30 Construction Equipment Names Everyone Should Know

There are dozens of types of construction equipment available, ranging from common machines you'll see on nearly any job site to obscure devices used for specialized tasks. Even experienced workers in the construction industry may encounter equipment names they are unfamiliar with from time to time. If you're just starting out in the industry, there are likely many equipment names you have yet to learn.

We've compiled a list of 30 key pieces of construction equipment so you can learn about each of them — what they look like, how they work and what they accomplish. These equipment types come from various construction sectors, including roadbuilding, demolition, building, forestry and more.

Jump to a section:

1. Backhoe Loader

A backhoe is an extremely common piece of excavating equipment. The term "backhoe" technically refers to the attachment — an arm with a digging bucket at the end — which can mount to various types of heavy machinery. Oftentimes, "backhoe" is shorthand for a backhoe loader: a backhoe attached to a front loader. This machine is considered the most versatile earthmover in the construction industry. It includes a bucket in the front and the backhoe attachment in the back, which allows you to excavate trenches, load and unload materials and lift objects.

2. Boom Lift

A boom lift is a mobile machine, typically with wheels. It includes a long crane with a platform or bucket at the end that is typically large enough for one or two workers to stand on. This aerial lift allows workers to access elevated areas safely on a construction site, such as an upper story on a building's facade. Boom lifts come in both articulating and telescopic options.

3. Bulldozer

A bulldozer, also called a dozer, is a staple piece of construction equipment. It consists of a tractor, typically on tracks rather than wheels, with a large metal bucket plate. Operators use the plate for tasks like digging, excavating and leveling soil and other materials. You can also use a bulldozer for demolition, to break up compacted materials and to clear snow. Dozers are available in a wide range of sizes for different tasks.

4. Cold Planer

A cold planer is a milling machine for asphalt and concrete. As the machine grinds the asphalt on a road or other surface, it moves the ground asphalt up from the drum using a conveyor belt system. The operator follows closely behind a dump truck so the loose asphalt lands in the back of the truck. Cold planers are used primarily when it's time to resurface a road.

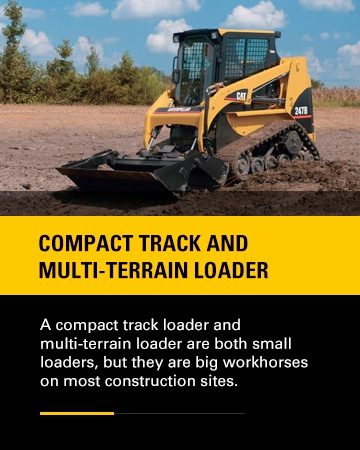

5. Compact Track and Multi-Terrain Loader

A compact track loader and multi-terrain loader are both small loaders, but they are big workhorses on most construction sites. These small loaders provide a convenient way to move materials around a job site. You can also add attachments to accomplish all sorts of tasks. The difference between these two machines is that a compact track loader has an undercarriage designed for more rugged environments, while a multi-terrain loader has lower ground pressure and is a safer choice for more delicate surfaces.

6. Compactor

A compactor is a machine that compresses and reshapes a surface like soil, gravel or asphalt. This makes them a valuable asset to road building and other construction tasks. Compactors come in many shapes and sizes. One common type is a plate compactor, which is a device you push similarly to a lawnmower. The base plate vibrates and evens out the surface underneath. Another common type is a road roller, a vehicle with a large rotating cylinder that compresses the surface beneath.

7. Dragline Excavator

A dragline excavator is a large piece of equipment used for deep excavation projects. This machine includes a long boom with a digging bucket suspended at the end. Operators control the bucket with a system of ropes and chains. Some dragline excavators are small enough to be transported to a job site, while larger dragline excavators — often used for strip-mining operations — are assembled on-site. Some of these dragline machines can weigh thousands of tons.

8. Drill Rig

You may not see a drill rig at every construction site, but they are a staple at any type of well. Whether you're trying to access underground water, oil or natural gas, a drill rig can help. Some drilling rigs are extremely large. The tall structure you see is called a derrick, but there are many other components that work together to drill into a material. On the other end of the size spectrum are augers, small drilling rigs a single worker can operate manually.

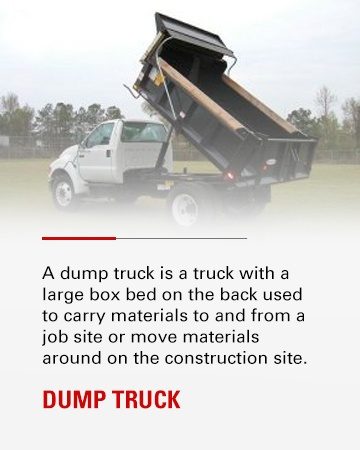

9. Dump Truck

A dump truck is a truck with a large box bed on the back used to carry materials to and from a job site or move materials around on the construction site. The operator can lift the front end of the truck bed with the help of hydraulic rams in order to dump the materials inside. This makes it easy to deposit materials at a dump site or job site. Some dump trucks are designed to be driven on the road, while others are off-road vehicles designed to navigate rugged terrain.

10. Excavator

An excavator is another staple piece of construction equipment used for a variety of tasks. An operator sits inside a cab that rotates 360 degrees. This is why you'll sometimes hear an excavator referred to as a 360. The cab sits atop an undercarriage, typically with tracks, though some excavators are equipped with wheels. Operators use the bucket attached to the end of a stick and boom that extends from the cab to dig, lift and perform other actions.

11. Feller Buncher

A feller buncher is a valuable asset in logging and land clearing operations. A feller buncher consists of a cab on tracks or wheels with an attached boom. So far, this may sound like an excavator or other similar pieces of equipment. The main thing that makes a feller buncher unique is the feller buncher head at the end of the boom. This device wraps around tree trunks and cuts the tree at the base using a chainsaw before depositing the tree somewhere to be carried off.

12. Forklift

Forklifts are especially common in warehouses, but you may also see them on a construction site since they help with all sorts of material handling. A forklift looks like a small car with a mast, lift cylinder, backrest and carriage at the front, along with forks that extend forward from the bottom of the cab. These components allow you to lift materials, like pallets of bricks, or move them from side to side. There are various types and sizes of forklifts designed for different applications.

13. Forwarder

Like a feller buncher, a forwarder is a helpful piece of forestry equipment. Whereas a feller buncher cuts down trees and deposits them into a pile, a forwarder carries logs to a loading site. This piece of equipment is essentially an off-road truck, typically with eight wheels and a mechanism for carrying logs — holding them just above the ground so they don't drag. This distinguishes a forwarder from a skidder, which drags trees on the ground. A forwarder is limited in the size of logs it can carry.

14. Front-End Wheel Loader

Wheel loaders are one of the most multi-purpose types of construction equipment available. As the name suggests, these loaders use wheels to get around a job site. The default attachment is a bucket that can scoop up, move and unload materials. You can also use other attachments, such as augers, backhoes and rippers to help with a variety of tasks. Wheel loaders come in a range of sizes from compact to large, so you can choose the model and attachments that are best suited to your work.

15. Grader

Also called a motor grader, a grader is an important piece of equipment for roadbuilding. It includes three axles — two at the back and one in front — with a metal plate running between the axles. It usually has six wheels to accommodate the long frame. The metal plate grades the dirt or gravel beneath as the operator drives the machine over an area. The cab where the operator sits is just above the back axles. Graders are essential for creating a flat, even surface before building a road.

16. Harvester

A harvester is a piece of forestry equipment used to harvest logs. This machine has a heavy cab and an attached arm that operators use to clear-cut areas and grab logs. A special attachment at the end of the arm helps to cut, process and debark trees. Harvester attachments are made to adapt to different sizes of trees for maximum versatility. This equipment comes in wheeled and tracked varieties to accommodate the work site where it's used.

17. Knuckleboom Loader

A knuckleboom loader is another device used for logging. Once a forwarder or skidder has deposited logs at a loading site, a knuckleboom loader takes over to load the cut and stripped logs onto a truck so they can go to their final destination. A knuckleboom loader is a swing machine with a crane head that is specially designed to pick up logs and efficiently load them onto a truck. The cab of a knuckleboom loader can be mounted on a trailer or it can run on wheels or tracks.

18. Manlift

The term "manlift" can be used to label the whole category of aerial lifts, which includes boom lifts, scissor lifts and more. However, according to the Occupational Safety and Health Administration (OSHA), a manlift refers to a device with a power-driven belt that only moves in one direction and is intended to transport workers from floor to floor. These are also called vertical personnel lifts since they move up and down, not side to side. They are typically designed to transport one worker at a time.

19. Mixer

In construction, a mixer is a truck equipped with a large drum that mixes concrete. All the operator has to do is add dry cement, aggregate and water and let the drum rotate to mix the materials and form wet concrete. The drum has a spiral blade on the inside to assist with mixing. Some trucks are dedicated concrete mixers, but you can also find mixer attachments or stationary mixers to use on a job site when you need to pour concrete.

20. Mobile Crane

A mobile crane is an extremely useful piece of equipment for lifting and moving objects. As the "mobile" part of the name suggests, these cranes are equipped with wheels or tracks so you can drive them around a job site, especially if they're an all-terrain model. Most cranes use hydraulics to move the hoist mechanism, which has a hook at the end to hold objects. Some mobile cranes are able to rotate 360 degrees, making it even easier to navigate tight spaces.

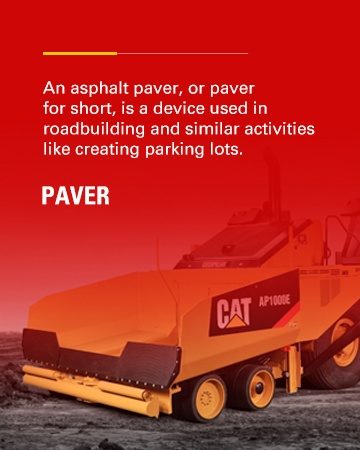

21. Paver

An asphalt paver, or paver for short, is a device used in roadbuilding and similar activities like creating parking lots. Typically, a dump truck continuously feeds asphalt into the paver's hopper, located at the front of the machine. This allows the paver to spread the asphalt evenly on the intended surface. The paver also compacts the asphalt with a small roller, but a road roller is still necessary for packing it down and smoothing it out even more.

22. Pile Driver

For deep foundation work, a pile driver is an essential piece of equipment. In a typical pile driving system, a boom extends from a crane. Attached to the boom is a lead, a frame used to align the pile, along with a hammer and pile. Pile driving equipment lifts a pile and then drives it into the soil until it reaches the appropriate depth. This provides vital support for deep foundations.

23. Scissor Lift

A scissor lift is a type of aerial scaffold. Scissor lifts use a system of crisscrossed metal jacks to raise and lower the platform. Like a manlift, they do not move horizontally. These lifts are powered by either electricity or an engine. Scissor lifts are most popular in warehouse settings since they allow workers to reach high storage areas. They can also help construction workers access high points or upper levels of a building.

24. Skid Steer Loader

A skid steer loader is a versatile, compact piece of construction equipment on four wheels. It gets its name from the fact that skid steer operators must use differential steering — a method in which you propel one side of the vehicle forward while leaving the other locked, causing the equipment to skid in the intended direction. This method of steering gives skid steers an impressive turn radius, making them perfect for operating in tight spaces. You can attach all sorts of work tools to a skid steer.

25. Skidder

A skidder performs a similar function to a forwarder. The main difference is that skidders tend to drag trees along the ground and can typically handle a more diverse range of tree sizes compared to a forwarder. The traditional skidder is a cable skidder which uses a cable to pull trees. Like a forwarder, a skidder deposits trees at a loading site where they can be cut down further and loaded onto a truck.

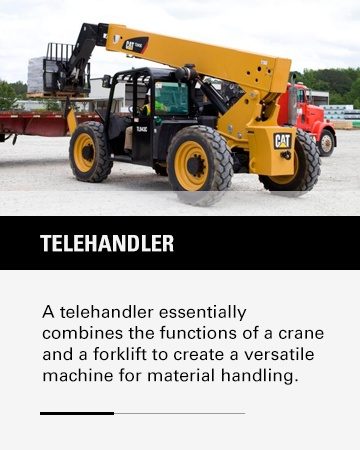

26. Telehandler

The name telehandler is short for telescopic handler. Telescopic refers to the telescoping boom on this machine, where you can attach various tools for different tasks. Aside from the boom, this machine looks like a bigger, more heavy-duty forklift. A telehandler essentially combines the functions of a crane and a forklift to create a versatile machine for material handling. Compared to a forklift, a telehandler has larger tires that are better suited for off-road applications. It can also reach higher and perform more tasks.

27. Tower Crane

Tower cranes are larger than the mobile cranes mentioned earlier. In fact, these massive cranes are not at all mobile. They are fixed in a specific location, typically mounted in a concrete slab on the ground. Tower cranes are a type of balance crane, meaning they form a T-shape. The counterweight is attached to one end of the horizontal piece and the hook is attached to the other end, which extends farther from the vertical portion of the crane. The operator's cab sits at the intersection of the crane.

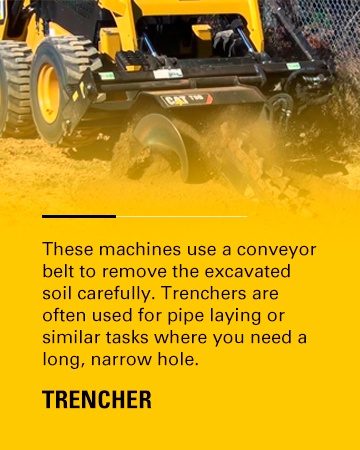

28. Trencher

It's no surprise that trenchers are used for digging trenches. They don't only dig, though. These machines use a conveyor belt to remove the excavated soil carefully. Trenchers are often used for pipe laying or similar tasks where you need a long, narrow hole. A trencher can be outfitted with different digging devices depending on the situation. For example, a trencher may use a metal chain to tear up the ground. This chainsaw-like device doesn't have to pause for small rocks or roots in its path.

29. Utility Vehicle

Utility type vehicles (UTVs) are a broad category of vehicles intended for work purposes rather than on-road passenger applications. Construction workers use these vehicles to move around a large job site quickly or haul small loads of materials or equipment from place to place. Utility vehicles are a versatile and helpful asset to have for many different jobs that extend beyond the construction industry, including agriculture and other fields.

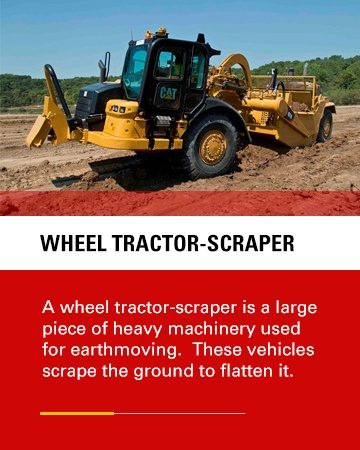

30. Wheel Tractor-Scraper

A wheel tractor-scraper is a large piece of heavy machinery used for earthmoving. As the name suggests, these vehicles scrape the ground to flatten it. The "wheel tractor" part refers to the front of the machine, which is simply a wheeled tractor. The rear part is where the scraping components are. What makes a wheel tractor-scraper unique is that it collects dirt rather than just moving it. As a blade cuts and loosens the soil, a conveyor belt moves the soil up into a hopper.

Visit The Cat® Rental Store for Your Construction Equipment Needs

There are many types of construction equipment suited for a wide variety of applications, even those not included on this list. Renting can be a cost-effective and convenient way to get the equipment you need without having to make a permanent investment. This is a strategic choice whenever you need a machine or attachment you don't expect to use repeatedly or when you're completing work out of town and don't want to transport equipment to the job.

When you need quality rental construction equipment, visit The Cat® Rental Store. With more than 1,300 locations across the globe, The Cat Rental Store is here for you wherever you're located. Caterpillar has been a trusted name in construction equipment for close to a century, so you can rely on Cat equipment to help you get the job done safely and efficiently.

Our dealers offer an extensive variety of construction equipment so you can be prepared for any job. Browse equipment online or call us at 1-800-RENT-CAT for more information or to request a quote on pricing.

Find The Cat Rental Store Near You

Related Posts

Tips for Construction Equipment Rental

Renting equipment can sometimes be overwhelming with all the choices, terms, and paperwork. At The Cat Rental Store, we make renting easy. Read on to learn more!

Read More

How to Be Sure Your Construction Equipment Is the Right Size

An important factor to consider when choosing equipment is the size of the machine. Learn how to find the right machine with The Cat Rental Store.

Read More

6 Considerations for Renting Construction Equipment

Many factors go into renting the right equipment — from project needs to to fuel costs to operator experience. Learn more with The Cat Rental Store.

Read More

How Small Construction Firms Benefit From Renting Equipment

Small businesses can especially benefit from the flexibility and versatility of renting equipment. Learn more benefits of renting with The Cat Rental Store.

Read More