Trenchers vs. Excavators: Which Should You Rent?

You have several options if you're looking to rent equipment for digging, earthmoving or material-handling requirements. Two standard pieces of equipment for completing these tasks are trenchers and excavators.

How do you know which is best for your project? Explore the differences between trenchers and excavators, along with tips for deciding which machine to rent for the job.

Jump to a section:

What Is an Excavator?

According to OSHA, an excavation is any cut, depression or cavity formed by removing terrain. It can be any shape, size or depth. Leveling a driveway, laying a foundation and digging out a swimming pool are all examples of excavation.

An excavator is a heavy piece of construction equipment containing a bucket, arm, cab and boom. It is situated on an undercarriage with wheels or tracks. Excavators are primarily used for digging, lifting and carrying different materials, such as soil and gravel. They can cut into and remove earth to prepare surfaces for a variety of construction and landscaping tasks.

Types of Excavators

What are the different excavators you can rent? Let's look at a few types of excavators and how they operate.

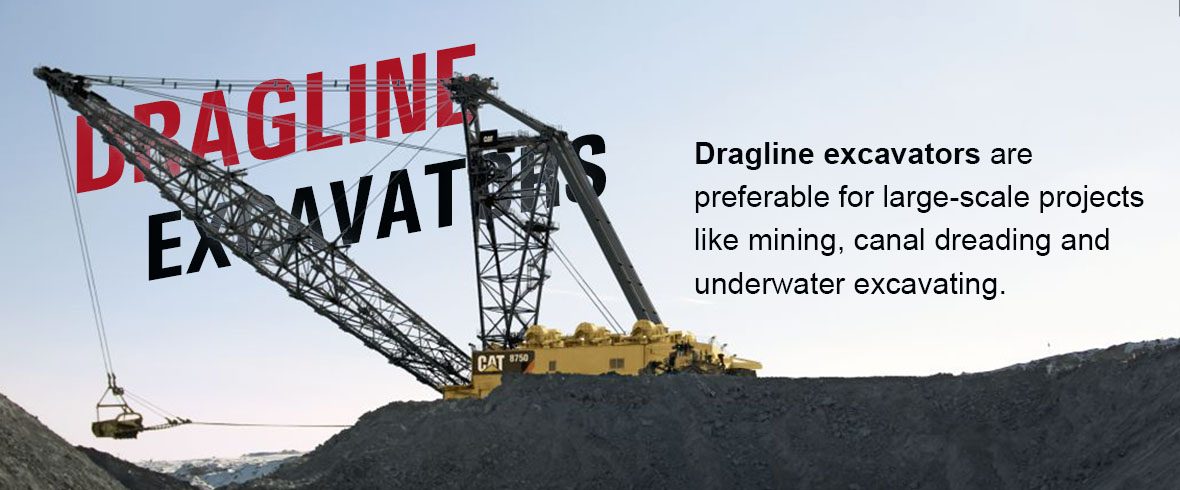

1. Dragline Excavators

A dragline excavator uses a hoist rope network that attaches to a bucket. The other side of the bucket connects to a dragline that runs to the cab. The dragline pulls the bucket toward the operator as the rope raises and lowers the bucket.

Dragline excavators are preferable for large-scale projects like mining, canal dreading and underwater excavating. Their significant size and weight make them unreasonable for smaller jobs and spaces.

2. Skid Steer Excavators

Skid steer excavators have booms and buckets facing away from the operator. This setup allows the attachments to reach over the cab instead of around it. As a result, the excavator can handle challenging turns and narrow spaces more effectively.

Skid steer excavators are great for applications with far-apart objects and minimal space. They're often used for tasks like site cleaning, pool digging and debris removal. However, they're less reliable on slippery and uneven surfaces.

3. Wheeled Excavators

As the name suggests, wheeled excavators operate on wheels rather than tracks. This configuration helps them maneuver asphalt, concrete and other flat surfaces more efficiently — all while providing the same power capabilities. Therefore, they're the typical excavator of choice for roadwork projects.

Their higher center of gravity gives them less stability than tracked undercarriages. They're less viable for projects involving uneven terrain.

4. Crawler Excavators

Unlike wheeled excavators, crawler excavators operate on two large tracks. They're well-suited to heavy-duty construction and mining applications. They can seamlessly grade hills and landscape irregular terrain.

These units use hydraulic power mechanisms to lift heavy soil and debris. Though slower than other excavators, crawlers offer impressive stability and balance on uneven terrain. Their chain-and-wheel orientation lets them safely scale and slide down hills. They also exert less ground pressure than wheeled machines.

5. Long-Reach Excavators

Long-reach excavators feature an extendable boom and arm, letting operators maneuver hard-to-reach locations with ease. Many can reach over 100 feet horizontally. They can tackle challenging demolition projects, such as breaking down walls over bodies of water.

You can also connect different attachments to the arm to perform other tasks like crushing, cutting and shearing. As you can likely imagine, these massive machines are less practical for small, tight spaces.

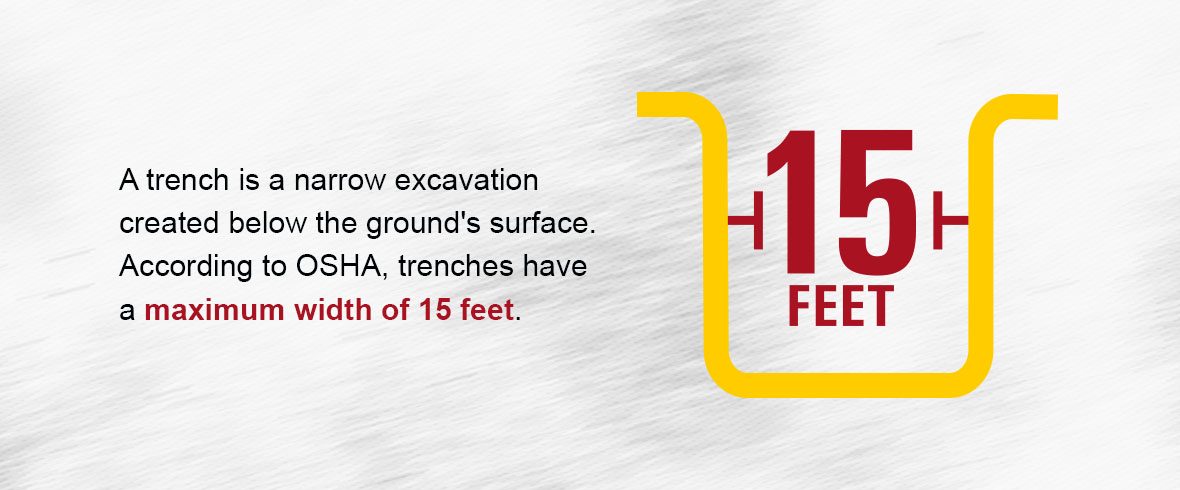

What Is a Trencher?

A trencher is a type of heavy earthmoving equipment that digs exactly what the name suggests — a trench with smooth walls and a flat base. A trench is a narrow excavation created below the ground's surface. According to OSHA, trenches have a maximum width of 15 feet. Typically, their depth exceeds their width.

Trenchers are mainly used to create trenches for:

- Installing, repairing and maintaining pipes.

- Laying electrical cables or wires.

- Placing drainage, plumbing and sewage lines.

A trencher size can range anywhere from a large ride-on model to an attachment for a tractor or skid steer loader. It has a metal chain with high-strength steel teeth. These components allow the trencher to dig into the ground to lift and move large material quantities. Trenchers can tear through densely packed earth and heavy tree roots due to their immense size and strength.

Types of Trenchers

Here are some different types of trenchers and how they work.

1. Walk-Behind Trenchers

Walk-behind trenchers are generally affordable, economical and eco-friendly, creating less environmental disruption. They require manual operation with a set of handles for steering. While they warrant more physical labor, they can easily maneuver compact spaces. They also cause minimal damage to the terrain.

Since this type of trencher offers less horsepower, it's sensible if you're only digging a narrow trench a couple of feet deep. It's too lightweight for high-power applications.

2. Ride-On Trenchers

Ride-on trenchers are usually larger than their walk-behind counterparts. They can produce deeper, wider and longer trenches at higher speeds. They work well for projects requiring greater digging depths, ample power and tougher terrain like rocky soil or pavement. Unlike walk-behind models that only churn out around 13-25 horsepower, many ride-on trenchers generate around 50 horsepower.

If you need to rent equipment for bigger jobs and don't have space restrictions, a ride-on trencher may be your best option. Though ride-on trenchers can efficiently handle rough terrain — all while requiring less physical labor from the operator — their sheer size makes them unsuitable for smaller jobsites and tight spaces. They also tend to cut less precisely.

Trencher Cutting Methods

Both walk-behind and ride-on trenchers are available in two cutting types:

- Wheel: A wheel trencher contains a disc where different cutting parts — such as saws, spades and scoops — can be installed. These cutting components come in various materials and shapes, depending on the job's requirements and terrain. Wheel trenchers can extract both hard and soft soil. Many can break pavement, concrete and stone faster and more accurately than hydraulic hammers.

- Chain: A chain trencher contains a bar or arm with a toothed chain resembling a chainsaw. It has a belt or chain that digs deep, narrow trenches and cuts through hard ground. The cutting elements that can be installed on the chain — as well as the blade's length and thickness — can vary depending on the application. A chain trencher can maneuver varying depths, angles and terrains. Chain trenchers also provide more control over the depth of the cut than wheel trenchers.

What Is the Difference Between a Trencher and an Excavator?

While trenchers and excavators serve similar purposes, a few factors set them apart.

1. Cut Quality

The type of ditch and the quality of work are probably the most obvious differentiators between excavators and trenchers. The excavator's bucket teeth produce a jagged pit with an uneven base and walls. Because the excavator creates a ditch with a top that's considerably wider than the bottom, you're left with substantial backfill.

Meanwhile, a trencher can dig smooth, straight trenches. The machine has vertical walls and flat bottoms, resulting in cleaner, more precise trenching. Most trenchers yield neater cuts than excavators, even in particularly rocky terrains. The teeth on the trencher's arm can quickly pick up small rock fragments while keeping everything clean.

2. Efficiency

Trenchers tend to get the job done more efficiently than excavators. A trencher can quickly produce a trench and deposit the backfill on each side. The crew can then follow behind with a dozer, pushing the backfill into the trench. Most trenchers can take on heavy rocks and dense soil with ease.

An excavator creates large chunks of material that can't be reused immediately. Workers typically have to haul in usable backfill, extending the time and cost of the job. Unlike trenchers, excavator buckets struggle with rocky terrains. That means the rock must be hauled away, pulverized by a rock crusher and then transported back to the site to serve as backfill.

Time is of the essence when it comes to construction and landscaping projects. In many cases, a trenching machine can complete tasks several times faster than an excavator.

3. Versatility

While excavators aren't as quick as their trenching counterparts, they're more versatile. Excavators can accommodate numerous types of terrain and create sloped trenches. Their wheels allow them to maneuver rough, uneven concrete, asphalt and multiple soil types.

They can also dig much deeper than excavators. To put it in perspective, trenchers usually dig anywhere from 1 to 18 feet deep, depending on the size of the machine. Most excavators can reach depths of over 40 feet. An excavator is the clear winner if you need to dig a wider, deeper trench.

What's more, excavators are excellent multi-taskers. For instance, you can dig a trench and then switch out attachments for another application.

On the flip side, trenchers are more limited in their settings. Compared to excavators, they tend to perform less efficiently in varying depths, widths and soil conditions. This makes them impractical for complex digging projects and those that require switching between different tasks.

Key Considerations When Renting a Trencher or Excavator

Before deciding to rent a trencher or excavator for your project, it's important to think about your jobsite, digging specifications, budget and other factors. Here are a few considerations when selecting the right earthmoving equipment.

1. Worksite Conditions

Think about the area you'll be working in, especially in terms of space limitations and terrain. These variables can help you determine your equipment's size and power requirements. If you're working with soft soil, a finished sidewalk or parking lot, or another sensitive surface, you might gravitate toward a lighter excavator that won't wreak havoc on the terrain.

Additionally, consider a smaller model if your worksite has restricted space due to obstructions, such as trees and neighboring buildings. An excavator with minimal or no tail swing can effectively navigate around these obstacles. Opt for a smaller bucket with high precision if you need to work around underground utility lines and pipes.

If you're working in a spacious area with little to no hindrances — and you need more power for larger-scale jobs — choose a bigger excavator or trencher model to handle these tasks more efficiently.

2. Soil Composition

Soil conditions will influence the amount of power necessary for the job. Excavators can reach further into the earth than trenchers, making them suitable for digging deeper holes into dense dirt. If the soil has rocks, pavement or ice over it, the machine may need a pick or hammer attachment to penetrate the material.

Furthermore, the bucket should support the weight of the soil. Soil with heavy rocks or clay will require heavy-duty buckets, while lightweight buckets should suffice for dry soil or light sand.

3. Digging Depth and Width

The type and size of the hole you're digging will play a fundamental role in your decision. Choose a trencher if you're digging a narrow trench no wider than 15 inches. For example, you can use this machine to create a small opening in the ground for laying pipes.

Meanwhile, an excavator is more pragmatic for larger width and depth specifications. Additionally, the wider the hole you're digging, the more horsepower you'll need. The size of the excavator's bucket will determine the space's width.

This means that when making a wider and deeper ditch, the unit must be large and powerful enough to handle a larger bucket. While you could use an excavator with a smaller bucket several times, it would be far more time-consuming than necessary.

4. Budget

Budget tends to be a main concern when purchasing equipment, as you have ongoing maintenance and storage costs to account for. However, it should still factor into your decision when renting a trencher or excavator.

In most cases, the bigger the equipment, the higher the rental fee. You won't receive the optimal return on investment if a machine is overkill for your project. Try to choose the smallest machine possible that successfully fulfills the task.

For example, let's say you need to dig soil for a deep ditch in a compact area where a standard-sized excavator wouldn't fit. In that case, it makes sense to rent a mini excavator. Similarly, you'd be better off renting a small walk-behind trencher if you only need to dig a 3- to 4-foot trench.

5. Project

Digging depth and width are vital considerations when choosing rental equipment. However, if the project entails multiple tasks, digging is only one aspect of the decision. On top of digging, you may also need to move soil, rocks and other materials around the worksite. As discussed earlier, excavators are incredibly flexible for multi-purpose applications.

If your project warrants multiple tasks without requiring the additional power of a backhoe, consider renting a compact skid steer excavator. This solution is feasible for smaller jobsites where digging and grading the area is required to form the desired terrain. Meanwhile, backhoe excavators are better for large projects that call for multiple equipment attachments.

Whatever your digging or earthmoving needs, the many attachments available for different excavators make them a staple for versatile projects.

Best Uses for Trenchers

To help you determine if you should rent a trencher or excavator for your project, we'll look at some popular uses for each machine. We recommend renting a trencher for the following applications:

- Cutting rocky surfaces: Wheel trenchers are great for cutting through stubborn terrain like pavement, concrete and rock. They're ideal when you need to create straight, clean trenches. They can also handle patch and joint replacement projects on streets and highways.

- Snipping and severing tree roots: A trencher's blade can act as a rotary lawn mower blade to slice through plant and tree roots.

- Drainage projects: Instead of digging several feet of soil, you can use a trencher to create trenches for water or sewage runoff. A portable trencher lets you dig up the soil so irrigation piping can run underground.

- Shoveling: A small walk-behind trencher is useful for quick digging projects requiring depths of 3-4 feet.

- Utility applications: Trenchers can dig up earth so you can run pipes, wires or cables underground. They can also dig up the ground when you need to reach these components for removal, maintenance or repair.

Best Uses for Excavators

Additionally, here are some standard uses for excavators:

- Material handling: Reinforcing your excavator with a clamp attachment lets you take on various material handling requirements. You can lift and transport materials that a standard bucket attachment wouldn't be able to hold, such as large pipes, rocks and boulders.

- Earthmoving and debris removal: Digging and earthmoving are perhaps the most common excavator use. Whether digging holes or trenches, grading land or completing general landscaping tasks, its bucket and teeth can seamlessly dig and scoop materials like dirt, rock and soil. You might dig a trench to set a foundation, install piping or wires or create a seed-planting area. An excavator with a grab attachment can clear materials from the jobsite, making it a go-to for debris removal.

- Demolition: You can equip your excavator with a breaker attachment to perform different demolition tasks, like breaking concrete or stone.

- Underground and underwater excavation: Excavators can dig underground passages — also known as tunneling. Equipping the machine with bucket and auger attachments can yield peak results. Furthermore, some excavators can work in water, especially when braced with extended attachment arms and roller chains.

- Forestry: An excavator can streamline forestry projects by moving, cutting and shearing branches to create access routes. There are numerous attachments — like mulchers and shears — for handling trees and other forestry materials.

Should You Rent a Trencher or Excavator?

We recommend renting a trencher if:

- You need to make straight, clean and precise cuts.

- You're digging a smaller trench or need to complete small projects quickly.

- Your project doesn't require alternating between multiple tasks.

We advise renting an excavator if:

- You're digging a wider and deeper trench.

- You're switching between different tasks throughout the course of the project.

- You're working on a larger, more time-consuming project.

Find the Equipment You're Looking for at The Cat® Rental Store

Whether you're looking to rent a trencher or excavator, you can find quality machinery at The Cat® Rental Store. You can enjoy the following benefits when you choose us for your rental equipment needs:

- Access to a wide inventory of meticulously inspected and maintained equipment

- Cost-effective options and flexible rental terms

- The ability to try before you buy

Our rental equipment includes the latest technology and features for more productive projects. Additionally, our reliable dealer network ensures you receive expert guidance and support at every step of the rental process. Browse our selection of rental trenchers and rental excavators and request a quick quote today.