Trench Shoring Equipment Rentals: A Complete Guide

Trench work is one of the riskiest parts of construction. Cave-ins or collapses can cause serious injuries and costly delays. That’s why trench safety is non-negotiable—and why many contractors rely on trench shoring equipment rentals. Renting gives you access to trench shoring solutions without the long-term costs of ownership.

What Is Trench Shoring?

Trench shoring supports trench walls and prevents collapse. By reinforcing the excavation, shoring protects workers inside and maintains the trench’s shape for construction tasks. It is commonly used for:

- Excavated trenches for pipelines or utilities

- Structural repairs or reinforcements

- Gaps or openings between structures

- Sites with unstable soil or nearby demolitions

Proper trench shoring is also required for compliance with OSHA safety standards. For more background, see Cat’s overview of what trench shoring is.

Trench Shoring Methods

There are several approaches to shoring depending on soil conditions and project needs:

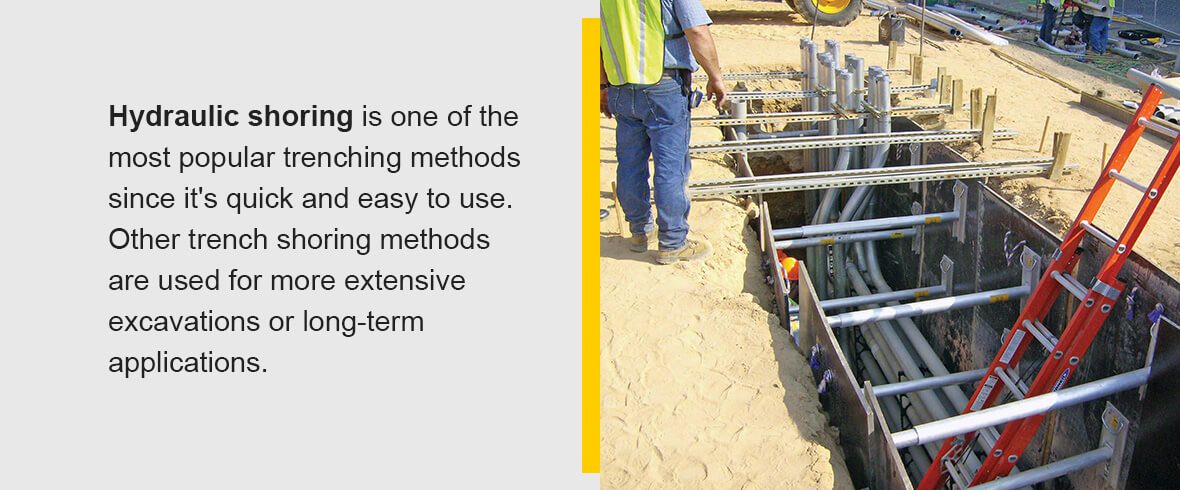

- Hydraulic shoring: Uses aluminum or steel hydraulic pistons to push outward against trench walls. Lightweight, quick to install, and evenly distributes pressure.

- Pneumatic shoring: Similar to hydraulic but uses compressed air. Requires an air compressor but offers a cleaner setup without hydraulic fluid.

- H- and I-beam shoring: Prefabricated beams are driven into the ground with panels slid between them. Effective for medium-depth trenches.

- Sheet pile shoring: Corrugated steel sheets are driven into the ground to create a continuous wall. Ideal for excavations near water.

- Secant pile shoring: Overlapping piles form a continuous concrete wall. Used in tight or obstructed spaces.

- Contiguous pile shoring: Sturdy piles placed in a tight line to retain excavations, best for dry soil conditions.

Each method offers unique benefits based on soil stability, water presence, and excavation depth.

Types of Trench Shoring Equipment

Depending on your method, different equipment can be rented to meet safety requirements:

- Aluminum trench boxes: Lightweight, modular designs that can be quickly assembled and adjusted. Ideal for moderate soil conditions.

- Steel trench boxes: Heavy duty and durable, suitable for deep or complex excavations with unstable soil.

- Steel manhole boxes: Provide solid protection for workers performing manhole installations or repairs.

- Bedding boxes: Hold and dispense bedding materials, improving efficiency and reducing waste.

- Ride-on trenchers: Powerful machines for deep excavation, leaving straight

- Walk-behind trenchers: Smaller, more maneuverable units for shallow or narrow trenches.

Selecting the right equipment depends on trench dimensions, soil type, and the surrounding environment.

How to Choose the Right Shoring Equipment

Key considerations include:

- Soil type: Loose, unstable soil may require steel trench boxes; rigid soils may work better with aluminum trench boxes.

- Dimensions: Deeper and wider trenches need sturdier protection systems.

- Site conditions: High groundwater, nearby structures, or utilities influence method selection.

- Available equipment: Match your site’s excavation machines with the trench box type (e.g., lighter aluminum boxes if only a backhoe is available).

Cat specialists can help evaluate your jobsite and recommend the right rental equipment.

Benefits of Renting vs. Buying Trench Shoring Equipment

For most contractors, renting shoring equipment provides flexibility and cost savings:

- Lower upfront investment: Avoid tying up capital in expensive equipment purchases.

- Reduced maintenance: Rental equipment is inspected and serviced by the provider.

- Storage savings: No need to store large trench boxes when not in use.

- Project flexibility: Rent exactly what you need for each job, from aluminum trench boxes to trenchers.

- Access to technology: Rentals ensure access to the latest safety features and equipment models.

Renting also allows you to scale quickly for larger projects or short-term demands.

Why Rent From The Cat Rental Store?

The Cat Rental Store offers a wide selection of trench shoring rentals, including aluminum and steel trench boxes, manhole boxes, and trenchers. Benefits include:

- Flexible rental terms (daily, weekly, monthly)

- Delivery and pickup for convenience

- Maintenance and repairs are handled by Cat dealers

- 1,300+ global locations for easy access

You can also request a quick quote online to streamline the rental process. Cat’s reputation for safety and reliability ensures you have equipment that meets OSHA and industry standards.

- Avoids long-term commitment: When you buy new equipment, there's much to keep track of, including service contracts, warranties, financing options and interest rates. You must also perform all maintenance and repairs yourself or hire a company to manage these tasks. Renting is a great way to reduce your commitment while gaining access to the equipment necessary to complete your projects.

- Improved flexibility: Renting allows you to respond to specific niches and changing demands. You'll also have access to different types of equipment to meet your project needs, allowing you to perform particular project tasks without committing to brand-new equipment. You can choose from equipment that performs single tasks or machines that can be equipped with attachments so you can complete multiple tasks with one machine. You can also cycle through machines with your rental company based on your needs, changing out equipment as the tasks on your job sites change.

- Access to the latest equipment: Many rental companies cycle out their older equipment to ensure their clients can access the latest technology. Access to some of the newest equipment on the market allows you to perform tasks more efficiently.

Why You Should Rent Trench Shoring Equipment From The Cat® Rental Store

The Cat® Rental Store is a leader in the rental equipment industry. We have a wide range of trench shoring equipment to choose from to help protect your job site and workers from harm. Renting our equipment allows you to try different equipment types before buying. Renting from us is also ideal when working on a temporary project or fulfilling a growing demand without committing to a new purchase. You can rent from us whenever you need, even last minute, helping you complete projects sooner and more efficiently.

We also offer flexible rental terms, whether you need equipment by day, week, month or year. We handle the maintenance and repairs so you don't have to, helping you save more. The Cat Rental Store can deliver your equipment to your job site and offer pick-ups as needed to help you save time and get started on your project as soon as possible.

We aim to satisfy all our customers, doing whatever it takes to ensure you get the most from your equipment and your time working with us. Renting our equipment allows you to protect your workers and keep your project on schedule without worrying about the costs of buying new equipment.

Conclusion

Trench shoring is essential for safety and efficiency in excavation projects. Renting trench shoring equipment gives contractors cost-effective access to aluminum and steel trench boxes, hydraulic systems, and trenchers while avoiding the burden of ownership.

Partner with The Cat Rental Store for reliable trench shoring rentals. Call 1-800-RENT-CAT, request a quick quote, or visit your nearest Cat dealer to equip your jobsite with the protection it needs.

Find The Cat Rental Store Near You