All About Excavators: A Comprehensive Guide

Excavators are the backbone of modern earthmoving. You rely on them to dig, lift, load, and demolish with speed and accuracy.

You’ll find several different types of excavators available, such as mini excavators and extended-reach. Excavators also have complex parts and a surprising array of attachments available.

This guide gives you the big picture and the practical details in one place to help you match the right excavator and attachments to your job.

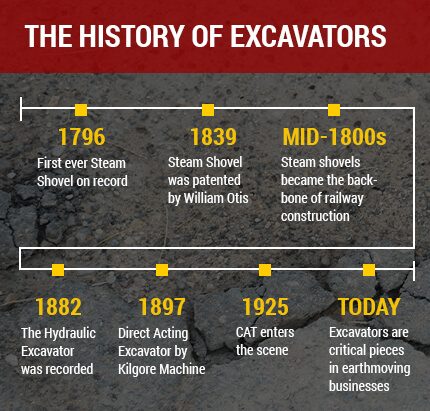

A Short History of Excavators

The story starts with the steam shovel, patented in 1839. It could move 300 yards of material per day. A team of men with picks and shovels could only dig 12 yards per day.

Hydraulics took center stage in the 1890s. The Kilgore Machine Company’s direct acting excavator used four direct-acting cylinders instead of cables, a breakthrough that set the pattern for today’s machines.

In 1925, the Caterpillar Tractor Company popularized steel-linked tracks. Those tracks would serve the company well when it launched its first hydraulic excavator in 1972. Tracks are still the standard for most models. Over the years, excavators have grown in size. Caterpillar offers excavators from 1 to 95 tons.

Innovation continues beyond Earth with NASA’s Regolith Advanced Surface Systems Operations Robot (RASSOR), a concept built for digging on the Moon.

Over two centuries, excavators have evolved into efficient, low-emission, operator-friendly machines with better visibility, tighter swing radius, and smarter hydraulic control.

Main Parts of an Excavator

Every excavator has three core systems that work together:

- Undercarriage: The base of the machine is available with steel or rubber tracks or even wheels, enabling you to work across a variety of terrains.

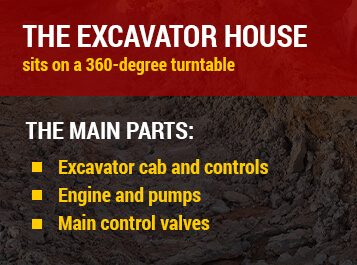

- House: With 360-degree rotation, you can cut and load material quickly and easily.

- Arm: You can dig, lift, and handle all types of material with a variety of attachments.

Options like zero- or reduced-tail-swing, long undercarriages, and upgraded cabs give you better control and safety on tight or complex sites.

Common Excavator Types

You can choose from several types depending on the surface, size constraints, and the work to be done:

- Crawler excavators: Tracked, stable, and ready for rough terrain, crawler excavators balance power and reach for digging, loading, and trenching.

- Wheeled excavators: Wheeled excavators are faster on pavement and easy to move. They limit surface damage and reduce the need for a lowboy between nearby jobs.

- Mini excavators: Compact size and low ground pressure make mini excavators ideal for tight spaces.

- Long-reach excavators: Extended boom and stick make these specialty excavators excellent for digging deep trenches, dredging deep rivers, and doing distant slope work.

- Demolition excavators: These models are engineered for demanding teardowns and can reach work as high as 90 feet.

Explore current excavator types and choose what fits your job and site limits.

Excavator Sizes and How to Choose

There are many excavator sizes, and the right size depends on access, dig depth, and lift needs.

- Mini (up to ~6 tons): Mini excavators fit in tight spaces, are lighter to transport, and produce low ground disturbance. They are good fits for utilities, landscaping, and residential work.

- Small (~6–19 tons): Small-size models offer power and reach while being easy to transport.

- Mid-Size (~20–35 tons): Mid-size models are most common on commercial sites due to their balance of power, reach, and transportability.

- Large (36 + tons): The machines are made for high production digging and loading for large commercial projects as well as mining and quarry work.

Match the machine to the bucket capacity you need, the soil type, and the working range. Oversizing adds cost. An excavator that’s too small can lead to slow cycle times and excessive wear.

What You Can Do With an Excavator

Excavators cover countless situations when you’d use your machine across industries:

- Construction: Dig foundations and basements, trench for utilities, grade slopes and load trucks.

- Roadwork: Remove pavement with breakers, dig ditches, and set box culverts.

- Demolition: Long-reach units bring down structures; smaller machines sort and load debris using grapples and thumbs.

- Forestry and land management: Clear trees and stumps, contour terrain, and install erosion control.

- Quarry and aggregate: Load trucks and maintain stockpiles.

- Waste and recycling: Handle scrap, move bales, and work safely on uneven landfill terrain.

Attachments That Expand Your Excavator

Switching tools takes your machine from a digger to an all-in-one solution. Start by browsing work tool attachments. Common choices include:

- Buckets: General purpose, heavy-duty, grading, and ditch-cleaning buckets match different soils and finish needs.

- Augers: Drill postholes and footings quickly.

- Hammers: Break concrete, asphalt, or rock with high impact energy while keeping operators off handheld tools.

- Grapple: Clamp and lift logs, boulders, or scrap without losing control.

- Thumbs: Hold irregular loads securely with the bucket.

- Rakes: Clear brush, windrow debris, and prepare seedbeds.

- Rippers: Rip frozen ground or hardpan before digging to protect buckets and reduce cycle times.

- Vibratory plate and drum compactors: Compact soil or asphalt right from the excavator, reducing separate machine needs.

- Couplers: Hydraulic couplers swap tools in minutes so you stay productive.

Mix and match attachments to fit your scope. On a site prep job you might rip, dig with a heavy-duty bucket, switch to a grading bucket to finish, then compact the trench with a plate compactor.

Operation Tips That Improve Productivity

Use these practices to work faster and safer:

- Plan the dig sequence to reduce swing distance and repositioning. Work in layers rather than chasing depth in one spot.

- Size the bucket to the material. Wet clay sticks and adds weight. Rock needs abrasion-resistant cutting edges.

- Use the shortest practical stick for more breakout force and better cycle times.

- Keep tracks clean and properly tensioned to prevent premature wear.

- Follow lift charts. Always check capacity at the distance and height where you’ll lift.

Safety Essentials

Safety underpins every excavation. Keep these basics in mind:

- Call before you dig to locate utilities.

- Set up stable work pads. Avoid working over people or open roads.

- Use cab guards and FOPS/ROPS where material could fall or strike.

- Install quick couplers and verify attachment locks before lifting.

- Train operators on slope limits, swing radius, and spotter signals.

Rent or Own? Choosing What’s Right for Your Job

You don’t have to own every machine to run a productive operation. Renting lets you scale up for big pushes, try specialty models, and control costs for seasonal work.

- Match the model to the task. Rent a short-tail machine for urban jobs, a long-reach model for dredging, or a wheeled excavator for street work.

- Avoid downtime. Rentals arrive serviced and ready, often with telematics and safety tech.

- Try before you buy. Validate size, reach, and attachment performance on a real job.

To plan your next project, find a location near you or find the Cat Rental Store near you.

Find The Cat Rental Store Near You

Related Posts

Choosing the Right Size Rental Excavator for Your Project

An excavator is a staple piece of machinery on construction sites because it is so versatile. Learn to find the right size of excavator for your project.

Read More

How to Use a Mini Excavator

Being part of the construction industry means you have access to a wide variety of different heavy equipment, but nothing is as versatile, reliable and easy-to-use as the mini excavator.

Read More

Top Seven Uses for Excavators

With an excavator, you can perform multiple tasks necessary in many heavy industries. Discover the top uses with The Cat Rental Store.

Read More

Wheel vs. Track Excavators

The Cat Rental Store carries a large inventory of excavators in multiple sizes and configurations. Learn which you need - a wheel or track excavator.

Read More