How to Winterize Your Equipment Fleet

If you’re the owner or manager of a company with construction machinery operating in cold climates, you know the challenges that cold weather presents. When the ground starts freezing and the snow starts falling, conditions rapidly change. In no time, you could be weathered in and stopped in your tracks.

Four-season climates in the northern regions like the central mid-west, Canada and Alaska have entirely different operating parameters than in the south or the continent’s coastal areas. Your machinery needs special attention if you expect to perform below zero. It also requires proper preparation for seasonal storage.

Whether you intend to slug it out in the snow or send your equipment to the shed, winterizing it is a must. Storing equipment for the winter or preparing for winter equipment operation takes some forethought and organization. To help you with wintering equipment, here is some valuable information on fleet winterizing.

Jump to a section:

Why Winterize Your Equipment?

If you’re like most people in the equipment operation business, you’ve got a lot of capital tied up in your fleet. Your equipment and machinery are valuable investments. Like all material assets, your equipment requires care and attention. That’s especially true if you’re going to operate machinery in cold weather or store it during the winter.

Temperature is a major factor affecting equipment operation and storage. Just as extreme heat and humidity can damage your machines, an excessive drop in temperature can take its toll. The time and effort you take in winterizing your heavy equipment will have a return on investment that you can’t refuse.

Depending on your business nature and the area you work in, you might have the choice to run your machinery all year long. You might turn your landscaping equipment into an ice and snow removal service. Or, you might choose to park your fleet and wait until the season changes and the great outdoors returns to a comfortable operating temperature.

No matter if you store your equipment for the winter or decide to keep on trucking through the temperature dip, you’ll need to make some modifications to your machines. That might be altering your fuel and lubricant so you can properly perform in the cold. Or, it might mean conditioning your equipment for temporary downtime during harsh weather.

Winterizing your equipment takes time and concentrated effort. It also takes a bit of capital investment. However, routine seasonal-change maintenance and storage preparation have great paybacks that make your efforts worthwhile.

Storing Your Equipment During Winter

If you decide to store your equipment for the winter, there are simple steps you can take to make sure it’s parked in premium condition. Your winterizing tasks ensure that when you return your machinery or attachments to service, they're ready to go. You’ll have no worries that some part, component or assembly has deteriorated over the downtime.

As a machinery owner or operator, you know that machines that sit idle for too long are notorious for having startup problems. Fuel goes stale, oil turn sluggish and rust sets in. These conditions are not good for your machines’ longterm health and performance.

Safely storing equipment for the winter requires a proactive plan. You need to identify vulnerable areas and prevent problems that arise with inoperative and incorrectly stored machines. Here are some proven tips you can use when putting your equipment away for the winter.

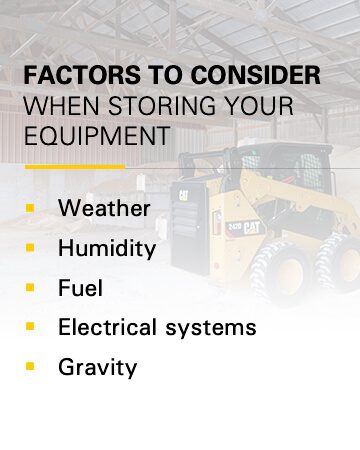

- Weather protection: Direct exposure to weather is the harshest storage for your equipment. Always park your machinery under cover so you can protect it from snow buildup and wind forces. If you have the option, park your assets in a fully enclosed shop or shed or under a tarp.

- Humidity protection: Winter conditions usually bring low air humidity despite the moisture present in ice and snow. Low humidity dries out equipment parts like seals, electrical lines and hydraulics. Indoor storage is the best solution for humidity protection.

- Fuel protection: Parked machines almost always develop fuel problems. That’s unless you take protective steps, especially with diesel-powered equipment. Two options are draining your fuel tank or completely filling it to prevent condensation.

- Electrical protection: Inactive electrical systems are prone to corrosion and cracking. Batteries are also a problem when stored for long periods. You can disconnect and remove your machine’s battery, but often it’s a better practice to leave a trickle charge energizing your electrical system.

- Gravity protection: You might not think of it, but gravity plays havoc on equipment parked through the winter. Tracks can freeze to the ground, and tires develop flat spots. It’s a good idea to set tracked machines on wooden planks and to raise your wheeled machines’ chassis to relieve static tire weight.

Lubricating your equipment before parking it for the winter is a must. If you’re going the cold storage route, make sure you use a grease or oil that has a low viscosity rating so it remains pliable and protective. Lubricants are your first line of defense against rust that invariably tries to set on stored equipment.

Tips for Winter Equipment Use

Parked equipment isn’t profitable equipment. To get the best return on your machinery investment, you’d like to operate it for as long as possible. That might include having it operational during the cold months of November through March.

If you plan to use your equipment through the winter, you need to take some pre-winter conditioning steps. This doesn’t have to be an expensive investment. You just have to do the right things to prepare your machines for their transition from warm to cold.

The best time to winterize your equipment is in the shoulder period when the nighttime temperature begins its frost threat, and the daytime is still pleasant. That’s usually around the end of October unless you’re in the far north. You’ll need to pick your date, and then you can prepare by using these tips for using your equipment during the winter:

- Get information: Don’t overlook your equipment owners’ manual. It likely contains step-by-step winterizing instructions. Another excellent resource is by the US Army Corps of Engineers and is called Winterization and Winter Operation of Automotive and Construction Equipment. It’s somewhat dated, but the winterizing information is timeless.

- Prepare fuel: If your equipment has gasoline power, usually, the only necessary winterizing step is using a de-icing additive. Diesel units in the winter require special attention. You should always use up your #2 summer diesel fuel supply and replace it with a #1 winter diesel blend.

- Change oil: Cold and thick oil makes for hard starting engines. For winter conditions, it makes a real difference to thin out your engine oil to a low-viscosity product like 5W-30 instead of the summertime 10-30 or standard 30-weight. Thinner oil flows faster and reduces drag on internal engine parts that thick weights present. Of all the proactive steps you can take to protect your equipment in cold weather, winterization of oil is one of the most important.

- Check coolant: Pre-winter is the perfect time to check your engine anti-freeze or coolant type. You can have it commercially tested for its temperature tolerance or you can buy an inexpensive tool at most equipment dealers. Make sure you check the level and strength when your engine is cold, and never add water to glycol-based coolants.

- Test batteries: When your battery gets cold, it loses cranking power proportionate to the temperature drop. A winterizing battery check is cheap insurance and so is replacing your summer-rated battery with a cold-weather rated one. A safety tip is never to try charging a frozen battery as it could explode.

- Top off fluids: Your equipment likely has other fluids to winterize besides your engine oil, coolant and fuel. Hydraulic fluid comes to mind. For the best hydraulic performance in cold conditions, it’s worth replacing your fluid with a winter-rated weight. Other fluids to winterize are your windshield washing fluids.

- Examine filters: Pre-winter is the perfect time to examine your equipment’s filters. Clean air filters are critical for reducing internal engine wear and oil contamination. You should also have a look at your fuel filters, oil filters and cabin filters. If in doubt, either clean or replace fouled filters before they become a cold-weather problem.

- Lubricate parts: If there’s one winterizing step that really pays off, it’s thoroughly lubricating your equipment parts. Depending on your machine type, this could be undercarriage components, boom and stick arms or bucket connections. Moving parts on your controls or operator cab also need proper attention with a lubrication oil weight suitable for cold weather.

- Hook up heaters: Auxiliary heaters are handy for cold weather equipment operation. Engine block heaters work well to preheat coolant and oil. Warm engines start quicker and have less frictional wear. You might also want to look at fuel heaters if you’re running diesel engines in the winter.

- Clean machines: It’s tough to keep your machines clean in cold weather. Road salts and grime quickly pile up on busy machines, and contaminants are hard on equipment. It’s worthwhile to give your machinery a pre-winter power wash and periodically follow it up with hot, soapy water.

There are plenty of other useful winter maintenance tips. If your machinery has tires, you want to preset your inflation pressure for cold weather. Tire pressures naturally drop in low temperatures, and untreated air tends to crystalize, which can cause winter troubles. Many equipment owners inflate their winter-use tires with a dry nitrogen additive that won’t freeze or fluctuate in pressure.

It’s also worth having some more fuel discussion when you’re planning on winterizing your equipment. Most construction machinery uses diesel engines. Today’s technology makes diesel engines very reliable and powerful. However, they’re only as good as the fuel they’re fed.

North American equipment runs on two diesel fuel types. One is the #1 blend that’s rated for winter or cold weather operation, and the other is the #2 blend for summer or warm weather running.

You’ll hear two terms with diesel fuel ratings. Those are “cloud point” and “pour point.” Diesel fuel contains a paraffin wax that clouds in the fuel at its gel point and makes the mixture opaque. When paraffin is too cold, it solidifies and stops the fuel’s ability to pour.

Chemists blend diesel fuel to respond to intended temperatures. If you have #2 diesel fuel in your tank when it turns to winter, it will warn you by clouding up before it becomes impossible to pour. The right blend of #1 diesel will keep your machine reliably operating in the coldest times.

You’re probably wondering why machines don’t simply operate on #1 fuel year-round. That’s because there’s a performance trade-off between #1 and #2 diesel. While #1 is less gel-prone in the winter, it doesn’t have the same power generating ability as #2. So for peak performance once the weather warms, make sure you switch your diesel fuel supply to the summer blend.

Here’s a final winterizing tip regarding fuel. Never add gasoline or alcohol to diesel in the hope that it will help #2 fuel winterize. At best, gas or alcohol will damage your diesel’s injection system. At worst, it will cause an explosion.

Fleet Winterizing Checklists

Checklists are helpful aids or tools regardless of what industry you’re in. No airline pilot takes off without following a rigorous checklist routine. To pilots, checklists are essential safety features.

A winterizing checklist can help you get your equipment ready for storage or winter performance. Checklists identify critical control points and remind you to complete each necessary step. Your machinery will be far better prepared and much safer when you’ve followed a proper checklist.

Your winterization checklist doesn’t have to be complicated — the simpler it is, the more likely you'll be to follow it. You can make a master checklist that covers every machine in your fleet. Or, you can make lists that are unique to individual pieces of equipment.

It’s probably best to make two separate lists — one for storing equipment for the winter and one for operating machinery in cold weather. They’re two separate activities, although they share some tasks. Here are examples of checklists for storing winterized equipment and for getting equipment ready for cold-weather operation.

1. Winterizing Checklist for Storing Equipment

Preparing your equipment for winter storage helps ensure your machinery or attachments aren’t negatively affected by inactivity, weather and temperature. It's vital to consider the climate inside your storage facility as well as potential exposure to natural hazards outdoors. These are considerations for storing equipment over the winter.

Storage Facility:

- Know your storage duration and the start and end dates

- Anticipate storage temperature and humidity levels

- Give access to authorized people and prevent unauthorized access

- Protect from wind, rain, snow and ice

- Ensure you have a ground-level surface for equipment support

Equipment Fluids:

- Control fuel by draining the tank or administering winter additives

- Determine whether the coolant is suitable for the lowest anticipated temperature exposure

- Match engine and hydraulic oils for seasonal performance

- Check if your incidental fluids, such as washer, brake or steering fluids, are suitable

- Clean or replace filters for spring startup

Electrical Components:

- Disconnect batteries and store in a warm environment or maintain a trickle charge if leaving batteries in equipment

- Repair all lights and safety devices

- Check and treat all connections with anti-corrosion material

- Change all switches to off position to prevent accidental startup

Chassis, Control Cabin and Work Tool Attachments:

- Lubricate all hinge points with temperature-suitable grease

- Disconnect all drives or put in neutral with brake mechanisms activated

- Place tires and tracks on suitable surfaces to prevent frost attaching or flat spots

- Disconnect all work tool attachments and deactivate power supply

- Fix controls, clean cabin and secure access

Miscellaneous:

- Put rodent and insect control measures in place

- Clean all equipment with rust-resistant products

- Control fire risk and have an emergency plan if necessary

- Get valid insurance for equipment being stored and not operated

- Keep all manuals, guides and directives stored in a separate location

2. Winterizing Checklist for Operating Equipment

Operating your equipment during the winter has its challenges. You need to make sure every component is ready to survive the cold and able to function without failure. Some of the winterizing steps for cold-condition operating are the same as if you are storing your machinery over the winter. Still, it’s handy to have another checklist that addresses winter operation.

Winter Operating Environment:

- Know the anticipated temperature ranges and extremes

- Know the duration of your cold-weather operation

- Identify each piece of equipment's cold-operation specifications or directions

- Anticipate any cold-weather exposure when not in operation

Equipment Fuels and Additives:

- Get your gasoline engine cold-weather additives ready

- Ensure your diesel fuel grade is suitable for the expected temperature (#1 in place of #2)

- Flush your fuel supply to ensure water is separated and contaminates are gone

- Get your fuel pump, injectors and filters winter-ready

- Top off your fuel tank continuously to prevent condensation

Equipment Fluids and Lubrication:

- Ensure your engine oil is compatible with cold-weather operation (5W-30 or thinner)

- Lubricate all movable parts with low-temperature grease

- Ensure your engine coolant can withstand the lowest expected temperature

- Check all additional fluids to make sure they're suitable for the operating range

- Ensure the hydraulic system and oil can function in low temperatures

Suspension, Drives and Undercarriage:

- Clean debris from tracked machines to prevent freeze-up

- Change wheeled machines to winter tires

- Set all tires to winter-operating pressure — nitrogen gas-filled if possible

- Ensure cleats on track machines are suitable for ice and snow traction

- Have chains available for rubber-tired equipment

Electrical Equipment:

- Ensure equipment batteries are capable of cold weather cranking without amperage loss

- Pre-warm battery and engine to ensure they are operational

- Check that all electrical components are corrosion-free

- Test all lights and safety devices

- Test all operator controls

What Happens When You Don’t Winterize Your Equipment?

Failing to plan for winter can cost you. For your expensive fleet of machinery, vehicles and other equipment to survive long-term cold storage or continuously run without winter breakdown, you have to make sure they're ready. You can’t afford not to winterize your equipment properly.

If you store your equipment for the long winter haul without carefully winterizing it, you’re likely to find a tragic mess in the spring. There are horror stories of cracked engine blocks due to frozen coolants and fuel tanks so rusty that they had to be scrapped.

Why risk winter damage when it’s so simple to prepare a winter storage checklist and follow it? A dollar spent on winterizing can be ten saved when you’ve prevented expensive springtime repairs. Don’t let damage happen because you failed to store your equipment for winter’s cold.

The same goes for operating your equipment through the winter. If you fail to winterize, you might end up with non-operational equipment, and you'll have to pass on lucrative jobs. You’ll also run the risk of mid-operation breakdowns in freezing weather that makes repairs nearly impossible.

Failing to winterize your fleet can be disastrous. You might suffer an accident resulting in property damage or personnel injury. At the very least, having an embarrassing stoppage due to improper planning can damage your company's reputation.

It just isn’t worth the potential problems incurred by not winterizing your equipment for storage or cold weather running. Follow the practices of top rental companies by maintaining your equipment for winter storage or keeping it operational throughout the cold season.

Rent Winterized Equipment From The Cat® Rental Store

The Cat® Rental Store is a nation-wide network of construction equipment rental dealers. We operate year-round in some of the coldest climates you’ll find in North American. From Alaska to Nebraska, The Cat Rental Store serves contractors and construction company owners like you with dependable Cat equipment.

At The Cat Rental Store, we believe in keeping our equipment in top shape and prepared for winter operation. We know that storing machinery over the cold months takes a little planning but also that it pays you back in long-lasting and peak-performing machines. Our Cat equipment is winter-ready and prepared for whatever the weather throws at them.

Check out our inventory of construction machinery and tools at The Cat Rental Store. Call us today at 1-800-RENT-CAT or stop by a convenient location near you.

Find The CAT Rental Store Near You