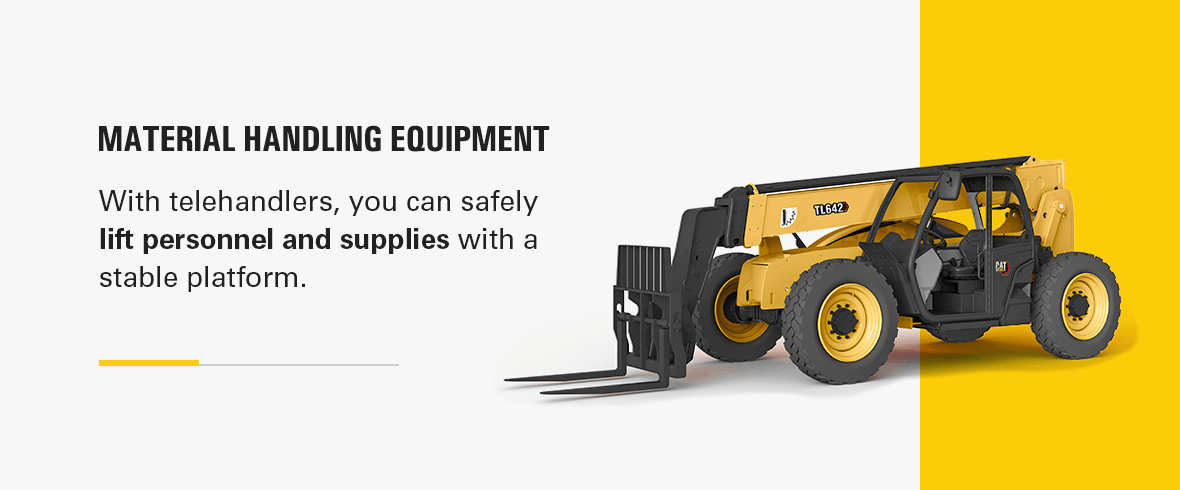

Material Handling Equipment

- Crane trucks: Combine transport with lifting ability.

- Boom lifts: Lift people and materials to tall heights.

- Forklifts: Move heavy loads at ground level.

- Telehandlers: Extend reach for lifting and carrying with stability.

Earthmoving Equipment

- Dozers: Push soil, rock, and debris.

- Excavators: Dig, lift, and load materials.

- Scrapers: Level and clear large sites.

- Compactors: Pack soil for stable foundations.

- Loaders: Can dig like an excavator and haul like a wheel loader.

Rent Industrial Construction Equipment From The Cat® Rental Store

The Cat® Rental Store provides a wide range of industrial construction equipment. From excavators and dozers to trucks and trailers, you’ll find machines for every stage of the project. See our full equipment lineup or connect with your nearest dealer to request a quote today.

FAQs About Industrial Construction

What is industrial construction?

It’s the building of factories, warehouses, and plants for production or distribution.

How is industrial construction different from commercial construction?

Industrial projects focus on safety and efficiency; commercial projects focus on design and customers.

What equipment is used for industrial projects?

Typical machines include dozers, excavators, scrapers, compactors, loaders, trucks, and cranes.

Find The Cat Rental Store Near You