Guide to Types of Forklifts

Making the right choice of forklift can help improve your workplace productivity and safety. This machinery comes in a range of sizes and lifting abilities and varies depending on the situation and worksite. When choosing the right forklift, you need to know your intended use and the type of goods you'll be handling. Our guide to the different types of forklifts will help you choose the best one for your needs.

Jump to a section:

OSHA Forklift Classifications

A forklift is an industrial motorized truck used to lift and transport materials and objects. They're regulated by the Occupational Safety and Health Administration (OSHA) to help ensure operational standards for their safe use in the workplace. OSHA categorizes the different types of forklifts based on how they're powered, how they're operated and where they're used.

According to the Bureau of Labor Statistics (BLS), between 2011 and 2017, there were 614 forklift-related workplace fatalities. It's essential to know how OSHA classifies industrial-powered trucks so safety managers can ensure that everyone who operates a forklift is compliant with OSHA standards.

Below are OSHA's seven forklift classifications:

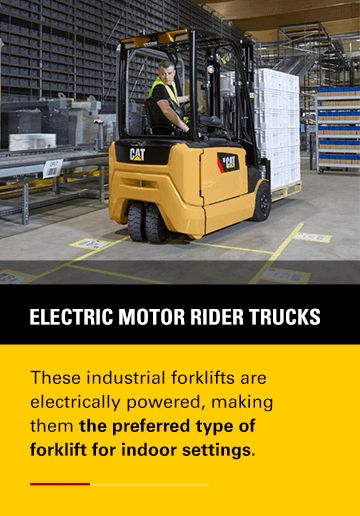

Class I: Electric Motor Rider Trucks

These industrial forklifts are electrically powered, making them the preferred type of forklift for indoor settings. Class I forklifts can be counterbalanced or three-wheeled and have cushion or pneumatic tires. The driver can operate the forklift from either a stand-up or sit-down position, depending on the model.

Class I forklifts are most common in warehouses, retail stockrooms, factories and food storage facilities and are mostly used for stock and pallet moving.

Class II: Electric Motor Narrow Aisle Forklifts

Designed to maximize storage space, electric motor narrow aisle forklifts are used in tight spaces where the aisles are too narrow for a forklift to turn around. These forklifts can be either order-picker or reach truck style — order pickers move inventory perpendicular to the operator, while reach trucks lift loads vertically to the operator.

As extremely maneuverable forklifts, Class II forklifts are designed to quickly and efficiently move inventory in high-traffic warehouses.

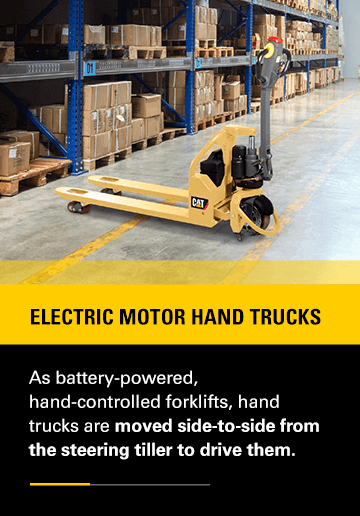

Class III: Electric Motor Hand Trucks

As battery-powered, hand-controlled forklifts, hand trucks are moved side-to-side from the steering tiller to drive them. These trucks can be either walk-behind or ride-on forklifts, depending on the model.

Common types of hand trucks are pallet jacks, walkie stackers and tow tractors. They're typically used for auxiliary support to help manage inventory that bigger forklifts will move later.

Class IV: Internal Combustion Cushion Tire Forklifts

Class IV forklifts are powered by diesel, gasoline or natural gas. Their cushion tires make them ideal for use indoors on smooth, flat surfaces, such as warehouses and storage facilities. This forklift type is most commonly used to transport palletized goods, including loading and unloading delivery trucks.

Since cushion tires are lower to the ground than pneumatic tires, internal combustion cushion tire forklifts can be used in settings with low clearance. There are many different models of Class IV forklifts, with a massive range of weight capacity, from small applications to heavy industrial ones.

Class V: Internal Combustion Pneumatic Tire Forklifts

Class V forklifts are similar to Class IV forklifts but feature pneumatic tires instead of cushion tires. These tires make them ideal for outdoor applications, such as lumber yards and construction sites, but they can also be used indoors.

Like Class IV forklifts, Class V forklifts come in an incredible range of capacities, from single pallet applications to loading cargo containers.

Class VI: Electric and Internal Combustion Engine Tow Tractors

Rather than lift vertically, tow tractors are sit-down or ride-on forklifts that tow loads horizontally. They're commonly used in airports and assembly lines, both indoors and outdoors. They can be powered either by an internal combustion engine, such as a diesel, gas or natural gas engine, or by batteries.

Since tow tractors are typically applied in settings where they need to travel far distances, they're built for speed, high acceleration and tight turning radiuses.

Class VII: Rough Terrain Forklift Trucks

OSHA's final class of industrial forklifts is the rough terrain forklift truck, which refers to any forklift designed for the outdoors and uneven terrain. However, according to OSHA, this definition doesn't imply that all Class VII forklifts can be used on any type of terrain. There are specific settings in which different types of Class VII forklifts are best suited.

For example, a telehandler is a Class VII forklift designed for construction sites. Its low wheel-base and broad weight distribution give it stability, as the telescoping arm can extend several feet in the air ahead of the machine without destabilization.

Types of Forklifts

While OSHA's classifications are essential for safety managers and employers to be aware of due to workplace safety requirements, most people refer to forklifts by their type rather than class. Knowing the different types of forklifts and their uses can help you select the right one for factors like setting, application, weight capacity and more.

While all forklifts are designed to move supplies or materials, either by lifting or towing them, they range dramatically in the way they move and the weight capacity they can carry. Below are 10 different forklift types that are most popular on construction sites or in storage facilities.

1. Warehouse Forklifts

If you're envisioning a forklift, you're probably thinking of a warehouse forklift. These are sit-down forklifts, where the operator controls the truck from the cab, like a golf cart. With hydraulic fork tines extending directly in front of the truck, a warehouse forklift lifts and moves pallets and other large items vertically to place them on or remove them from shelving.

As the name suggests, warehouse forklifts are used indoors in warehouses and storage facilities, particularly to access racking. They're best used for transporting heavy loads, between 1 and 5 tons, over short distances and on flat and even surfaces.

2. Side Loaders

A side loader moves sideways down warehouse aisles. Being sideways, the side loader moves in the same direction as the load, making it useful for transporting goods that are long, such as tubing, piping and lumber. This ability allows them to move down narrow aisles and lift and move the materials without being blocked at the aisle entrances or corners.

These forklifts are most commonly operated from an enclosed cab, but there's also a stand-up model, which is common for indoor spaces. There are also other versions available where the wheels turn 90 degrees to allow for either side or forward transportation.

3. Counterbalance Forklifts

As a type of warehouse forklift, counterbalance forklifts get their name from the weight they have in the back to balance out the weight of the front load to prevent tipping. These forklifts can either be sit-down or stand-up, which allows the operator to quickly enter and exit the forklift between transporting loads.

Another type of counterbalance forklift is the three-wheel version, which allows the operator to easily maneuver in tight circles. This feature makes three-wheel counterbalance forklifts better suited for warehouses with narrow aisles or small spaces in general. They're commonly used in indoor warehouses and can be electric, propane or diesel-fueled.

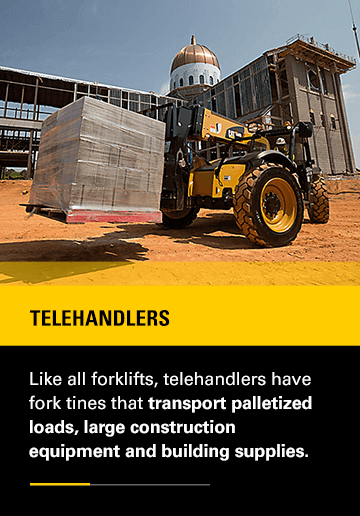

4. Telehandlers

A telehandler is a type of industrial forklift with a boom and a telescoping arm. Acting as a combination of both a crane and a forklift, telehandlers are designed to raise or retrieve loads from very high spaces and often at odd angles. Some models can reach as high as 45 feet, making them ideal on industrial construction sites.

Like all forklifts, telehandlers have fork tines that transport palletized loads, large construction equipment and building supplies. The forks can also be switched out for compatible attachments, making telehandlers highly versatile industrial trucks used across many different industries.

Specifically, large-capacity telehandlers can carry loads of more than 15,000 pounds and are common in the oil, gas and mining industries.

5. Industrial Forklifts

An industrial forklift is a broad term that describes lift trucks with high capacity that are used in heavy-duty industrial applications. These forklifts are standard in warehouses handling substantially heavy items, such as concrete and metal products.

They can also be used to transport brick, quarry and forest products, including loads of more than 30,000 pounds. This ability to carry massive payloads is the key distinguishing feature between industrial and warehouse forklifts.

While industrial forklifts don't have the reach capacity at odd angles like telehandlers, they do have good maneuverability and durability, which are also needed in industrial settings.

6. Rough Terrain Forklifts

Rough terrain forklifts are also called straight mast forklifts and are designed for outdoor use. With large, rugged pneumatic tires, rough terrain forklifts can traverse uneven surfaces, such as rocky, muddy or snow-covered ground.

Built to evenly distribute weight over a larger surface area, rough terrain forklifts ensure the truck and the load remain stable during transportation. Rough terrain forklifts also have weight in the back to counterbalance the front load.

Primarily used on construction sites, rough terrain forklifts transport large and heavy building supplies and equipment. With a powerful engine, rough terrain forklifts can reach high speeds necessary for efficient outdoor work.

7. Pallet Jacks

Pallet jacks are compact powered trucks specialized for lifting and moving smaller loads. Having such a small footprint makes pallet jacks ideal in warehouses storing smaller, lighter loads, such as food and beverage facilities. They're a very popular option because they're affordable and low maintenance.

Pallet jacks are very easy to operate, with the front forks placed directly under the pallet and lifted off the ground by a hydraulic jack. Because they're small, they don't have much reach capacity. Instead, they're generally used to move ground-level loads from one place to another in preparation for shipping or stocking.

8. Walkie Stackers

Walkie stackers are a type of electric forklift without a cab. Instead, they have a platform the operator stands on behind the forks to operate, meaning the operator walks behind the truck. It has an attached handle the operator uses to steer the walkie stacker.

Because they aren't high-powered trucks, walkie stackers are better suited for transporting goods over short distances. Like pallet jacks, walkie stackers are ideal for lighter loads. However, unlike pallet jacks, walkie stackers are used when you need a much higher reach than what a pallet jack can offer.

Walkie stackers are used in warehouses, retail and storage, with some models being designed for narrow aisles.

9. Order Pickers

An order picker is a type of forklift meant to lift workers up to racks or high spots to place or retrieve items. They're electric forklifts used almost exclusively indoors.

Warehouses that stock various goods for customer orders need order picker forklifts to help staff fulfill orders quickly and efficiently. Rather than pulling down an entire pallet or bin to pick products, an order picker allows the worker to go to the storage container to pick out singular items.

10. Reach Forks

A reach fork is a type of electric forklift used indoors, particularly in large warehouses with tall racking. The reach truck's forks extend beyond the truck cab, which is sideways to the load and the forks. This feature makes it useful for navigating narrow aisles in packed warehouses.

The reach truck also has two stabilizer legs, which prevent the truck from tipping when reaching heights with heavy loads. With an open compartment, reach trucks give the operator good visibility for better maneuverability.

Reach trucks are low to the ground, so they're suitable for outdoor use or wherever there are uneven surfaces.

Uses for Forklifts

Just as there are various types of forklifts, there are a variety of ways to use them.

When selecting the right type of forklift for your needs, it's crucial to understand how different types of forklifts are used. Knowing how your business will use a forklift is important to consider before making an investment in a new forklift or choosing one to rent for your upcoming project.

Once you've determined what you need your forklift to do, you can narrow down which type of forklift is right for you. Below are four different ways to use forklifts:

Handling Material and Supplies

The most obvious way to use a forklift is to move materials, whether indoors in warehouses or retail centers or outdoors on construction sites. Moving materials is made much easier with the right type of forklift that's suited for the correct weight capacity.

Some examples of the material handling applications for forklifts include:

- Hauling lumber, steel joists, trusses, drywall and other construction supplies in building supply yards

- Lifting heavy industrial products, like brick, concrete and stone at mines and quarries

- Moving large containers, like dumpsters, recycling bins and portable toilets

On construction sites, specialty forklifts, like high-capacity industrial trucks and telehandlers, are used to transport and hoist these materials during the building process.

Organizing Warehouses

Warehouse forklifts are vital machines in storage facilities for keeping a streamlined operation. Forklifts help keep warehouses organized, well-stocked and easy for workers to navigate. They move and stack pallets, boxes, crates, bins, drums and other containerized goods.

Using a variety of different sized forklifts in a warehouse can help improve efficiency. For example, pallet jacks can be used for small loads to move around the floor, while reach trucks can do the high and heavy lifting of goods, stacking them neatly and safely on racking.

When you need forklifts to help keep your warehouse organized, be sure to select the correct model with the right features for your warehouse layout, including narrow aisle trucks for small spaces.

Loading Shipments

In logistics operations, having a way to quickly, safely and efficiently move shipments to or from delivery trucks is vital to productivity. Having the right kind of forklift for the types of goods you're shipping can help improve your supply chain metrics.

In warehouses, forklifts free up time for other workers to sort and assemble shipments while forklift operators load up the delivery trucks. This ability allows more delivery trucks to be loaded or unloaded at a faster rate.

Other settings, like dockyards, also use high-capacity industrial forklifts to move shipping containers, large palletized loads and more to help expedite shipping operations.

People Moving

Forklifts aren't only for handling goods. They're also an excellent solution for safely moving workers to tall heights. In warehouse settings, order pickers are essential components in the order-filling process because they save tremendous time by bringing the staff to the goods rather than bringing the goods down to the ground for picking.

In industrial capacities, telehandlers can be outfitted with baskets or platforms to raise workers to heights safely. That's beneficial when making repairs, installing equipment or in general construction.

When using forklifts to move people, the proper safety requirements must be implemented, such as OSHA-compliant guardrails to prevent falls.

Factors to Consider When Choosing Forklift Types

When choosing the right type of forklift, you must consider what it'll be used for and where and how much weight it should hold. With such a wide variety of forklifts designed for specific uses, it's important to be aware of the different factors that determine the right way to use any given forklift type.

When deciding which type of forklift to choose, consider the following factors to choose the right one:

Location

The first thing to think about is where you'll be using your forklift — indoors, outdoors or a combination of both. Generally, electric forklifts powered by industrial batteries are preferred for indoor settings because they don't exhaust fumes. Indoor surfaces are also much smoother and more even than outdoor surfaces.

Internal combustion engine forklifts are better for outdoor use because they're typically more powerful, allowing them to navigate outdoor terrain. Additionally, outdoor use forklifts need to be able to navigate rougher terrain.

Capacity

The next consideration in your forklift needs is the lift capacity. There's a huge range of forklift capacities available — from pallet jacks for small, light loads of a few hundred pounds to high-capacity forklifts that can lift tens of thousands of pounds of weight.

If you handle various weights, finding a forklift with a higher maximum capacity is a good choice to err on the side of caution. However, you want to avoid choosing a forklift that's overkill for the job because they're more expensive, have greater power requirements and are more challenging to operate.

Lift Height

Height requirement is another crucial consideration. When determining the right forklift for the job, calculate the maximum reach you need to safely hoist or retrieve materials. Consider both the average height and the maximum height to determine the range of forklift reach capacity you need.

In addition to your reach height, you'll also need to consider clearance restrictions. If there are low-hanging light fixtures or overhead beams or installations, choose a forklift that can be safely operated indoors without obstruction.

Tire Types

Different classes of forklifts have different tire types. Deciding between pneumatic against cushion tires is the common choice you'll need to make. Cushion tires are made of solid rubber and are ideal for indoor uses, such as in warehouses and storage facilities. Cushion tires glide smoothly over even, solid surfaces.

Pneumatic tires are air-filled and can handle larger-capacity loads. They're typically used in outdoor settings, such as lumber yards, dockyards and graded construction sites. Rough terrain forklifts have heavy-duty pneumatic tires meant for rugged and uneven ground.

Rent vs. Buy

Your final decision in choosing the right type of forklift for your needs is whether you'll rent or buy. Renting a forklift is a good way to try out the right model before you make an investment. Forklift rentals are also convenient for one-off needs, shorter contracts or seasonal projects.

With low overhead expenses and no need for ongoing maintenance responsibilities, renting a forklift from a reputable dealer is a cost-effective option.

Which Industries Use Forklift Rentals?

No matter your industry, The Cat® Rental Store has you covered when you need a forklift rental. Our selection of forklifts has options suited to the following applications and more:

- Agriculture and animal husbandry

- Construction and landscaping

- Educational facilities improvement and upkeep

- Material transportation

- Warehouses and facilities

- Waste management

Popular OEM Brands From The Cat® Rental Store

The Cat Rental Store is proud to offer products from trusted OEM brands like the following to provide material handling solutions:

- Liftking: For more than half a century, Liftking has refined the rough terrain forklift and created models with exceptional value and stringent specifications. Liftking is renowned for the flexibility, reliability and convenient technology built into its equipment. The company's heavy-duty forklifts are built to meet the greatest challenges of the military and commercial industry, as well as exceed performance in the lumber, agriculture and mining industries. Liftking forklifts come in lift capacities between 5,000 and 65,000 pounds.

- Master Craft: Master Craft forklifts are built to meet the demands of agriculture, manufacturing and construction projects. They're versatile enough to do everything from demolition and load-hauling to earthmoving and material handling. Our Master Craft selection includes the MC/M Series forklift, the MC Fox forklift, the MC Tugger III and truck-mounted backhoes.

Rent a Forklift From The Cat® Rental Store

With so many different types of forklifts and factors to consider, it's vital to get expert help in making the correct decision. For rental equipment expertise you can rely on, partner with The Cat® Rental Store. Forklifts for rent at The Cat Rental Store are high-quality and well-maintained industrial trucks available at competitive prices.

With over 1,300 global locations, you'll find the forklift you need at a store near you. Browse our inventory of forklifts and material handlers for rent to find the one you need. For more information about forklift rentals, contact The Cat Rental Store at 1-800-RENT-CAT.

Find The Cat Rental Store Near You